-

低温辐射计[1-2]是一种用于物理学、工程与技术科学基础学科领域的计量仪器,其光谱范围覆盖真空紫外至远红外波段,已成为光度、光谱光度、光谱辐射度和激光功率、能量计量的基准,被许多国家标准实验室作为光度学和辐射度学的最高标准[3-12]。低温辐射计通常工作于液氦制冷温度(2~4 K),并处于超高真空度环境(低于10−6 Pa),进而有效地减小了接收腔与环境辐射能量的交换,使得低温辐射计的测量不确定度优于0.01%。

低温辐射计的吸收腔是其核心器件,要求对不同波长的入射辐射都表现出接近100%的吸收率,以确保完全光-热转换,提高测量准确度。影响吸收腔吸收率的因素很多,除与腔体自身结构和尺寸有关外,还受腔体内壁涂黑材料特性、入射光波长和空间分布情况等影响[13-14]。实际入射辐射进入吸收腔后,尽管吸收腔经过涂覆高吸收率黑涂层等表面处理技术可极大地提升吸收率,仍有部分辐射经由镜面/漫反射散逸到吸收腔外,因此需要准确测量吸收腔的吸收率,并对低温辐射计的功率测量结果进行修正。

吸收腔吸收率常规的测量方法主要是积分球法[15],即在室温条件下将单色光入射到积分球内,标准反射板作为参考标准与吸收腔交替放置在积分球出口,通过分别测量积分球上探测器的输出信号,得到吸收腔吸收率。但积分球法在低温环境下吸收腔涂层的吸收率受到温度波动的影响,室温条件下测量的吸收腔吸收率往往难以反应其低温特性,直接影响低温辐射计功率测量的准确度。为此,文中研究4 K低温辐射计吸收腔吸收率测试技术,通过在低温辐射计布儒斯特窗口前设计反射监测组件,分别测量吸收腔在室温和4 K条件下632.8 nm处的反射信号,结合传统积分球法在室温条件下吸收腔632.8 nm处反射率的测量结果,得到4 K条件下低温辐射计吸收腔的吸收率;通过研究4 K低温辐射计吸收腔吸收率测试技术,实现吸收腔吸收率的低温特性测量,对低温辐射计的功率测量结果进行进一步修正。测量结果表明:所研制的低温辐射计的吸收腔在4 K温度条件下的吸收率较室温条件下的吸收率发生了微小变化。

-

低温辐射计的工作原理如图1所示。将低温辐射计吸收腔内壁均匀喷涂无光谱选择性的碳纳米管材料,当有辐射到达吸收腔表面时,碳纳米管涂层吸收辐射,吸收腔温度升高,这种温升用温度传感器来测量,然后用加热器加热吸收腔,调节加热器电流使其产生的热量与吸收腔接收辐射时产生的热量相等,这时对吸收腔所加的电功率就等于吸收腔接收的辐射功率。

由于低温辐射计的吸收腔工作于4 K温度并且处于真空度达到10−6 Pa的环境下,减小了接收腔与环境辐射能量的交换,而且解决了常温条件下物质热性能问题,如吸收腔材料的热学特性发生巨大的变化,比热容减小三个量级,热导率提高几倍至十几倍,这样吸收腔的热扩散率就提高约四个量级,使得高吸收率、短时间常数的吸收腔成为可能;吸收腔的热扩散率提高后,腔体更容易达到热平衡,减小了电加热功率和光加热功率的热流通道的不一致造成的差异。

通过采取以上措施,可以使低温辐射计的灵敏度和准确度提高100余倍,达到的测量不确定度优于0.01%。低温辐射计作为光辐射基准,为了准确复现光功率值,需要对其光功率的测量结果进行修正,修正后的光功率为:

式中:

$ {P_{corr}} $ 为修正后的光功率;$ P $ 为低温辐射计测量得到的光功率;T为低温辐射计布儒斯特窗口透射率;A为吸收腔吸收率;S为进入低温辐射计的杂散光。以上几个修正因子中,布儒斯特窗口透射率与其本身的洁净度、窗口的角度调节、入射光线的偏振度等有关系,在每次低温辐射计工作前进行测量;杂散光在每次低温辐射计工作时利用四象限探测器同步进行测量;吸收腔吸收率仅在低温辐射计整机安装调试时进行测量,因此吸收腔吸收率的准确测量是非常重要的。

-

吸收腔结构及其内壁涂层材料的设计直接影响吸收腔的吸收率。目前,低温辐射计吸收腔多采用带斜底的圆柱腔,斜底角多为30°和60°。常用吸收腔涂黑材料有Chemglaze Z302、碳纳米管吸收黑和NiP黑。笔者研制的低温辐射计采用斜底角60°的吸收腔,腔内喷涂以碳纳米管材料为吸收剂、高分子材料为基体的功能性复合涂层。该涂层具有“微米-纳米”跨尺度的高孔隙率吸光结构,与低温辐射计工作波段的波长尺度相匹配,带隙分布展宽极大(0.1~4.0 eV),对低温辐射计工作波段均能表现出优良的吸收特性。

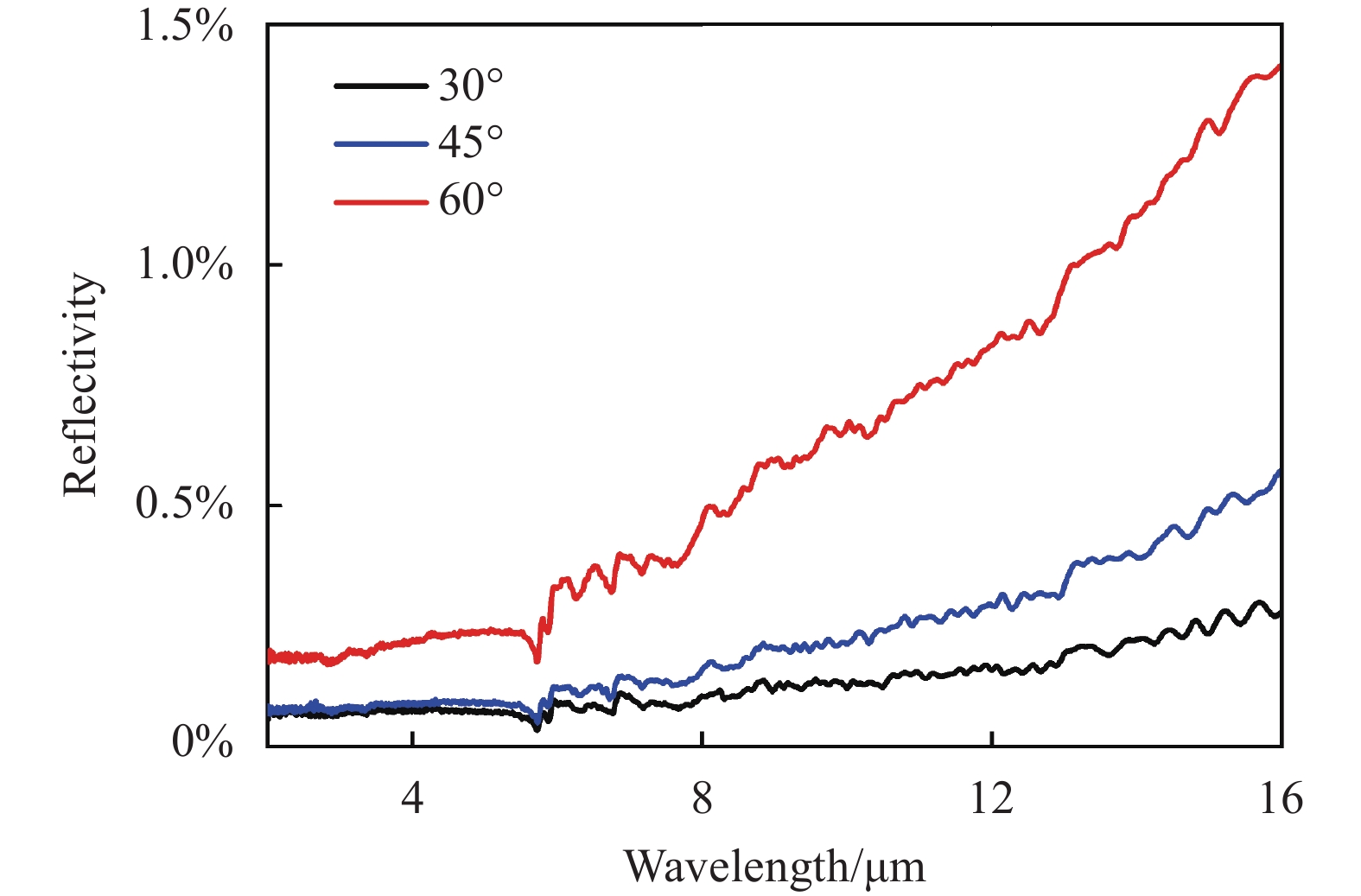

不同入射角条件下涂层光谱镜面反射率测量结果如图2所示。当入射辐射波长延伸到6 μm以上,材料吸收率随入射角增大而急剧降低,当波长延伸至16 μm,纳米涂层的反射率可高达1.3%。而随入射角的降低,纳米管阵列对光子的束缚能力大为提升,当入射角降低至30°,全波段反射率低至0.25%以下,满足低温辐射计的设计需求。

-

吸收腔涂层的高吸收能力主要源于两个方面:(1)涂层表面为多孔陷光结构,其结构尺度与目标光源的波长相匹配,实现高效吸收;(2)涂层以碳材料为主要吸收剂,该材料以sp2杂化轨道为主,拥有丰富的π电子,能够实现高效的电子光吸收跃迁。

笔者研制的低温辐射计工作温度为4 K,低温环境下可能会对上述两个过程产生微小影响,因此,吸收腔吸收率有微量变化。从介观尺度分析,涂层通过表面多孔陷光结构对目标波长的光进行吸收,在低温环境下,涂层由于热胀冷缩会出现微小的收缩现象,导致多孔陷光结构尺寸发生变化,使得其对目标波长光的吸收能力略有下降;从微观尺度分析,低温环境下的π电子在能带中的填充分布会发生变化,导致其受光激发的跃迁几率产生变化,对目标波长(623.8 nm)光的激发跃迁响应变差,使得其对目标波长光的吸收能力略有下降。

-

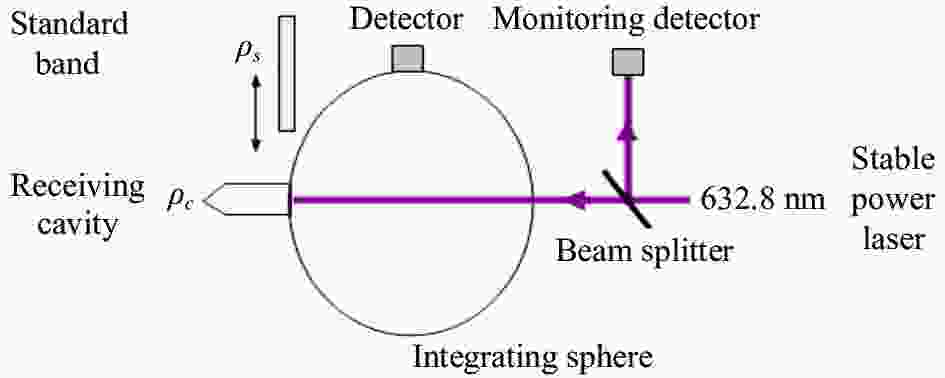

室温条件下吸收腔反射率的测量通常采用积分球法,如图3所示。吸收腔长度为40 mm、内径为10 mm、壁厚为0.1 mm、斜底角为60°,涂层材料在632.8 nm波长下的发射率为0.98。积分球直径为200 mm,内壁材料为聚四氟乙烯。积分球入口安装可变光阑,其最大直径为10 mm,积分球出口直径为10 mm。将标准板和吸收腔分别放置在积分球出口,632.8 nm的稳功率激光经过分束镜后反射部分由监视探测器接收用于监视激光的稳定性,透射部分经过积分球入口分别直接照射在标准板和吸收腔上,由积分球上的探测器在与入射光成90°角的位置上分别接收标准板和吸收腔的反射光信号,由于标准板反射率已知,于是计算得到吸收腔反射率为:

式中:

$ {\;\rho _c} $ 为吸收腔的反射率;$\; {\rho _s} $ 为标准板的反射率;$ {V_c} $ 为吸收腔放置在积分球出口时积分球上探测器输出的电信号;${V_s}$ 为标准板放置在积分球出口时积分球上探测器输出的电信号,$V_c'$ 为吸收腔放置在积分球出口时监视探测器输出的电信号;$V_s'$ 为标准板放置在积分球出口时监视探测器输出的电信号。测量时使用反射率标称值分别为0.99 和0.02的两块标准板,其中反射率为0.99的标准板经过中国计量院校准,其632.8 nm波长下的反射率值为0.990。测量时先用反射率为0.990的标准白板标定反射率为0.02的标准黑板,再用反射率为0.02的标准黑板标定吸收腔。

监视探测器进行激光功率稳定性的监测,监视探测器与积分球上的探测器同时采集信号,对吸收腔反射率的测量结果进行修正,使得激光光源的不稳定性对测量结果的影响进一步降低。

积分球上探测器输出的电信号和监视探测器输出的电信号分别经过各自的前置放大器由数字电压表测量。由于吸收腔反射信号极弱,且与标准板的反射信号相差104倍,因此对积分球上探测器的前置放大器的信噪比和动态范围要求很高,项目设计采用超低噪声电流放大器,放大器采用高速电路技术来设计,尽量降低电源纹波,灵敏度范围覆盖1 V/pA~1 V/mA,可调的噪声截止频率范围覆盖0.01 Hz~1 MHz。

-

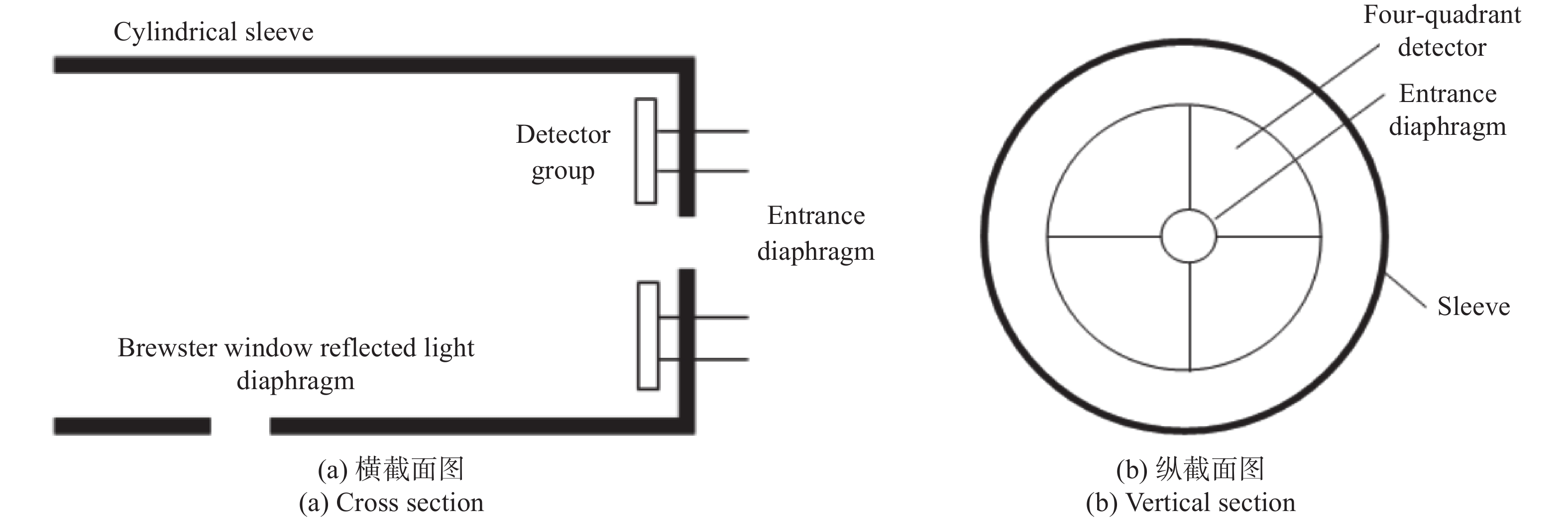

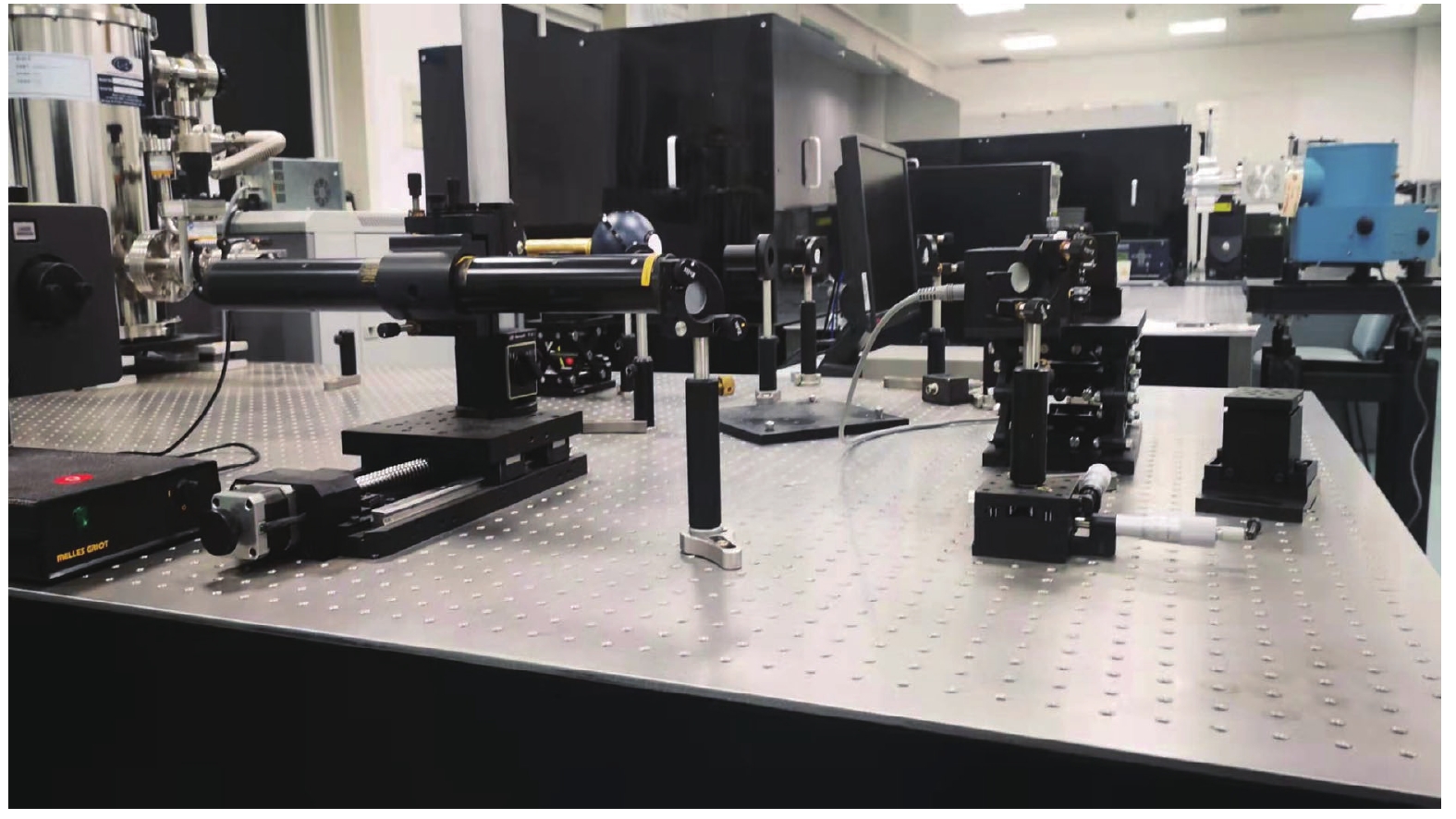

利用如图4、图5所示的反射监测组件,开展不同温度条件下吸收腔吸收系数测量实验,测量原理如图6所示。在室温条件下,将反射监测组在件安装低温辐射计布儒斯特窗口前,632.8 nm的稳功率的激光依次经过反射监测组件的入射光阑和布儒斯特窗后入射到低温辐射计的吸收腔内,调节布儒斯特窗的姿态调整机构,使激光经布儒斯特窗反射的光最弱,透过布儒斯特窗的光绝大部分被吸收腔吸收,极小一部分反射光透过布儒斯特窗由反射监测组件内的四象限探测器接收,四象限探测器的输出信号经过前置放大器后由数字电压表测量电压值,记为V。调节低温辐射计制冷机的制冷温度,利用反射监测组件测量不同温度条件下吸收腔反射光信号大小VT。

Figure 6. Principle diagram of the absorption coefficient measurement of the absorption cavity under different temperature conditions

计算得到不同温度T下吸收腔的反射率:

吸收腔在任意温度T的吸收率为

$1 - {\rho _{\rm T}}\left( \lambda \right)$ 。 -

(1)反射率测量实验结果

如图7所示,对低温辐射计吸收腔的反射率进行了测量,测量过程中激光功率的稳定性在0.5 h内优于5×10−5。根据中国计量科学研究院出具的校准证书,标准板在632.8 nm波长下的反射率为0.990,吸收腔反射率测量结果如表1所示。

Number of measurements $\dfrac{ { {V_c} } }{ { {V_s} } }$ $\dfrac{ {V_s'} }{ {V_c'} }$ $ \;{\rho _c} $ $ \;{\rho _c} $ average $ \;{\rho _c} $ experimental standard deviation $ 1 - \;{\rho _c} $ 1 0.0002375 0.99992 0.0002351 0.000 2417 5.3×10−6 0.99976 2 0.0002418 0.99994 0.0002394 3 0.0002502 0.99991 0.0002477 4 0.0002392 0.99992 0.0002368 5 0.0002408 0.99995 0.0002384 6 0.0002415 0.99993 0.0002391 7 0.0002398 0.99994 0.0002374 8 0.0002518 0.99992 0.0002493 9 0.0002483 0.99996 0.0002458 10 0.0002502 0.99995 0.0002477 Table 1. Summary of measurement results of the reflectivity of the absorbing cavity

(2)吸收率测量实验结果

如图8所示,通过调节低温辐射计工作温度从室温到4 K,分别测量反射监测组件输出的信号值,得到吸收腔吸收率测量结果如表2所示。测量时,四象限探测器测量的背景平均值为0.002616 mV,室温条件下四象限探测器测量的信号平均值为0.033568 mV,4 K条件下四象限探测器测量的信号平均值为0.027561 mV,信噪比优于10。实验结果表明:所研制的低温辐射计吸收腔吸收率在4 K温度条件较室温条件发生了微小变化,与吸收腔涂层吸收特性的分析结果一致,实际使用时需要对低温辐射计的功率测量结果进行进一步修正。

Figure 8. Physical diagram of the absorbing cavity absorptivity measurement device under variable temperature conditions

Number of measurements $\dfrac{ { { {{V} }_{\text{T} } } }}{ { { {{V} }_{} } } }$ $ {\rho _c}\left( {632.8} \right) $ ${\rho _{_{\rm{ T}}} }\left( {632.8} \right)$ 1−${\rho _{_{\rm {T} } } }\left( {632.8} \right)$ 1−${\rho _{_{\rm {T}}} }\left( {632.8} \right)$ average 1−${\rho _{_{\rm {T}}} }\left( {632.8} \right)$ experimental

standard deviation1 1.208611 0.0002417 0.0002921 0.9997079 0.99971 2.2×10−5 2 1.213973 0.0002934 0.9997066 3 1.223985 0.0002958 0.9997042 4 1.213982 0.0002934 0.9997066 5 1.209048 0.0002922 0.9997078 6 1.223989 0.0002958 0.9997042 7 1.234034 0.0002983 0.9997017 8 1.213992 0.0002934 0.9997066 9 1.228026 0.0002968 0.9997032 10 1.209935 0.0002924 0.9997076 Table 2. Summary of the measurement results of the absorbing cavity absorptivity

-

4 K条件下吸收腔吸收率的测量不确定度可用4 K条件下吸收腔反射率的测量不确定度表征。4 K条件下吸收腔反射率测量的模型如公式(3)所示,通过分析,4 K条件下吸收腔吸收率的测量不确定度分量主要有:

(1) 室温条件下反射率测量对4 K条件下吸收腔吸收率测量引入的测量不确定度分量u1;

(2) 室温条件下四象限探测器V测量对4 K条件下吸收腔吸收率测量引入的测量不确定度分量u2;

(3) 4 K条件下四象限探测器VT测量对4 K条件下吸收腔吸收率测量引入的测量不确定度分量u3;

(4) 测量重复性引入的测量不确定度分量u4。

(1) u1

反射率测量数学模型如公式(2)所示,通过分析,

$\; {\rho _c} $ 的测量不确定度主要受$ \;{\rho _s} $ 、$ {V_c} $ 、$ {V_s} $ 、$V_s'$ 、$V_c'$ 的影响。根据校准证书,标准板反射率为0.990时,$ {\rho _s} $ 引入的测量不确定度$ \Delta {\rho _s} $ 为5×10−3,标准板反射率对吸收腔反射率测量引入的测量不确定度为:$ {V_s} $ 、$V_s'$ 、$V_c'$ 对吸收腔反射率测量引入的测量不确定度主要受数字电压表电压测量的影响。根据校准证书,数字电压表的相对测量不确定度$ \Delta {V_s} $ 为0.005%(k=2),经过分析,Vs、Vs'、Vc' 对吸收腔反射率测量引入的测量不确定度均为6.0×10−9。由于 $ {V_c} $ 较$ {V_s} $ 、$V_s'$ 、$V_c'$ 的大小低了四个数量级,因此$ {V_c} $ 对吸收腔反射率测量引入的测量不确定度除了受数字电压表的影响,还受前置放大器换挡误差以及探测器非线性的影响。经过分析,$ {V_c} $ 对吸收腔反射率测量引入的测量不确定度为1.3×10−5。根据表1反射率测量重复性为5.3×10−6,则测量重复性引入的测量不确定度为1.7×10−6。通过对以上不确定度来源进行合成,并且灵敏系数VT/V为1.22,得到室温条件下反射率测量对4 K条件下吸收腔吸收率测量引入的测量不确定度u1为2×10−5。(2) u2

根据校准证书,数字电压表的测量不确定度为0.005% (k=2),吸收腔的反射率为0.0002417,灵敏系数VT/V为1.22,因此 V测量引入的测量不确定度u2为8×10−9。

(3) u3

根据校准证书,数字电压表的测量不确定度为0.005% (k=2),吸收腔的反射率为0.0002417,灵敏系数VT/V为1.22,因此 VT测量引入的测量不确定度u2为8×10−9。

(4) u4

根据重复性实验,测量重复性引入的测量不确定度u4为7×10−6。

通过对以上各测量不确定度来源进行分析,其不确定度分析详见表3,4 K条件下吸收腔吸收率的测量不确定度为0.005% (k=2)。

Uncertainty component Standard uncertainty Evaluation method Uncertainty component introduced by absorptivity measurement u1 0.2×10−4 Type B Uncertainty component introduced by the output V of the detector u2 8×10−9 Type B Uncertainty component introduced by the output VT of the detector u3 8×10−9 Type B Uncertainty component introduced by measurement repeatability u4 0.07×10−4 Type A Combined standard uncertainty 0.22×10−4 Relative combined standard uncertainty 0.0022% Relative expanded uncertainty(k=2) 0.005% Table 3. Analysis of measurement uncertainty

-

文中通过在低温辐射计布儒斯特窗口前设计反射监测组件,结合传统积分球法在室温条件下吸收腔632.8 nm处反射率的测量结果,实现4 K条件下低温辐射计吸收腔吸收率的测量,其相对测量不确定度为0.005% (k=2),解决了低温辐射计工作温度条件下吸收腔吸收率的测量问题,对低温辐射计的功率测量结果进行进一步修正,使得低温辐射计功率测量结果更加准确。

Measurement technique research for the absorptivity of cryogenic radiometer absorbing cavity at the 4 K temperature

doi: 10.3788/IRLA20210984

- Received Date: 2021-12-17

- Rev Recd Date: 2022-01-10

- Accepted Date: 2022-01-13

- Publish Date: 2022-09-28

-

Key words:

- cryogenic radiometer /

- absorbing cavity /

- reflectivity /

- absorptivity

Abstract: In order to realize measuring the absorptivity of cryogenic radiometer absorbing cavity at the 4 K temperature, a method of measuring the absorptivity with variable temperature is researched. By designing reflection monitoring components in front of the Brewster window of the cryogenic radiometer, and controlling the cryogenic radiometer to work in a vacuum environment of 10−6 Pa, then adjusting the refrigeration temperature of the cryogenic radiometer, the reflection signals of the cryogenic radiometer absorbing cavity are measured at 632.8 nm under room temperature and different temperature conditions. Combined with the measurement results of the reflectance at 632.8 nm of the cryogenic radiometer absorbing cavity at room temperature using the traditional integrating sphere method, the absorptivity of the cryogenic radiometer absorption cavity can accurately obtain under different temperature conditions through calculations. The experimental measuring the absorptivity of the absorbing cavity at room temperature and 4 K temperature, the absorptivity is 0.99976 and 0.999 71, respectively. The measurement uncertainty of the absorptivity of the cryogenic radiometer absorption cavity at the 4 K condition is evaluated, and the results obtained show that the relative expanded uncertainty is 0.005%(k=2).

DownLoad:

DownLoad: