-

CFRP/Al蜂窝复合材料由表面碳纤维夹层和铝合金材质窝芯构成,这种结构除了可提高对裂纹扩展的耐受性外,叠层还具有刚度比高、可成形性强以及良好的抗疲劳性、可修复性、抗冲击强度、耐腐蚀性和耐火性等优点[1]。然而,由于蜂窝复合材料在其生产制造过程中受加工工艺和人为不可控因素影响,加之常工作于高速、高压等恶劣的环境下,很容易产生各种结构缺陷,如脱粘、积水、裂纹和塌陷等[2]。因此,使用可靠的无损检测技术是确保材料在制造和使用过程中的性能和结构安全不可或缺的方法。

主动红外热波成像检测技术作为一种新兴的无损检测技术,具有检测面积大、检测速度快、非接触、无污染和无需耦合等优点。其中,脉冲热波成像(Pulsed Thermography, PT)[3]和锁相热波成像(Lock-in thermography, LIT)[4]研究较早,应用最广泛。此外,脉冲相位热波成像(Pulse Phase Thermography, PPT)[5]利用类似于PT的激励热流,运用快速傅里叶变换提取相位特征,PPT是对PT技术的改进,在一定程度上降低了检测结果对激发能量的依赖性。尽管如此,PT依赖更高峰值的激励源,LIT检测效率低,PPT存在检测深度太浅的问题。基于以上不足,近年来该领域提出基于动态热波成像的多种检测技术,其在光热系统的时域和频域性能改善方面更为显著,以克服与传统主动热波成像技术相关的问题(或试图将LIT的高信噪比水平的优势与PT可获得关于被测结构大量信息的优势相结合)。其中,脉冲压缩技术的应用提高了动态热波成像模式的检测效率,典型的例子有线性调频热波成像(Linear Frequency Modulation Thermal Wave Imaging, LFMTWI)和数字调频热波成像(Digital Frequency Modulated Thermal Wave Imaging, DFMTWI)[6],DFMTWI通过将数字调频热波和频域光热辐射物理学相结合,可实现脉宽与频率相互独立以及扩展探测深度或深度分辨率动态范围。目前DFMTWI的实现方法主要是采取编码形式,最常见的编码类型为巴克编码[7]和格雷编码[8](Golay Coded),其中巴克编码激励可以提高脉冲压缩(PuC)后获得的热谱序列中的缺陷检测能力,PuCT激励方案可有效地抑制噪声,提高热对比度,从而提高缺陷的信噪比,为材料中更深层次的缺陷检测提供有益的帮助。

在热波信号处理上,快速傅里叶变换是在频域中过滤所需频率分量的最常用的工具之一,并且它可以通过使用合适频带的啁啾热波激励用于热波雷达成像(Thermal Wave Radar Imaging, TWRI)的深度分辨率异常检测[9]。然而,快速傅里叶变换只能在时域或频域处理热波雷达信号,此外,希尔伯特变换和基于线性调频的Z变换技术也用于提高TWRI和调频热波成像(Frequency Modulated Thermal Wave Imaging,FMTWI)的异常检测能力和深度分辨率[10]。但亚表面缺陷深度分辨率与外部激励的调制探测频率及其通过后处理的分析有关,不充分的频率分辨率将导致一些细节丢失。因此,在TWRI或FMTWI应用中,需要尝试新的热波信号分析技术来提高缺陷检测能力和深度分辨率。文中提出运用三维匹配滤波器(3-Dimensional Matched Filter, 3D-MF)针对巴克编码调制信号激励所得图像序列进行处理,以克服传统处理方法的局限性,比如低功率或不充分的频率分辨率导致一些细的节丢失等,从而提高缺陷检测能力和深度分辨率。

在文中研究中,巴克编码调制信号被用来检测同时含有脱粘和积水缺陷的CFRP/Al蜂窝板,提出运用3D-MF对所得图像序列进行处理,通过三维截面剖析温度分布和信噪比比较,定量分析了不同匹配滤波器的可检测性和可靠性。

-

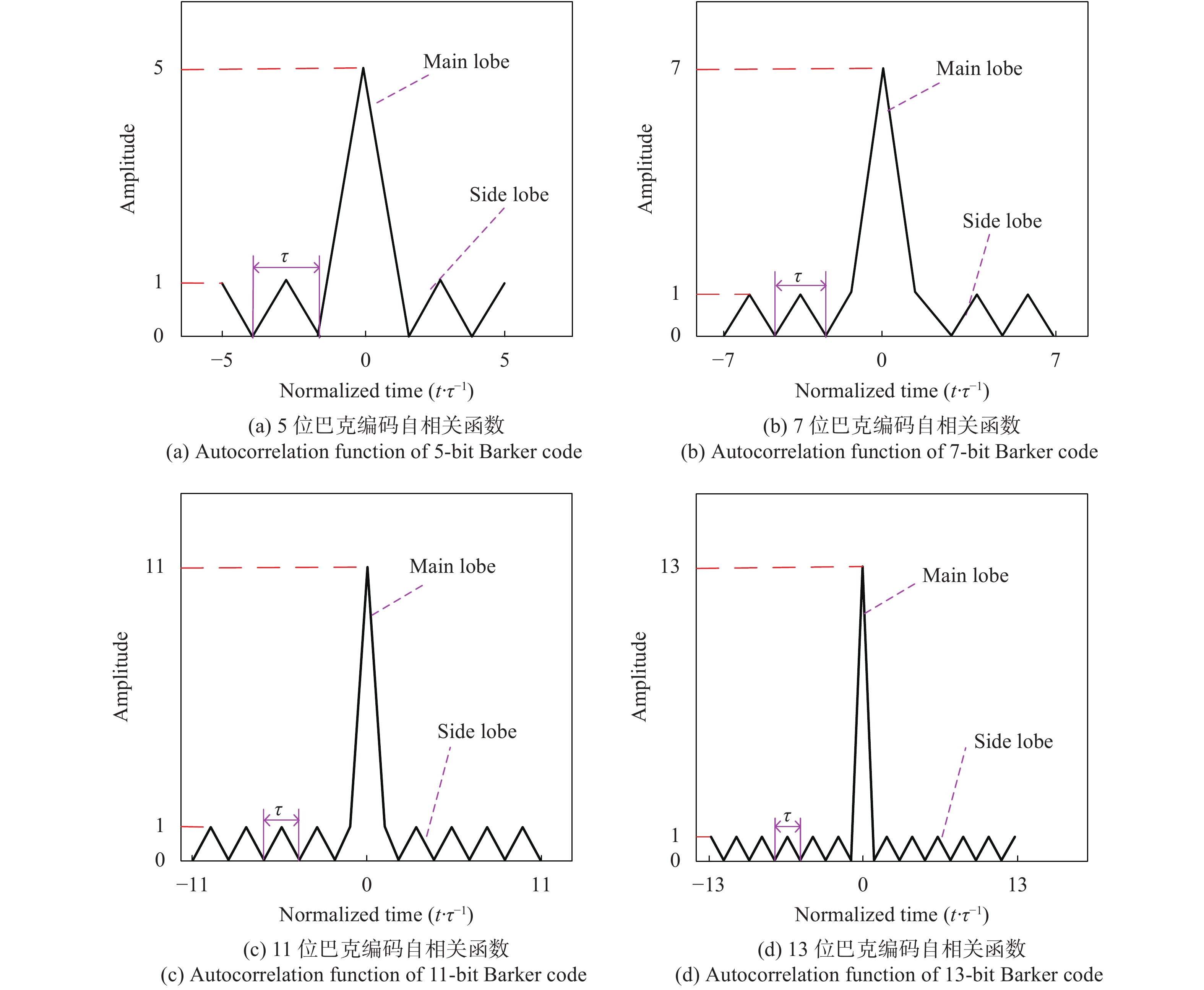

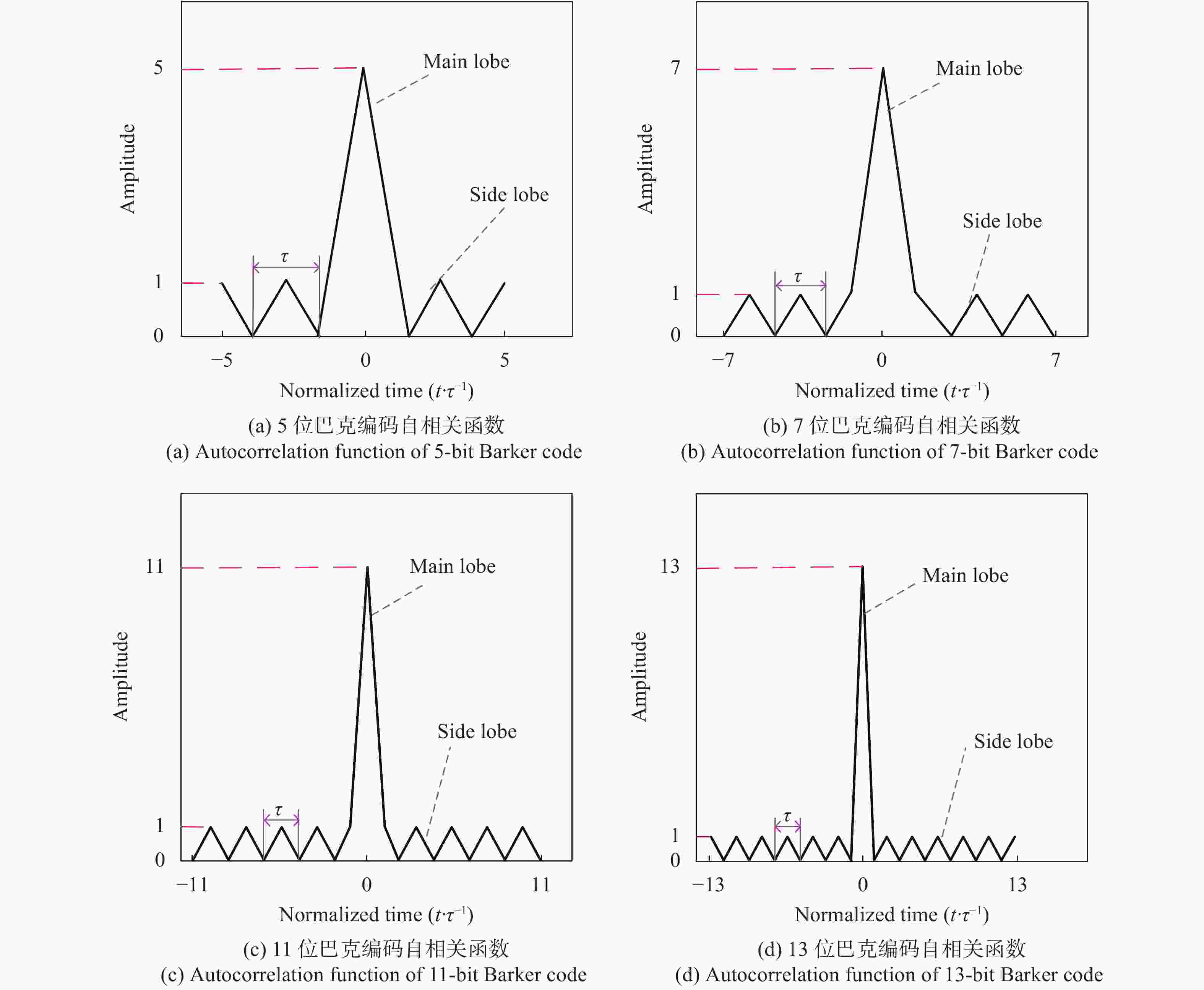

热波雷达成像技术通过应用脉冲压缩调制热激励源,克服了传统热波成像和激光热成像的缺点。结合试件缺陷的多样性,在研究中使用巴克编码信号来调制热激励源的强度,既满足不同缺陷尺寸必需的多频特性(FMTWI的特性),又满足了不同缺陷类型所需的衰减过程(PT的特性),此外还克服了PT对高功率峰值功率源的需求。巴克码是一种具有特殊规律的二进制码组,它是一个非周期序列,可提供最小的压缩旁瓣,比其他调制方案更容易产生,该代码可以在其自相关中给出与代码长度成比例的压缩比。此外,它在非周期/单触发模式下具有最佳的自相关特性,其自相关函数定义为:

$$R({{j}}) = \sum\limits_{t - 1}^{N - {{j}}} {{X_i}} {X_{i + j}} = \left\{ \begin{gathered} \begin{array}{*{20}{c}} \begin{gathered} n, \\ \begin{array}{*{20}{c}} 0&{or}&{ \pm 1,} \end{array} \\ \end{gathered} &\begin{gathered} j = 0 \\ 0 < j < n \\ \end{gathered} \end{array} \\ \begin{array}{*{20}{c}} {0,}&{\begin{array}{*{20}{c}} {\begin{array}{*{20}{c}} {}&{\begin{array}{*{20}{c}} {}&{} \end{array}} \end{array}}&{j \geqslant n} \end{array}} \end{array} \\ \end{gathered} \right.$$ (1) 式中:N代表巴克码的码长。

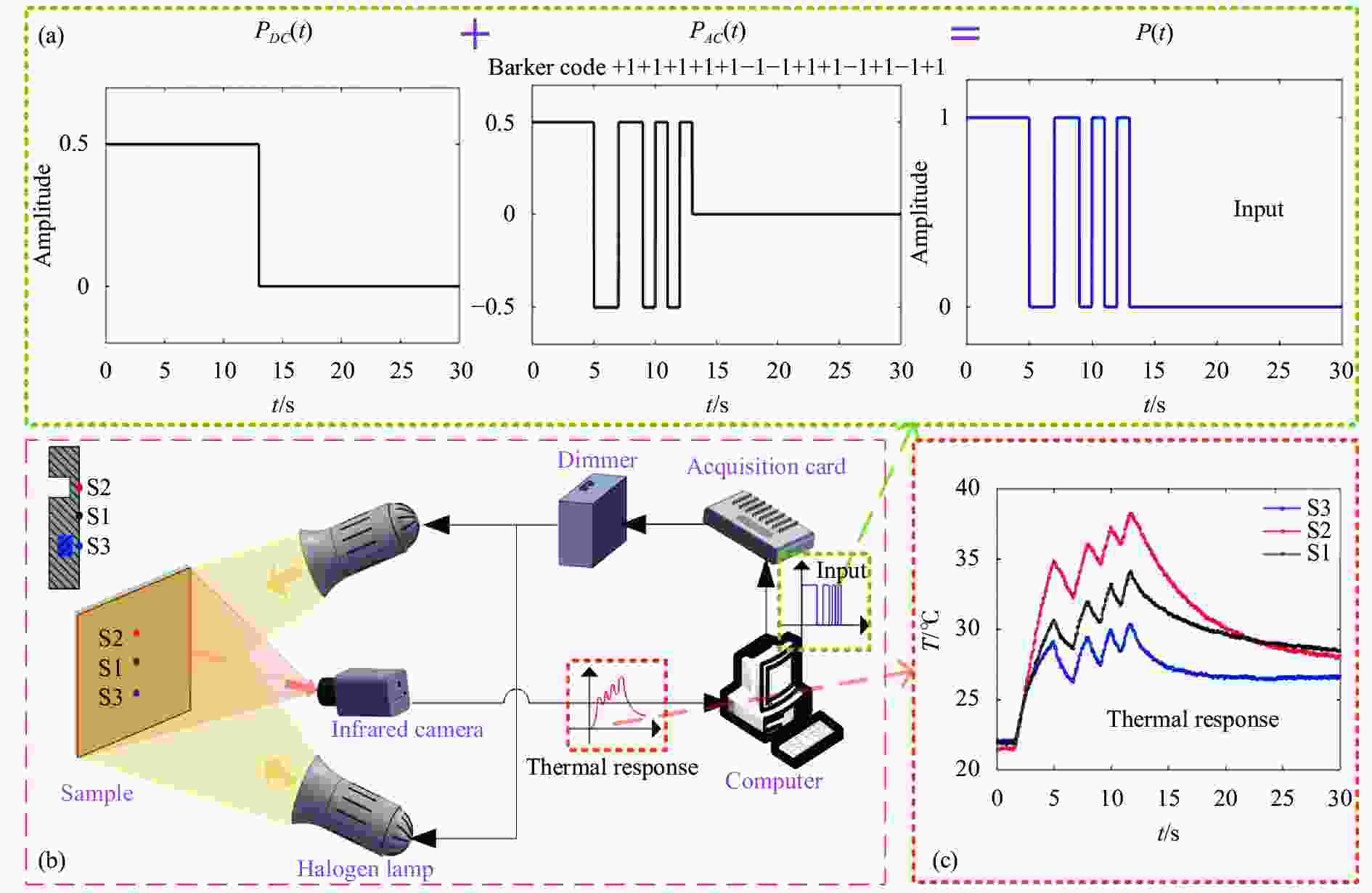

代码长度的选择是实验时间和所需旁瓣减少之间的折衷。在热成像环境中,过多的实验时间削弱了该技术的优势(快速),而较短的实验时间可能需要高峰功率热源。为了获得最佳响应,需要使用合适的代码长度和实验时间。如图1所示,根据自相关函数关系,因为总能量守,相比于其他6种小位数巴克码,13位巴克编码可提供现有最大的主旁瓣比和更宽的频带,从而实现能量利用最大化,更适合于低功率热源检测,或有很好的深度分辨率的优点。采集时间为30 s,既保证足够的激励时间又留有足够的延迟空间和衰减过程。所以选用13位巴克编码调制激励信号,即实际热激励时间为13 s,采集时间为30 s,既保证足够的激励时间又留有足够的延迟空间和衰减过程。

此外,在红外热波成像中应用巴克编码调制信号时,面临一个缺乏双极激励光源的实际问题,常用的激励源多为单极热源,即对试件进行双极激励是很难实现的。为解决以上问题,如图2(a)所示,利用线性叠加原理,引入阶跃函数

${P_{DC}}(t)$ ,使目标函数在所有情况下满足$P(t) \geqslant 0$ ,以实现巴克编码调制信号成功应用在单极光源激励的实验中。巴克编码调制激励信号可以表示为:$$\begin{split} \\ P(t) = {P_{DC}}(t) + {P_{AC}}(t) \end{split}$$ (2) 式中:

$P(t)$ 为目标信号;${P_{DC}}(t)$ 为阶跃信号;${P_{AC}}(t)$ 为动态信号即巴克编码信号,此外为了确保检测中波形的完整性,实验中${P_{DC}}(t)$ 幅值应设置为略大于${P_{AC}}(t)$ 。红外无损检测系统如图2(b)所示,计算机设置激励信号参数,再由数据采集卡产生相应热激励信号,经过调光器的作用使卤素灯产生所需功率的热流并作用于被测试件表面,被测试件与红外热像仪距离为300 mm,采用型号为A655SC的红外热像仪采集红外图像序列,像素大小为480×640,采样频率20 Hz,采样时间30 s。所得热波响应如图2(c),其中S1(黑色曲线),S2(红色曲线)和S3(蓝色曲线)对应图2(b)中试件缺陷设置S1,S2和S3,分别表示无缺陷区域、脱粘缺陷区域和积水缺陷区域。

-

三维匹配滤波器与图像融合具有相同的目的,但是采用了截然不同的方法来组合图像,如图3所示,它不是选择具有最精细细节的图像,而是在图像序列中选取含所需目标特征的图像,使用目标像素的光谱反射矢量同时观察图像序列。应用过滤器通过光谱特征识别物理元素,将序列中图像逐帧(

${P_1} \sim {P_n}$ )比对,然后在创建输出图像($P$ )时使用此比对信息。通过最大化与目标相似的光谱矢量的输出值,最小化与背景相似的光谱矢量,来组合光谱波段的信息。这是通过将图像序列的每个像素光谱矢量乘以矢量${\boldsymbol{q}}$ 来实现的,矢量${\boldsymbol{q}}$ 将光谱带信息集中为一个值。如图中所示4种不同滤波器(SMF, SAM, MSF, CEM)在用于确定${\boldsymbol{q}}$ 的方法上有所不同(详见文章第3节)。但均符合以下两种常规模型:第一种是线性相加模型,它被定义为:

$${\boldsymbol{x}} = \varepsilon {\boldsymbol{s}} + {\boldsymbol{w}}$$ (3) 式中:

${\boldsymbol{x}}$ 为给定像素的观测光谱矢量;${\boldsymbol{s}}$ 为目标光谱;${\boldsymbol{w}}$ 为背景光谱;$\varepsilon $ 为目标的光谱量度。该模型中的每个像素都是添加到背景中的缺陷点光谱的量度。用目标点权重表示高或低,分别表示缺陷存在或不存在。第二个模型将每个像素描述为可能的缺陷和背景光谱的混合物,如下所示:

$$\begin{split} \\ {\boldsymbol{x}} = {\boldsymbol{HA}} \end{split}$$ (4) 式中:

${\boldsymbol{H}}$ 为具有表示已知缺陷或背景光谱的列的矩阵;${\boldsymbol{A}}$ 为丰度矩阵,其定义了${\boldsymbol{H}}$ 对应${\boldsymbol{x}}$ 中的每个像列素的权重。与第一种模型的不同之处在于,着重点不是最大化或最小化缺陷点和背景的输入,而是估计每个像素中存在的每个输入光谱的百分比。这两个模型依赖于目标光谱的先验知识。第一种使用单个恒定目标光谱,而第二种使用矩阵中的多个目标光谱。每一个都必须由用户或其他预处理步骤提供。

在匹配滤波器检测器中,希望最大化

$\varepsilon {\boldsymbol{s}}$ ,同时通过乘以某个向量${\boldsymbol{q}}$ 来最小化${\boldsymbol{w}}$ 的影响[11]。这表现为:$${{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{x}} = \varepsilon {{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{s}} + {{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{w}}$$ (5) 公式(3)的情况,当背景被结构化时,通常需要乘以一个矩阵

${\boldsymbol{Q}}$ 来包含结构信息,在这种情况下笔者得到:$${\boldsymbol{Qx}} = \varepsilon {\boldsymbol{Qs}} + {\boldsymbol{Qw}}$$ (6) 然后选择匹配滤波器检测器,以便

$\left\| {{{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{w}}} \right\|$ 或者$\left\| {{\boldsymbol{Qw}}} \right\|$ 尽可能接近于零。希望找到一个矢量${\boldsymbol{q}}$ ,该矢量将最大化缺陷光谱的点积,同时最小化背景谱的点积。 -

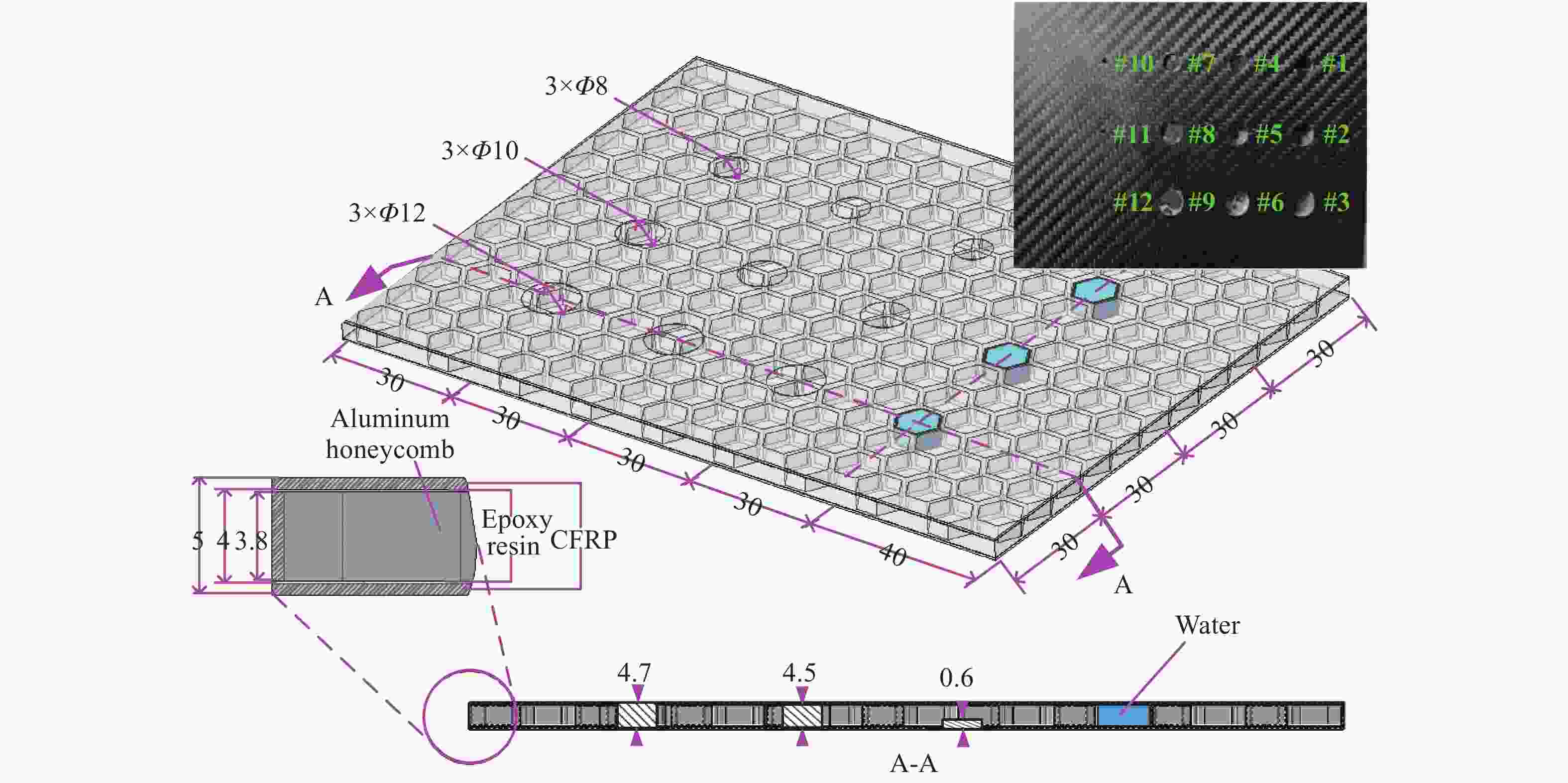

CFRP/Al蜂窝板由两层粘结剂将上下蒙皮与蜂窝芯粘接而成,其中蒙皮为厚度0.5 mm的碳纤维;蜂窝芯的网格边长为5 mm,整体厚度为3.8 mm的铝;粘接剂为厚度0.1 mm的环氧树脂。表1为各材料热物理参数。如图4所示,采用圆柱形孔模拟蜂窝板内部脱粘缺陷,其中#1~#3、#4~#6、#7~#9孔的深度分别为4.7 mm、4.5 mm和0.6 mm,分别模拟上蒙皮与窝心、窝心与环氧树脂及环氧树脂与下蒙皮的脱粘缺陷;#10~#13的3个孔直径为2 mm,深度为1 mm,作为注水孔,模拟积水缺陷。

表 1 材料热物理参数

Table 1. Material thermophysical parameters

Material Thermal conductivity/W·(m·K)−1 Density/kg·m−3 Specific heat capacity/J·(kg·K)−1 Aluminium 249.5 2769 877.87 Epoxy resin 0.251 2170 740 Carbon fiber 4.18 1550 793 Water 0.6 1000 4180 设置初始温度T0为293.15 K,传热系数h为10 W/(m2·K),采样频率20 Hz,加热时间30 s,热流功率为400 W/m2,定义温度差为:

$$\Delta T({{t}}) = {T_2}(t) - {T_1}(t) = \frac{Q}{{\sqrt {\pi k\rho ct} }}{{e}^{ - \frac{{{\mu ^2}}}{{\alpha t}}}}$$ (7) 式中:Q为表面吸收的能量,J;e为材料的热发射率,定义为

$e = \sqrt {k\rho c} $ ;$\alpha = k/\rho c$ ,α为材料热扩散系数,m3/s;ρ为材料密度,kg/m3;c为比热容,J/(kg·K);μ为截面厚度,mm。当μ=0时,此时

$\Delta T$ 表示上表面温度,即$\Delta {T_{{\rm{suf}}}}\left( t \right)$ 改写为下式:$$\Delta {T_{{\rm{suf}}}}\left( t \right) = \frac{Q}{{e\sqrt {\pi t} }}$$ (8) 试件表面受到热激励后,热波向内部传输,只考虑一维的情况下,

$\Delta T$ 表面测量温差达到最大时刻时,如式所示:$$t = \frac{{2{d^2}}}{\alpha }$$ (9) 式中:d为缺陷深度,mm。

将最大时刻t代入至

$\Delta T$ 中,可获得最大温差$\Delta {T_{\max }}$ 与缺陷深度d之间的关系如下式所示:$$\Delta {T_{\max }}\left( t \right) = \frac{Q}{{\rho cd\sqrt {2\pi } }}{{e}^{ - \frac{1}{2}}}$$ (10) 因此,深度值越大的缺陷其检测难度也越大。选出相应热通量Q,以及最大温差值

$\Delta {T_{\max }}$ ,即能够实现材料内部缺陷定量化的识别。 -

热波响应性质与雷达信号处理的相似性使得红外无损检测采用三维匹配滤波处理所得数据。

-

公式(3)中确定

${\boldsymbol{q}}$ 的最简单方法是使用已知的缺陷点光谱。在简单匹配滤波器(Simple Matched Filter,SMF)中使用缺陷点光谱${\boldsymbol{s}}$ 作为${\boldsymbol{q}}$ 结果,得到公式(11):$$SMF = {{\boldsymbol{s}}^{\rm{T}}}{\boldsymbol{x}} = \sum\limits_{i = 1}^L {{s_i}} {x_i}$$ (11) 式中:

$L$ 为输入图像序列的帧数。但上述方法往往会受到被定义为

$\sqrt {{{\boldsymbol x}^{\rm{T}}}{\boldsymbol x}}$ 的背景能量的很大影响,因为通常缺陷处和背景之间的能量差异很大。消除这种影响的一种方法是将结果减去背景的能量,即除去${\boldsymbol{s}}$ 的能量,将测量${\boldsymbol{s}}$ 和${\boldsymbol{x}}$ 之间的多维角度,这被称为SAM检测器。 -

光谱角度图[12](Spectral Angle Map, SAM)将SMF除以两个矢量幅度,这样就有一个无量纲标量输出,可以解释为

${\boldsymbol{s}}$ 和${\boldsymbol{x}}$ 之间角度的余弦,而不是点积量。如公式(12)所示:$$ SAM = \frac{{{{\boldsymbol{s}}^{\rm{T}}}{\boldsymbol{x}}}}{{\left\| {\boldsymbol{s}} \right\| \times \left\| {\boldsymbol{x}} \right\|}} = \frac{{{{\boldsymbol{s}}^{\rm{T}}}{\boldsymbol{x}}}}{{\sqrt {{{\boldsymbol{s}}^{\rm{T}}}{\boldsymbol{s}}} \sqrt {{{\boldsymbol{x}}^{\rm{T}}}{\boldsymbol{x}}} }}$$ (12) -

匹配子空间滤波器(Matched Subspace Filter, MSF)在已知k个目标光谱t1,t2,...,tk的情况下,将其堆积成列,横跨目标子空间而形成矩阵

${\boldsymbol{H}}$ =[t1,t2,···,tk],MSF是使用${{\boldsymbol{x}}^{\rm{T}}}{{\boldsymbol{P}}_{\boldsymbol{H}}}{\boldsymbol{x}}$ ,对投射到目标空间的${\boldsymbol{x}}$ 的能量进行评估,其中${{\boldsymbol{P}}_{\boldsymbol{H}}} = {\boldsymbol{H}}{\rm{(}}{{\boldsymbol{H}}^{\rm{T}}}{\boldsymbol{H}}){{\boldsymbol{H}}^{\rm{T}}}$ 是正交投影矩阵,得到:$${\rm MSF} = {{\boldsymbol{x}}^{\rm{T}}}{{\boldsymbol{P}}_{\boldsymbol{H}}}{\boldsymbol{x}}$$ (13) -

约束能量最小化[13](Constrained Energy Minimization, CEM)类似于多尺度函数,用已知背景和目标光谱,抑制不需要的特征能量,希望得到最小化滤波器输出能量,使得输出y为:

$${y_j} = \sum\limits_{j = 1}^L {{{\boldsymbol{q}}_j}} {{\boldsymbol{x}}_{ij}} = {{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{x}}_i^{\rm{T}} = {\boldsymbol{x}}_i^{\rm{T}}{{\boldsymbol{q}}^{\rm{T}}}$$ (14) 使得

${{\boldsymbol{q}}_{\min }}\{ {{\boldsymbol{q}}^{\rm{T}}}{\boldsymbol{\varGamma }}{\boldsymbol{q}}\}$ 满足${{\boldsymbol{s}}^{\rm{T}}}{\boldsymbol{q}} = 1$ ,其中

${\boldsymbol{\varGamma }} = \dfrac{1}{N}\displaystyle\sum\limits_{i = 1}^N {{{\boldsymbol{x}}_i}} {\boldsymbol{x}}_i^{\rm{T}}$ 。得到最优解${\boldsymbol{q}} = \dfrac{{{{\boldsymbol{\varGamma }}^{ - 1}}{\boldsymbol{s}}}}{{{{\boldsymbol{s}}^{\rm{T}}}{{\boldsymbol{\varGamma }}^{ - 1}}{\boldsymbol{s}}}}$ ,代入公式(14)得:$${\rm CEM} = \frac{{{{\boldsymbol{s}}^{\rm{T}}}{{\boldsymbol{\varGamma }}^{ - 1}}{\boldsymbol{x}}}}{{{{\boldsymbol{s}}^{\rm{T}}}{{\boldsymbol{\varGamma }}^{ - 1}}{\boldsymbol{s}}}}$$ (15) -

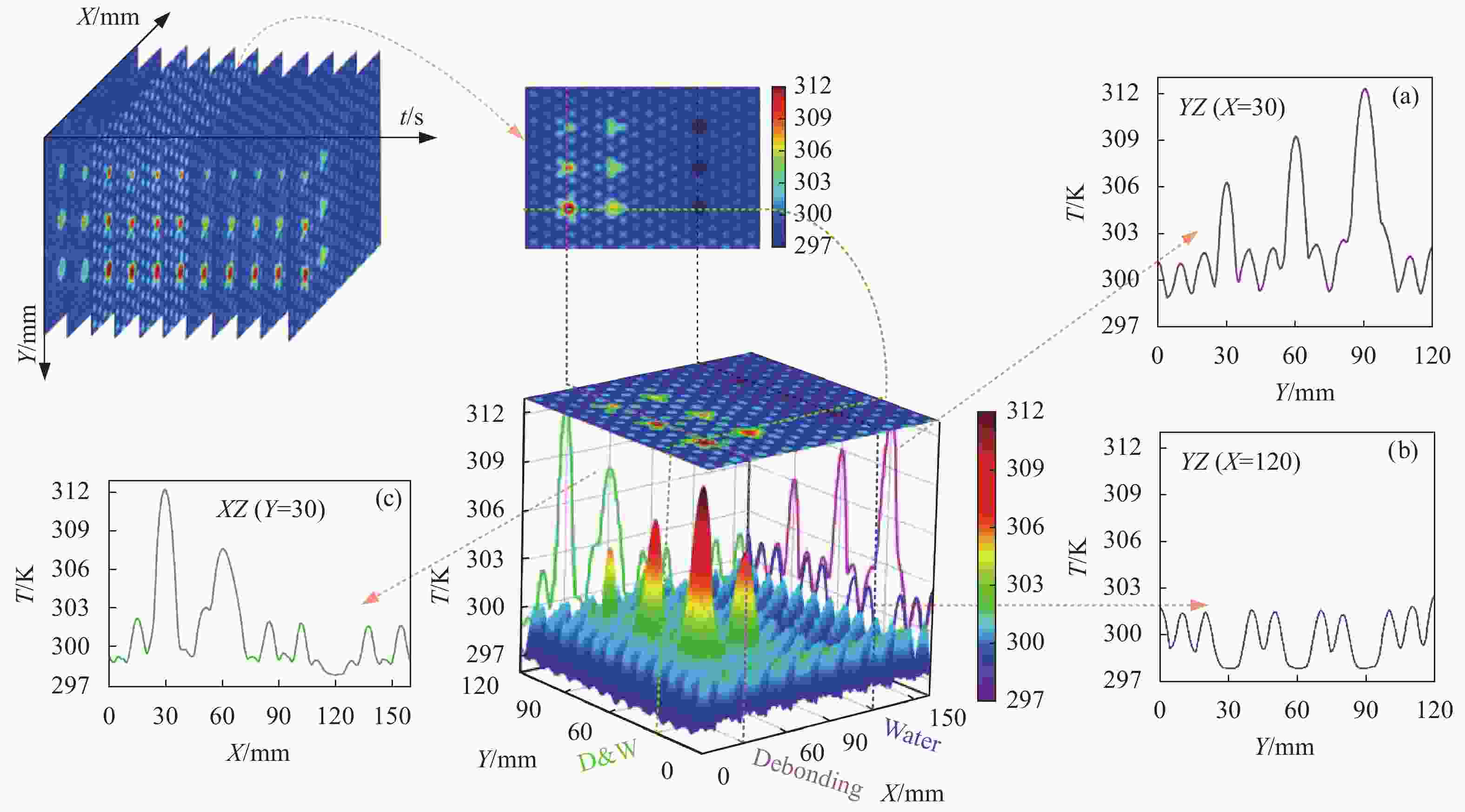

如图5所示,在仿真图像序列中选取温差△T最大时刻温度云图进行分析。为使结果更加直观明了,将二维温度云图转化为三维可视化温度分布图,并针对不同缺陷类型分别做了三维截面分析,即:图5(a)中曲线表示同一深度不同直径的脱粘缺陷(#1~#3)所在直线的瞬时温度分布;图5(b)中曲线表示3个积水量相同的积水缺陷(#10~#12)所在直线的瞬时温度分布;图5(c)表示不同缺陷类型、深度及直径的缺陷(#3、#6、#9和#12)所在直线的瞬时温度分布。

-

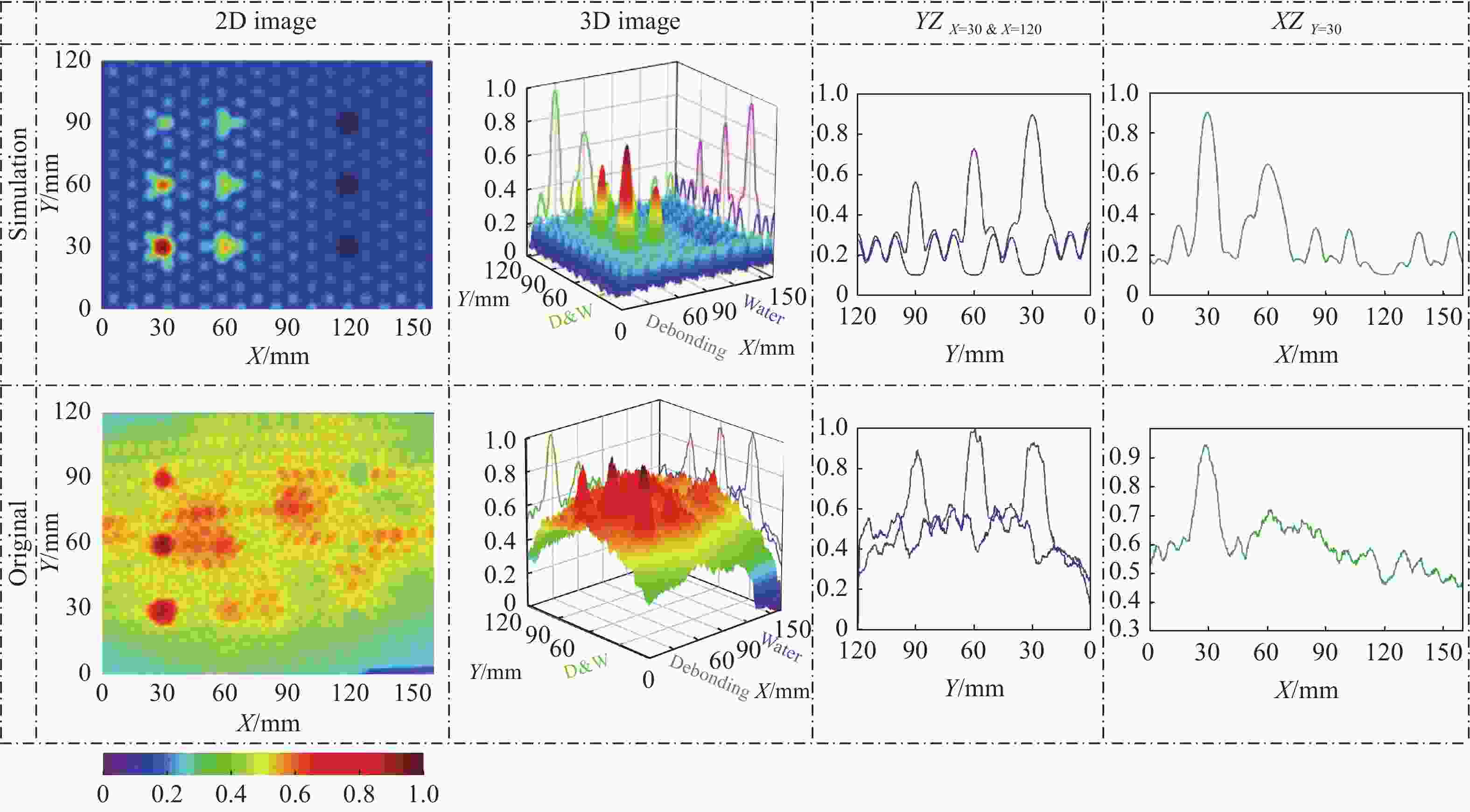

基于上述分析方法,将实验所得图像序列中温差最大一帧图像做相同处理,且出于直观观察和定量比较的目的,将所得数据进行线性归一化处理后与仿真进行比较,结果如图6所示,可以总结为:(1)从2D image中很容易发现实验与仿真相符的是,第一列(X=30)缺陷明显,且直径从上往下依次增大;第三列(X=90)因其缺陷深度较小,所以检测效果并不明显。不同的是,相较仿真,实验所得原始云图的第二列和第四列(X=60和X=120)缺陷显示不是很理想。(2)从3D image中可以看出,整体温度分布以一定规律显现,表现为脱粘处凸起,积水处凹下。此外,由于卤素灯光源能量分布是由中心向周围扩散,所以实验三维温度整体也呈现出中心凸起现象。(3)从YZ(X=30 & X=120)中,实验虽然与仿真有相似的脱粘(粉色)凸起和积水(蓝色)下凹的规律,但并未呈现出随着缺陷尺寸发生变化的现象,主要体现在脱粘缺陷。(4)从XZ(Y=30)中,可以看出相较仿真第二列脱粘缺陷(X=60),实验并没有明显体现。

-

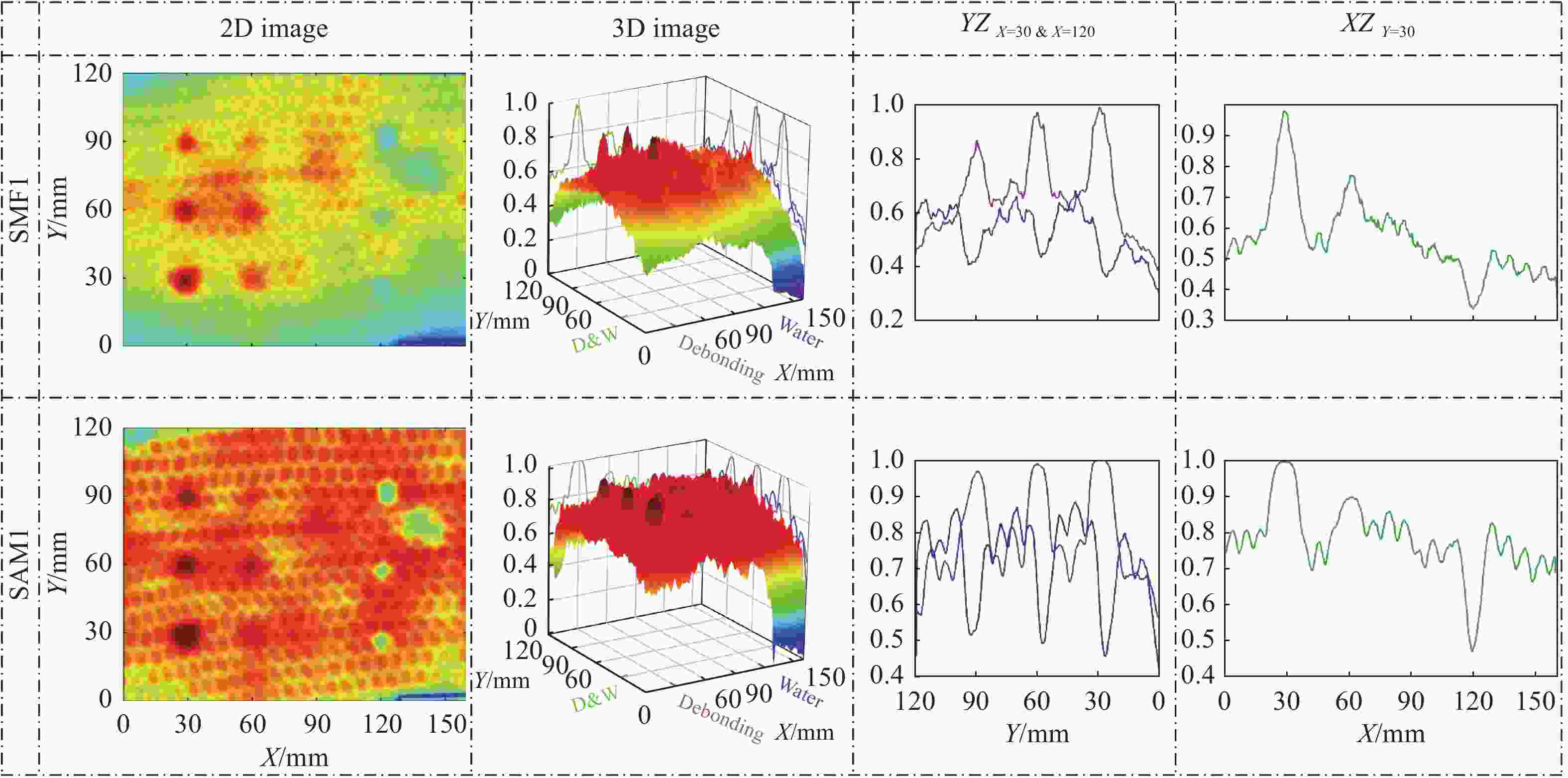

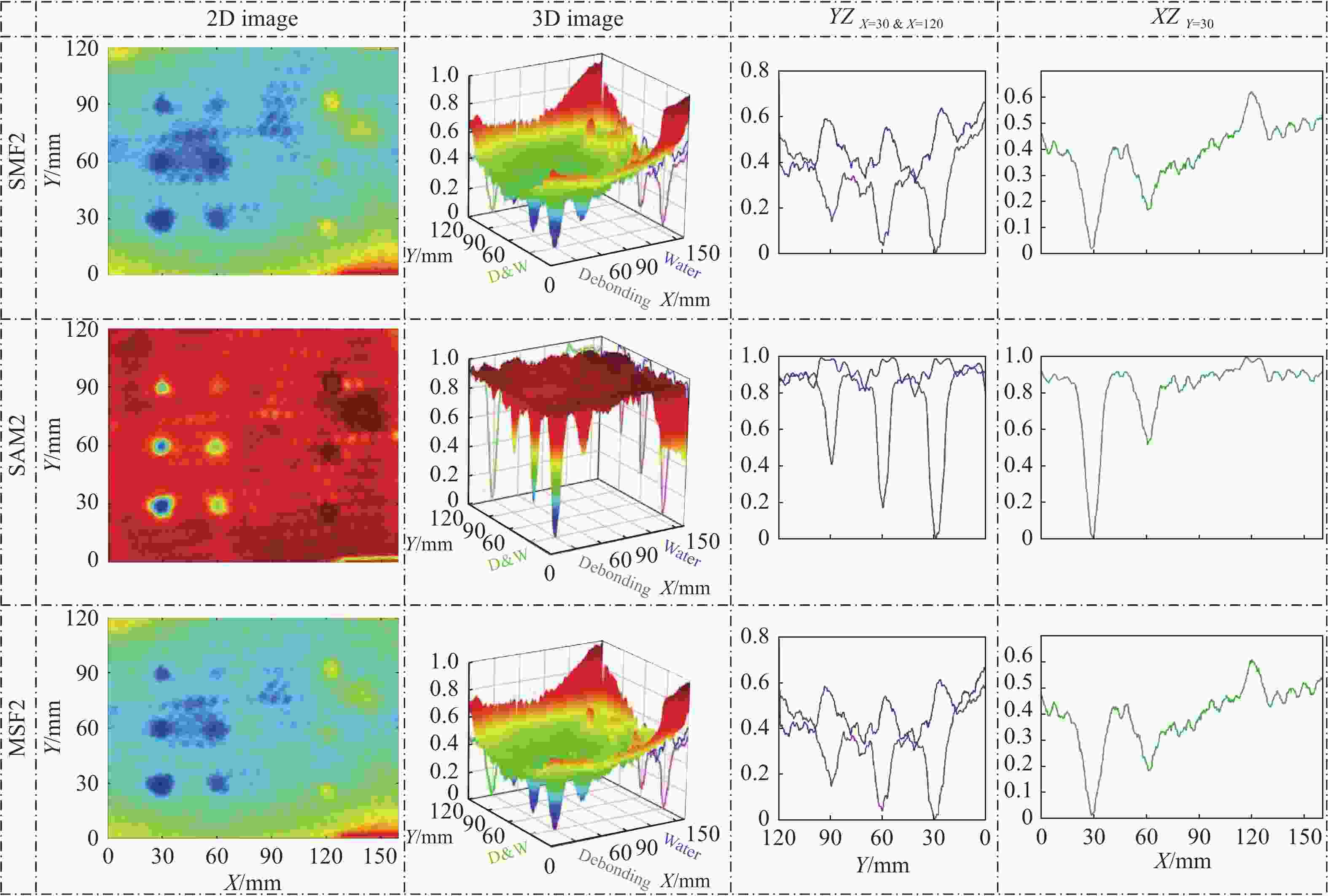

图7为以脱粘点为目标的不同匹配滤波器算法处理结果。相较于图6中实验:(1) 2D image中对于第二列(X=60)和第四列(X=120)缺陷,4种算法处理后均有不同程度改善,其中CEM针对第四列效果略显不足。(2) 3D image中,可以看出算法对背景均有抑制作用,光源能量问题导致中心凸起现象有所改善,显著体现于CEM,且CEM的温度跨度最为明显。(3)从YZ(X=30 & X=120)和XZ(Y=30)中可以看出,对于脱粘(粉色结合绿色),其随直径变化的规律也均有所体现,且第二列缺陷也明显化,其中CEM最为明显,SAM略有不足。对于积水(蓝色结合绿色),效果最佳的是SAM,相反CEM最差。

图 7 以脱粘缺陷为目标的算法处理结果对比

Figure 7. Results comparison of algorithms with debonding defect as the target

图8为以积水点为目标的不同匹配滤波器算法处理结果。结合上述分析可以看出图8整体温度与图7呈反向分布,匹配滤波器的机理导致这一现象的产生,因为两次选择的目标温度不同,且前一次大于背景温度,而后一次则小于背景温度。尽管如此,这并不影响笔者分析缺陷的类型或尺寸。从图中可以看出,相较于以脱粘为目标,以积水为目标的脱粘缺陷效果更为突出,4种算法均可得到随直径变化的规律(粉色),当然第二列(X=60)的缺陷也有明显显示(绿色)。但值得注意的是,以积水点为目标的处理结果积水效果并不理想,甚至差于以脱粘为目标。

-

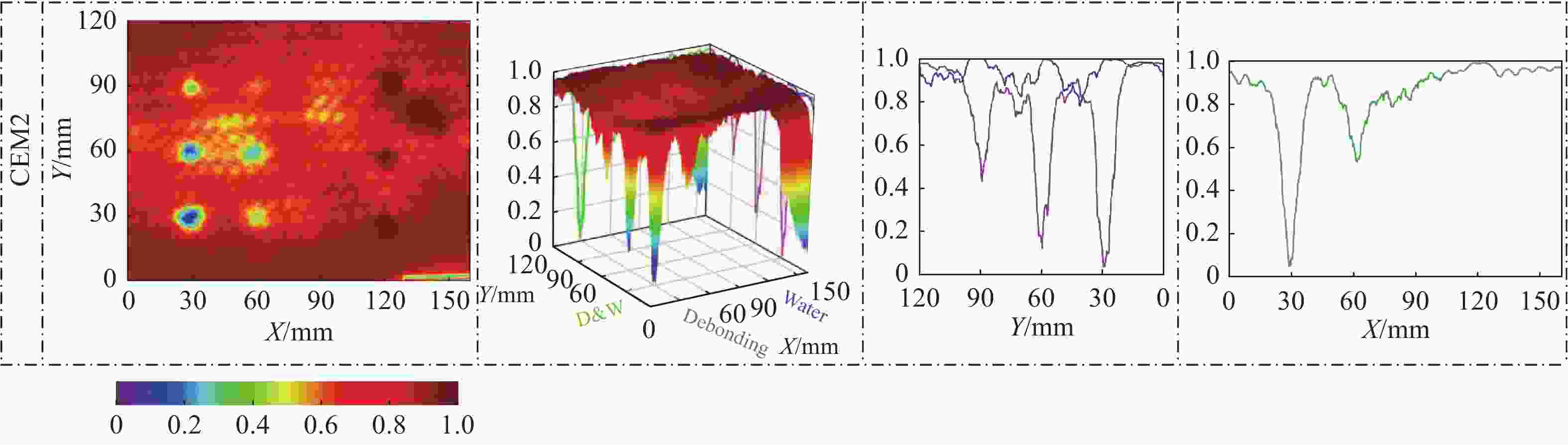

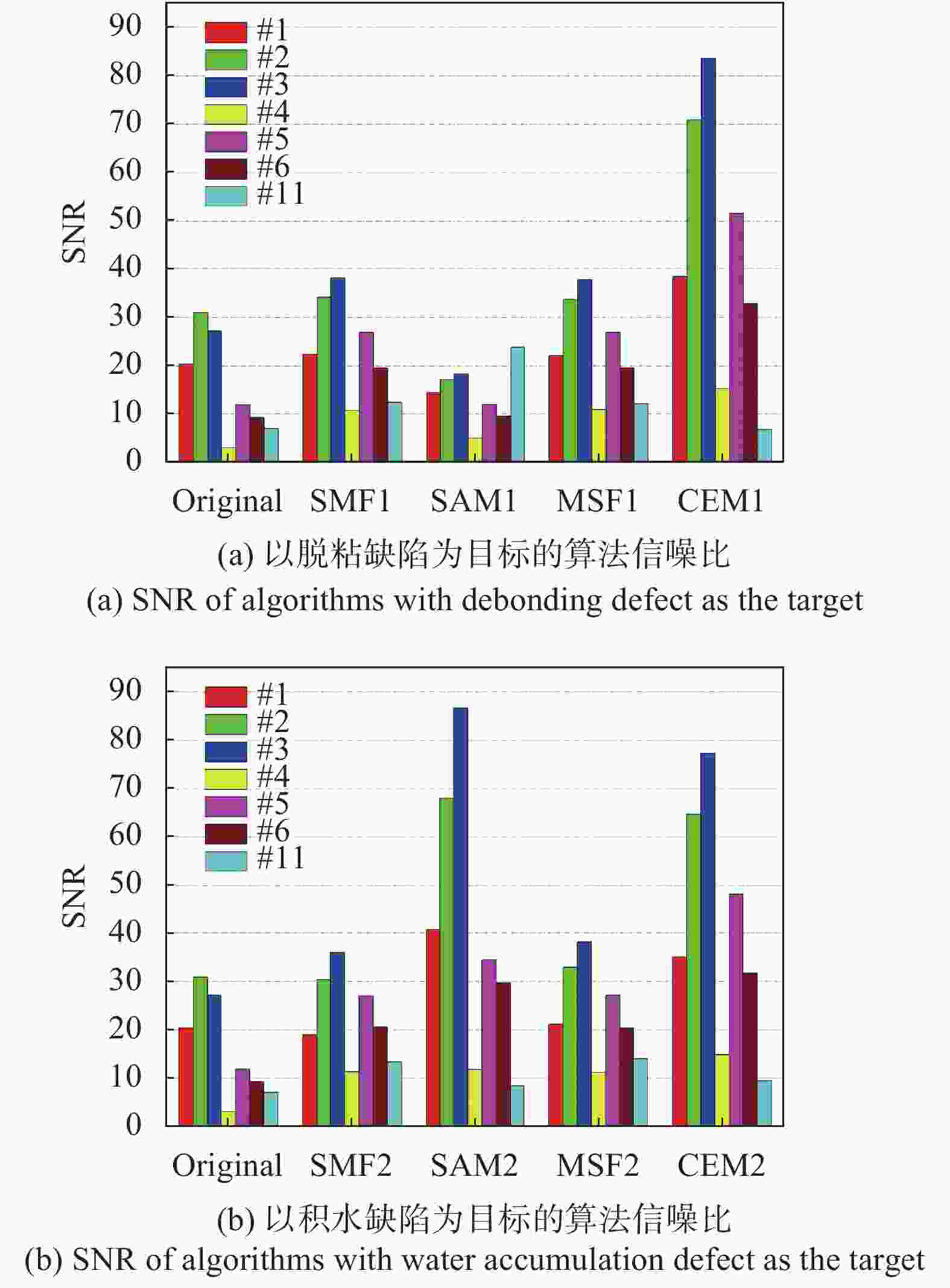

出于直观观察和定量比较的目的,首先对检测图像进行线性归一化处理,然后进行信噪比评估。如图9选取脱粘缺陷#1~#6和积水缺陷#11中心点与背景参照点的信噪比值(SNR)作为衡量不同算法对实验结果影响的标准,选择的缺陷区域和非缺陷区域均包含10×10 pixel。在此基础上信噪比被定义为公式(16)[14]:

$${\rm SNR} = \frac{{\left| {T - R} \right|}}{{{\sigma ^2}}}$$ (16) 式中:SNR为目标处信噪比;σ2为目标处数据标准差;R为背景温度数据;T为目标处温度数据。

在上述条件下,不同滤波器及不同目标选取处理结果的信噪比比较如图10所示,其中图10(a)为以脱粘点为目标处理结果与原始热图信噪比,相应图10(b)为以积水点为目标处理结果与原始热图信噪比。从图10(a)中可以明显看出,对于脱粘缺陷(#1~#6),CEM具有较高的信噪比值,相反最低信噪比值的是SAM,然而值得注意的是对于积水缺陷(#11),SAM却表现出了最高的信噪比值。这就说明以脱粘为目标处理的情况下,CEM检测脱粘缺陷效果最好。此外,值得注意的是针对积水缺陷,SAM有着很好的检测能力。在图10(b)中,相较于以脱粘为目标,以积水为目标的整体积水缺陷的信噪比值均较低,但对于脱粘缺陷信噪比值最高的是SAM,值得注意的是仅次于SAM的CEM,无论哪种目标选取方式,其都有较高的信噪比表现。

结合4.2节的分析结果,可以得出以下结论:对于脱粘缺陷,CEM表现得更为稳定,且有很强的抑制背景强度的性能。而对于积水缺陷,在选取脱粘为目标的情况下,其检测结果表现为4种算法均有所改善,其中SAM最为显著,而积水为目标时效果很不理想。

-

引入了一种低能量激发的巴克编码激励热成像技术,用于检测CFRP/Al蜂窝复合材料的结构脱粘或窝心积水缺陷。此外,着重引入并介绍了三维匹配滤波和基于滤波原理的目标或背景选取的基本原理,详细描述了4种特征匹配滤波子算法。随后进行了不同三维匹配滤波器算法的对比实验。实验结果表明,三维匹配滤波器具有良好的检测效果,在提高信噪比、减少背景噪声方面均有显著的效果,但前提是需要保证针对不同缺陷选择合适的目标。且不同算法所得结果也有差异,如SAM和CEM可有效抑制背景或噪声,使缺陷处温差更为明显、缺陷轮廓更为清晰,而SMF和MSF更为稳定,表现为对目标点的选取敏感度低。相反,SAM对目标点的选择更为敏感。总之,巴克编码激励结合了脉冲激励和锁相激励的优点,而三维匹配滤波器算法为低功率激励条件下的CFRP/Al蜂窝复合材料结构缺陷提供一种快速无损检测和热波成像方法。

Barker coded thermal wave detection and matched filtering for defects in CFRP/Al honeycomb structure

-

摘要: CFRP/Al蜂窝板构件长期服役于恶劣环境,易引发脱粘和积水等涉及运行安全的缺陷。以同时含有脱粘和积水缺陷的CFRP/Al蜂窝复合板材为检测试件,运用巴克编码调制脉冲压缩信号驱动卤素灯作为外部激励源,用红外热像仪采集试件表面的红外热图序列。设计并运用三维匹配滤波器对所采集的图像序列进行处理,在4种不同量化方式的条件下,获得有关脱粘和积水缺陷的8个热波响应结果,并对这些结果进行多角度对比分析及信噪比评估。结果表明:巴克编码激励具有调制简单、易实现等优势,结合三维匹配滤波器可有效抑制红外热图背景噪声和提高信噪比,能实现在低功率热激励条件下对复合材料内部脱粘和积水缺陷的有效检测。

-

关键词:

- 无损检测 /

- CFRP/Al蜂窝板 /

- 巴克编码调制信号 /

- 三维匹配滤波器 /

- 信噪比

Abstract: CFRP/Al honeycomb panel components have been used in harsh environment for a long time, which is easy to cause debonding and water accumulation and other defects related to operation safety. Taking CFRP/Al honeycomb composite plate with debonding and water accumulation defects as the test sample, the halogen lamp driven by Barker coded modulation pulse compression signal was used as the external excitation source, and the infrared thermal image sequence of the sample surface was collected by infrared camera. Three dimensional matched filter was designed and used to process the acquired image sequence. With 4 different quantization methods, 8 thermal wave response results of debonding and water accumulation defects were obtained, and these results were compared and analyzed from multiple aspects and the signal-to-noise ratio (SNR) was evaluated. The results show that Barker coded excitation has the advantages of simple modulation and easy implementation, and it can effectively suppress the background noise of infrared thermal image and improve the SNR by combining with three dimensional matched filter, and can effectively detect the internal debonding and water accumulation defects of composite materials under the condition of low-power thermal excitation. -

表 1 材料热物理参数

Table 1. Material thermophysical parameters

Material Thermal conductivity/W·(m·K)−1 Density/kg·m−3 Specific heat capacity/J·(kg·K)−1 Aluminium 249.5 2769 877.87 Epoxy resin 0.251 2170 740 Carbon fiber 4.18 1550 793 Water 0.6 1000 4180 -

[1] Thirukumaran M, Siva I, Jappes J W, et al. Forming and drilling of fiber metal laminates - A review [J]. Journal of Reinforced Plastics and Composites, 2018, 37(14): 981-990. doi: 10.1177/0731684418771194 [2] Vavilov V, Marinetti S, Pan Y, et al. Detecting water ingress in aviation honeycomb panels: Qualitative and quantitative aspects [J]. Polymer Testing, 2016, 54: 270-280. doi: 10.1016/j.polymertesting.2016.07.023 [3] Tang Q, Wang Y, Liu J, et al. Pulse infrared thermal imaging detection of internal defects in heat-resistant alloy coated structural plates [J]. Infrared and Laser Engineering, 2013, 42(7): 1685-1690. (in Chinese) [4] Moskovchenko A, Vavilov V, Bernegger R, et al. Detecting delaminations in semitransparent glass fiber composite by using pulsed infrared thermography [J]. Journal of Nondestructive Evaluation, 2020, 39(3): 61-57. doi: 10.1007/s10921-020-00705-1 [5] Maldague X, Marinetti S. Pulse phase infrared thermography [J]. Journal of Applied Physics, 1996, 79(5): 2694-2698. doi: 10.1063/1.362662 [6] Mulaveesala R, Venkata G. Coded excitation for infrared non-destructive testing of carbon fiber reinforced plastics [J]. The Review of Scientific Instruments, 2011, 82(5): 054902. doi: 10.1063/1.3594551 [7] Shi Q, Liu J, Liu W, et al. Barker-coded modulation laser thermography for CFRP laminates delamination detection [J]. Infrared Physics & Technology, 2019, 98: 55-61. [8] Mulaveesala R, Arora V. Complementary coded thermal wave imaging scheme for thermal non-destructive testing and evaluation [J]. Quantitative Infrared Thermography Journal, 2017, 14(1): 44-53. doi: https://doi.org/10.1080/17686733.2016.1229329 [9] Wang F, Wang Y, Liu J, et al. The feature recognition of CFRP subsurface defects using low-energy chirp-pulsed radar thermography [J]. IEEE Transactions on Industrial Informatics, 2020, 16(8): 5160-5168. doi: 10.1109/TII.2019.2954718 [10] Liu J, Liu X, Wang Y. Infrared thermal wave imaging detection technology based on chirp excitation [J]. Infrared and Laser Engineering, 2012, 41(6): 1416-1422. (in Chinese) [11] Hernandez-Beltran J E, Diaz-Ramirez V H, Juarez-Salazar R. Adaptive matched filter for implicit-target recognition: application in three-dimensional reconstruction [J]. Applied Optics, 2019, 58(32): 8920-8930. doi: 10.1364/AO.58.008920 [12] Li H, Hong Z, Han C, et al. Onboard spectral and spatial cloud detection for hyperspectral remote sensing images [J]. Remote Sensing, 2017, 10(1): 152. [13] Bustamante J, Aragonés D, Afán I, et al. Hyperspectral sensors as a management tool to prevent the invasion of the exotic cordgrass spartina densiflora in the doñana wetlands [J]. Remote Sensing, 2016, 8(12): 1001. doi: 10.3390/rs8121001 [14] Bu C, Liu G, Zhang X, et al. Debonding defects detection of FMLs based on long pulsed infrared thermography technique [J]. Infrared Physics & Technology, 2020, 104: 103074. -

下载:

下载: