-

中红外波段(3~5 μm)的固体激光器是以玻璃、晶体等固体材料为工作物质的激光器,具有对比度高及高湿度条件下穿透能力强且具备结构紧凑、小巧、牢固、灵活等优点,在遥感、通信、激光雷达及军事等诸多领域都有重要的应用价值和前景[1-2]。

目前,对中红外波段固体激光器的可靠性研究方面,国内外学者主要集中在激光晶体的热效应研究上[3-6],如不同条件下固体激光器的热效应及其对器件性能的影响,并探讨了通过解析分析、测量热透镜效应等验证激光介质温度分布的试验验证方法;聂志强用有限元法对高功率半导体激光器进行模拟分析,研究不同温度条件下激光器互联界面的寿命[7];彭勃等人采用对数分布统计分析方法计算了半导体激光器在不同温度下的平均寿命,并对加速寿命器件进行了不同时期的失效分析[8]。在可靠性研究方面,有学者将盲元作为器件性能退化或失效的一种表现形式[9],苑利钢[10]等人在固体中红外激光的输出方面探讨了产生不同输出功率和微米级别激光的光转化效率;张利明[11]讨论了掺杂过渡金属离子的中红外固体激光器输出激光波长范围;牛海莎[12]等人通对激光器内部增益调制产生的偏振跳变现象提取双折射信息,进而获得应力;朱凡[13]等建立了高精度激光光束准直系统,进一步提高激光光束精度;缪存孝[14]等针对高精度电流控制和磁场干扰问题,设计了一种激光器恒流源驱动和交流控温系统提升其工作可靠性。

目前,国内外学者对中红外波段固体激光器振动可靠性研究非常少,国内有学者通过对固体激光器样机进行振动冲击试验[15],利用接触式测量方法,验证了其抗振设计的有效性,国外对于中红外固体激光器振动可靠性研究方面则未见相关报道。与此同时,以往的接触式传感器测振方法需要将加速度传感器附着在被测试物体上,这种测试方法存在质量和刚度上的附加问题,对测量结果的准确性产生影响,文中利用激光多普勒效应非接触式的测振方法,改变传统传感器所带来的附加干扰问题,振动测量结果会更准确。事实上,中红外固体激光器对光学晶体组件的振动可靠性要求更高,各个部件不仅在距离上要保持精确位置,而且光路上必须同轴,否则,任何一个部件的偏离,都会改变激光器的输出参数。而中红外固体激光器主要应用于机载和车载的谐振环境,在使用过程中易发生共振,引起光路发生畸变,导致激光器性能下降或者失效。现阶段,针对光学晶体组件的振动特性研究国内外还未见报道,亟需一种准确有效获取其实际工况下振动响应的分析方法,作为激光器敏感光学组件失效分析和可靠性评价的一种手段。

-

中红外固体激光器核心结构如图1所示,该激光器由3部分组成:半导体激光器、Tm:YAP激光器和OPO谐振腔。其中半导体激光器是由激光二极管单元(LD)、光纤(Fiber)和耦合器(Coupler)组成,它的输出波长为793 nm,光纤输出的半导体激光通过耦合器后聚焦在激光晶体Tm:YAP上;Tm:YAP激光器是由Tm:YAP激光晶体、声光调制器(AO)和谐振腔镜(M1和M2)组成;OPO谐振腔则是由腔镜(M3和M4)和磷锗锌晶体(ZGP)组成。耦合器将半导体激光耦合到Tm:YAP晶体上,产生2 μm激光;再通过整形器(Reshaping system)将激光耦合到磷锗锌晶体上,最终产生3~5 μm激光。改类型激光器的输出功率为3 W,泵浦光功率为30 W,用半导体制冷和强制风冷相结合的散热方式,其晶体尺寸为Φ5×20 mm。

-

使用UG建立激光器机头实体模型,然后导入ANSYA分析软件,运用 ANSYS参数化设计语言 APDL对模型进行前、后处理分析,光学晶体组件采用六面体网格。由于结构比较复杂,选取三维20节点实体单元Solid95进行有限元分析,每个节点有三个自由度,此单元能够容许不规则形状,并且不会降低精确性,同时,其偏移形状的兼容性好,单元在空间的方位任意。

为防止部分网格奇异,同时减少计算量,将模型中非关键部件做适当的简化。机头的模态分析过程为线性的,在机头各部件之间采用“绑定”接触,即分析过程中,两接触表面假定一直是粘在一起的,由于没有接触收敛问题,求解更快。接触类单元采用CONTA174、TARGE170 并通过设置单元KEYOPT将其“bonded”。

-

通过模态分析可以得到机头结构和结构组件的振动特性,包括固有频率和相应的阵型,为保证计算的精度和速度,模态计算方法采用分块Lanczos法,调用稀疏矩阵方程求解器进行求解。

提取仿真结果所有的四阶模态,第一阶固有频率为178.236 Hz,最大振型幅值位于扩束器及扩束器上方外壳上;第二阶固有频率为567.278 Hz,最大振型幅值位于输入镜端外壳上;第三阶固有频率为932.786 Hz,最大振型幅值位于扩束器和扩束器上方外壳以及散热区底端;第四阶固有频率为1504.8 Hz,最大振型幅值位于机头前端散热区,其中,第一阶振型位移云如图2所示。

-

试验平台采用德国Polytec激光测振仪及电动振动台搭建,试验样品共有一件,外形为长方体,长×宽×高=310 mm×82 mm×180 mm,重约7.1 kg,底部3个M8螺栓固定,见图3。通过铝合金材料制作的过渡板固定在电动振动台上。利用振动台进行激振,结合模态仿真结果确定激振方向为样品的侧向,即图中标示(红色箭头)方向。测点布置共194个测点,测试过程中激光器处于关机状态。

此次试验分析带宽为2 kHz,谱线数为6400,频率分辨率为0.31 Hz。过滤低频噪声影响,试验的有效分析带宽为100~2 000 Hz。试验测试过程见图4,激光测振仪的某测点测试结果如图5所示。

-

试验测得各点频域振动速度信号,由PSV软件计算得到各测点相对于参考点的传递函数,并导出传递函数数据。利用LMS模态分析软件PolyMAX方法识别固有频率和振型。频响函数曲线及稳定图如图6所示,可见有4阶固有频率,振型的模态置信因子矩阵如图7所示,表明各振型相互正交,通过固有频率与振型拟合出理想的频响函数,与实测频响函数对比进一步验证结果。

此次试验测得2 000 Hz以内样品的四阶振型、固有频率与2.2小节中的仿真结果进行对比,见表1,可以看出,试验与仿真计算振型描述一致,固有频率误差较小(8%以内),从而验证了仿真模型的正确性,为进一步开展谐响应仿真分析奠定了基础,图8给出了试验与仿真分析的第一阶振型对比云图。

Order Natural frequency/Hz(Simulation) Natural frequency/Hz(Test) Mode description(Simulation,Test) 1 178.236 166.142 Top core area asymmetric side swing 2 567.278 480.670 Top core area side twist 3 932.786 873.262 Front second-order asymmetric side swing 4 1504.8 1473.912 Front heat dissipation area side swing Table 1. Natural frequency and vibration mode

-

中红外固体激光器的光学晶体组件位于激光器顶端并由盖板等密闭封装且由于光学晶体本身反射激光测振仪的光斑,因此其振动特性不适用于非接触试验测量。要获取光学晶体组件的谐响应分析结果,可利用有限元分析软件进行仿真并绘制位移对频率的曲线,从这些曲线上可以找到“峰值”响应,从而预测结构的持续动力特性。第3章通过激光器模态试验与仿真结果对比,已验证了仿真计算模型的正确性,模态分析是谐响应分析的基础和前提,因此通过仿真分析获取激光器光学晶体组件的谐响应是可行的。

根据固体激光器通用规范,激光器车载情况下的振动条件应不低于以下标准:正弦扫频振动,振动频率10~300 Hz,加速15 m/s2,振动方向:垂直轴向,一次扫描时间15 min,2个周期。

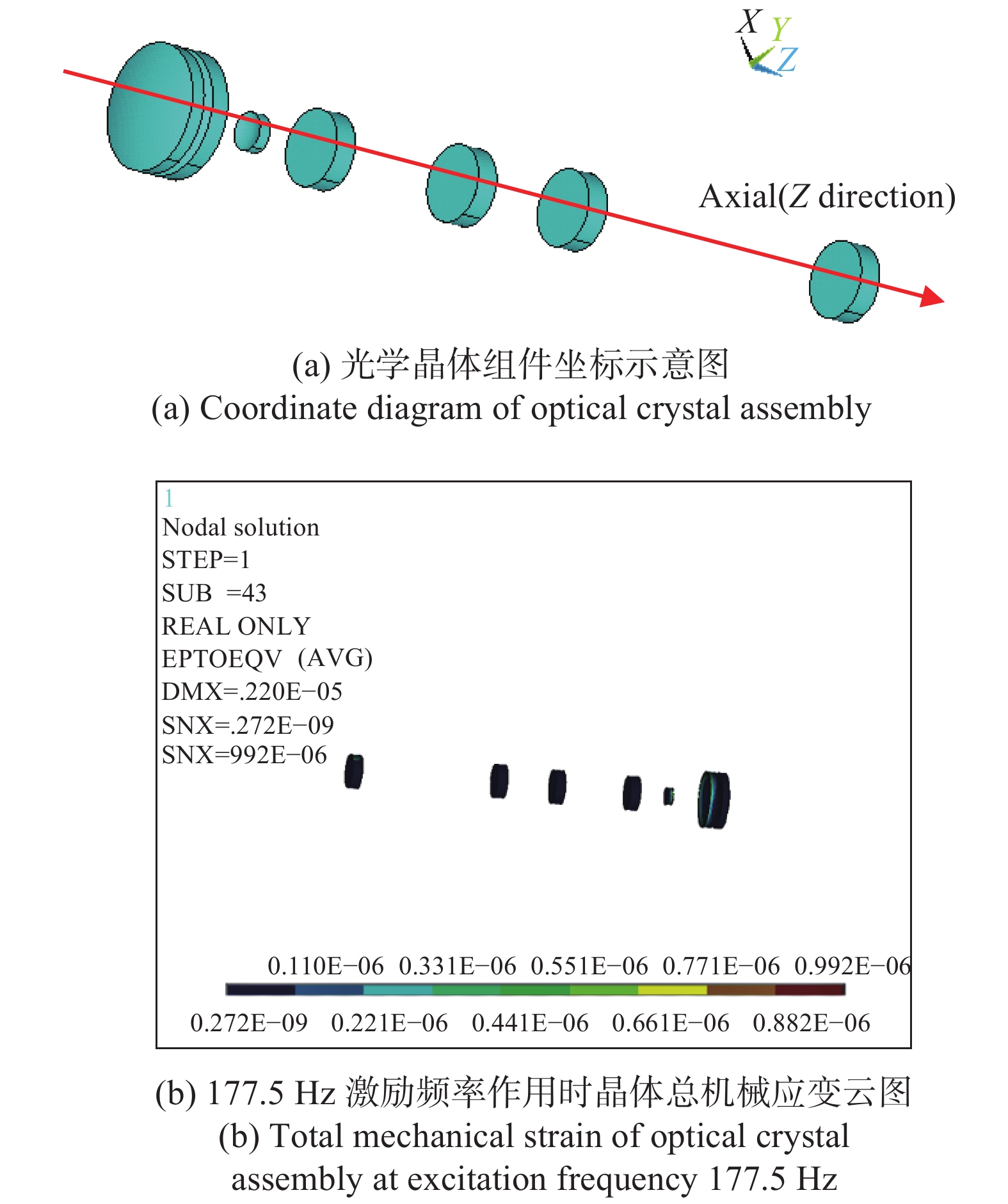

忽略阻尼的影响,对激光器施加垂直轴向(y方向,如图9(a)所示)的简谐振动激励,提取一阶固有频率附近(177.5 Hz)的计算结果,光学晶体组件总机械应变如图9(b)所示,考虑镜片组件工作时的稳定性,发现组件较大的应变主要集中在2 μm固体激光器的前、后腔镜、扩束器及扩束器输入镜上,最大总机械应变出现在扩束器的输入镜边缘。

Figure 9. Harmonic response of optical crystal assembly under the condition of vehicle frequency sweeping vibration

选取扩束器输入镜边缘上的结点,通过ANSYS时间-历程处理器提取结果,可以得到在其一阶固有频率附近,三个方向均出现位移频响的极值,其中,Z方向(见图10)极值最大,位移与激励频率的关系(横轴为激励频率,纵坐标为提取关键点处X、Y、Z方向位移,方向坐标见图9(a)),其中X方向最大位移约0.87×10−2 mm,Y方向最大位移约5.4×10−2 mm,Z方向最大位移约0.14 mm,即沿晶体的轴向出现的位移最大,最容易影响其工作时的精度。

-

通过有限元仿真与非接触激光测振相结合的方式得出了中红外固体激光器共有四阶固有频率与振型,试验与仿真计算振型描述一致,固有频率误差8%以内,验证了模态仿真模型的可靠性,在此基础上进行的谐响应分析表明,车载激光器核心光学晶体组件在其一阶固有频率附近产生较大的应力、应变,扩束器的输入镜边缘出现总机械应变和等效应力的极值,该位置最有可能影响到光路同轴,同时,车载扫频振动下沿晶体的轴向(Z方向)位移最大,晶体将更容易失稳,从而导致激光器输出功率的下降。

振动分析结果可预测固体激光器的持续动力特性,能够验证其设计能否成功地克服共振、疲劳及其他受迫振动引起的有害影响,对于评价中红外固体激光器的振动可靠性具有重要的指导意义,进而为结构优化和工艺改进提供支撑。

Vibration reliability of mid-infrared solid laser

doi: 10.3788/IRLA20200242

- Received Date: 2020-11-17

- Rev Recd Date: 2020-12-23

- Available Online: 2021-05-12

- Publish Date: 2021-04-30

-

Key words:

- vibration reliability /

- mid-infrared solid laser /

- non-contact vibration measurement technique /

- optical crystal assembly /

- simulation

Abstract: Based on ANSYS, finite element simulation calculation model of mid-infrared solid laser was established, and modal parameters, such as natural frequency and vibration mode were gained through modal analysis. Combined with non-contact vibration measurement technology, the vibration modal test platform was set up, and the reliability of the modal simulation model was verified by the comparison with the test. Then, on the basis of modal simulation, the vibration characteristics of laser optical crystal assembly was studied emphasisly under condition of sinusoidal frequency sweeping vibration of vehicle through response analysis, and equivalent stress, total mechanical strain, relation between displacement and excitation frequency can also be obtained. Last, the key positions that affecting the vibration reliability of laser were analyzed and the results provide useful reference for improving design. The results indicate that there are four natural frequencies and modes in middle infrared solid laser using bottom fixed constraint, within 2 000 Hz and the experimental results of the modal agree with simulation results, and the natural frequency error is less than 8%. The maximum total mechanical strain and equivalent stress appeared at the edge of the input mirror under the condition of vehicle frequency sweeping vibration. The axial displacement along the optical crystal assembly is the largest and its value is about 0.14 mm.

DownLoad:

DownLoad: