-

自苏格兰物理学家詹姆斯·杜瓦(James Dewar)发明了杜瓦瓶以来,其基本功能仍然是真空绝热。在红外技术领域,广泛采用杜瓦真空封装的结构形式,但真空绝热功能的长期保持问题突出,主要原因包括红外芯片的耐受温度不高,只能低温烘烤除气;红外芯片的封装中使用了有机粘接剂,出气量大;杜瓦真空绝热空间内要求高真空环境,要求苛刻。

在杜瓦制造中的排气过程及用户使用过程中,放气率显著影响杜瓦真空绝热空间内所能达到的压强,同时与抽速相关。杜瓦内压强的理论计算方法见公式(1):

式中:p为杜瓦内真空绝热空间内的压强,单位为Pa;Q为杜瓦放气率,单位为Pa·m3/s;S为抽气装置对杜瓦的有效抽速,单位为m3/s;Qi为第i类气体成分的放气率,单位为Pa·m3/s;

${A_j}$ 为第j个零件的表面积;Si为抽气装置对杜瓦内第i类气体成分的有效抽速,单位为m3/s;n为气体成分种类数;m为零件总数。受排气管流阻限制,杜瓦组件在排气过程中的有效抽速为2×10−5 m3/s,引起排气中杜瓦内的压强明显高于真空系统主腔室的压强,导致气体再吸附问题严重,制约杜瓦组件的排气效果。若使用0.3 m3/s的主抽气系统排气,并且忽略真空腔体的放气,杜瓦内压强与主室真空腔体内存在4个数量级的压强差。

放气率决定着杜瓦排气中所能达到的最小压强。若放气率降低1个数量级,杜瓦真空绝热空间内所能达到的压强降低1个数量级,能够弱化再吸附问题。另外,设计中尽量增加排气流导,降低放气率大造成杜瓦内压强过大。

-

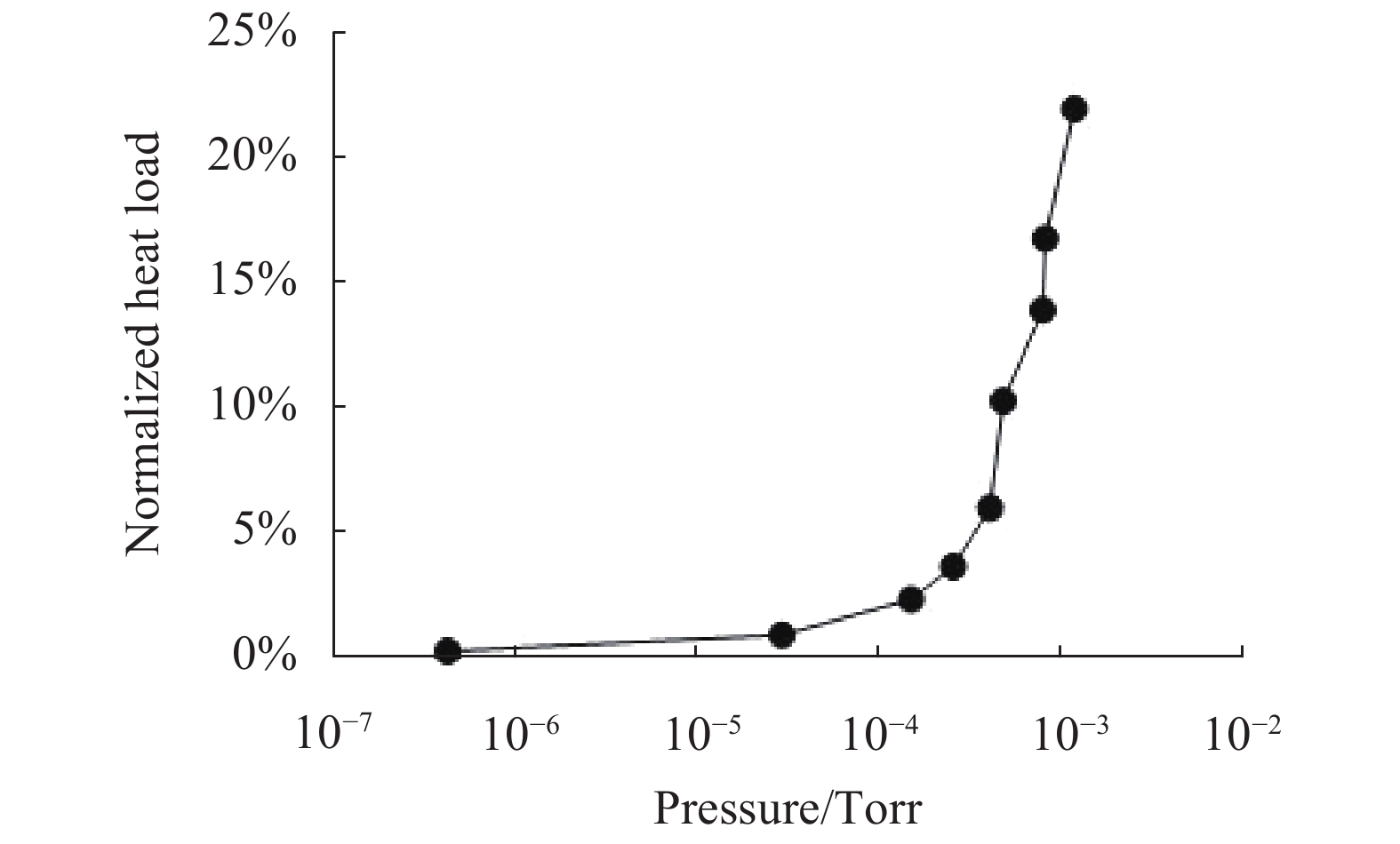

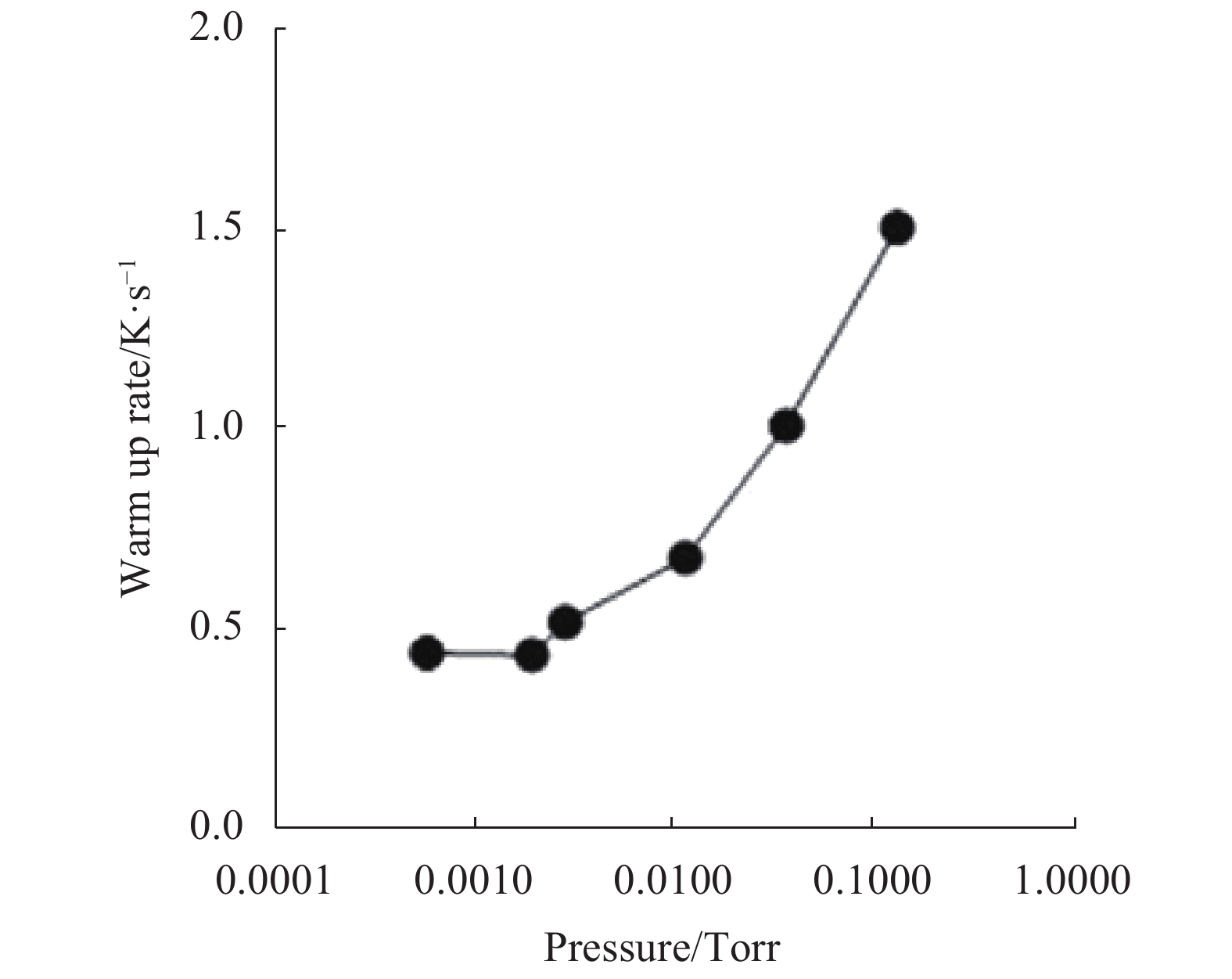

杜瓦丧失真空绝热功能的本质是内部气体分子增多后的压强升高,杜瓦内压强越大热负载越大,见图1[1](图中,1 Torr=133 Pa)。杜瓦热负载增加会导致制冷机高功耗和高频率工作,易造成制冷机故障,影响制冷机的可靠性,见图 2[2-3]。杜瓦真空度劣化导致红外探测器组件的制冷启动时间不达标,造成红外探测器组件的报废,见图 3。而引起杜瓦真空度劣化的主要原因是材料表面放气。

杜瓦组件的真空绝热空间内存在5类气体来源,包括空间气体分子、工艺气体干扰、漏气、逆流气体分子、放气,其中放气是影响杜瓦组件正常工作最重要的部分,并且放气源最难控制。

无论是杜瓦本身还是真空获得设备的漏气问题对真空保持最致命,极易导致早期失效。例如,某真空设备从大气状态抽至超高真空,气体成分随压强变化,超高真空状态下的主要气体成分为H2。设备的出气率处于1 E-9 Pa·m3/s,若存在同一出气率的漏孔,大气漏入系统后污染气体成分,存在较大比例的N2和O2。在受污染的真空设备上激活及使用吸气剂,导致吸气剂表面形成钝化层,影响吸气性能。

给定抽速的真空抽气系统,首先排除空间气体分子,压强服从指数

${{\rm e}^{ - kt}}$ 规律下降。随后受放气主导的抽气过程,服从${t^{ - n}}$ 规律下降,n在0.2~1.2之间变化。最后,压强受漏气和渗透的影响而保持不变,无法进一步降低,如图4所示。杜瓦组件内的气体源主要由表面吸附气体的解析放气、体扩散放气、渗透放气三类机理构成,遵从菲克扩散定理,气体分子由大气侧或材料内部流向真空绝热空间,见图5。

通过零件表面钝化处理,形成阻碍真空侧污染物的吸附、破坏大气侧气体分子渗透的阻挡层,阻碍气体分子扩散进入真空绝热空间,有助于降低放气速率。杜瓦壁制备钝化阻挡层的示意图见图6,杜瓦内表面形成致密的组织结构,抑制气体分子扩散。

文中采用表面镀钝化薄膜的方式控制杜瓦内的放气源,设计了杜瓦金属零件表面钝化技术方法。基于某型制冷型红外探测器杜瓦真空封装产品,实现杜瓦内壁钝化膜的制备,提供一种解决杜瓦真空长期保持高真空的有效途径。

-

制冷型红外探测器的杜瓦壳体包括多种金属零件,主要由杜瓦外壳、窗框座及内管零件构成,各零件为同心圆柱形结构[4]。表面钝化技术以优良的材料选择、表面清洁及光洁度处理为基础,再经过真空烘烤降低含气量。

选用恰当的材料来制备杜瓦是降低放气率的最简单方法。各种材料的放气率有显著差异,通常金属材料的放气率比环氧胶的放气率低一两个数量级。杜瓦选用的金属材料有比较低的放气率,以不锈钢、铜最为常用。另外,杜瓦材料的选用在机械特性、热特性、放气特性、成本等方面综合考虑。针对无法避免使用的粘接胶材料(环氧胶),严格控制用量及预处理条件。

清洁的零件表面是获得低放气率的基础,不同的清洗方法影响放气率[5]。杜瓦零部件遵照超高真空零部件的清洗要求,洁净的零件采用无油真空柜保存,防止二次污染。通常,越光洁的表面其放气速率越低 [5]。机械抛光能提高零件的表面光洁度,但对降低放气率不明显。通常采用电化学抛光获得极低的表面粗糙度,并结合真空烘烤降低放气率。气体辉光放电清洗可以获得原子级光洁的表面,能有效去除碳、氧。零件的高温真空预除气对降低杜瓦放气率有积极意义,通常采用高于100 ℃的烘烤温度去除大部分的H2O,在400~500 ℃烘烤几个小时主要用于去除材料体内的氢,更高的烘烤温度主要为了缩短除气时间。

文中实验选用杜瓦内常用的不锈钢、可伐零件,并通过激光焊接构成实验件。选用不锈钢、可伐零件构成管状薄壁结构,采用热的溶剂中超声洗、热的去离子热水冲洗,并经历真空中250 ℃烘烤除气处理后真空柜保存(暴露大气的时间控制在24 h内)。

-

针对不锈钢零件,采用电化学抛光后的表面钝化处理;针对不锈钢、可伐零件,可采用表面镀钝化薄膜阻挡层,常用PVD法制备表面钝化涂层,涂层厚度为0.1~10 μm (常用1 μm)。具备阻挡功能的涂层材料有多晶Si、TiN、BN、Al2O3、ZrO2。另外,针对不锈钢材料的钝化技术,常用大气中氧化处理形成Cr2O3 (大气中100~250 ℃烘烤2~5 h)。

常用的镀膜设备基于平面基片上沉积薄膜,无法在杜瓦内表面直接应用。设计了一种杜瓦内表面钝化处理的方案,见图7。采用的膜材为丝状的钛,直径为0.2 mm,并放置在圆柱形杜瓦外壳的中心位置,保证薄膜的均匀性。

将待镀的薄膜材料安装于杜瓦壳体的中心作为电极,杜瓦壳体采用压条紧固。采用蒸发法镀膜,控制镀膜参数完成钝化层的制备(真空度优于1 E-5 Pa,首先2 A 2 h的除气,再加电流3.5 A 2 h完成镀膜),镀膜完成后待工件冷却后关闭真空抽气系统,充入干燥的N2后取出工件。

-

通常杜瓦内没有配置真空规,可采用升温率法间接测试内部压强。升温率法由以色列SCD公司首创,其初衷是实现高工作温度点下杜瓦组件的热负载测试[6]。另外,采用升温率法能在线测试杜瓦的漏热,实现杜瓦内压强的评判。用户通过升温率的变化幅度即可实现保守型的真空维修方案,避免压强过高造成的制冷机故障[3]。基于某型杜瓦产品,采用升温率法测试了不同杜瓦内部压强下的升温率,验证了该方法的有效性,见图8。

文中实验为了更直观的对比改进效果,借鉴主流的放气率测试方法[7-24],采用压强上升法测试钝化处理前后的放气率变化。压强上升法即气体累积法,通过一定时间内的平均压强上升率来测试放气率,放气率的计算方法见公式(2):

式中:Q为杜瓦的总放气率;q为杜瓦单位面积的放气率;A为杜瓦的内表面积;dP/dt为压强上升率;P1为累积前压强;P2为累积终止时压强;V为测试室容积。

将钝化处理的杜瓦样品(见图9(a))、无处理的杜瓦样品(见图9(b)),分别进行低温烘烤过程下的放气率测试及气氛分析,测试结果见图9、和图10。结果表明,杜瓦封装用结构材料的主要气体成分为H2,内表面镀钝化膜后有效抑制了氢气的释放,放气率降低90%。

-

文中将丝状镀膜材料置于杜瓦封装结构的中央,完成了钝化层的制备,保证镀膜均匀性。镀膜时丝为电极的一端,真空室作为另一电极,通过蒸发法实现镀膜。

杜瓦结构中的不锈钢适合采用电化学抛光使表面的Cr富集,再经高温烧结去除体内氢含量,最终在表面形成致密的Cr2O3钝化层,单位面积的表面放气速率能达到2×10−15 Torr·L/(cm2·s)。杜瓦结构件中的可伐材料,采用表面镀膜的方式形成阻挡层,TiN、BN等硬质薄膜都能形成良好的钝化效果。为兼顾杜瓦零部件的制备过程,文中采用低成本的薄膜钝化阻挡层,杜瓦放气率从8.66×10−10 Pa·m3/s降低到8.4×10−11 Pa·m3/s,放气率降低一半以上,具备工程应用价值。

Effect of part surface passivation on Dewar outgassing rate

doi: 10.3788/IRLA20200321

- Received Date: 2020-09-03

- Rev Recd Date: 2020-10-25

- Publish Date: 2021-05-21

-

Key words:

- Dewar /

- vacuum insulation /

- cool down time /

- service life /

- surface treatment /

- passive film

Abstract: There are many gas sources in the Dewar’s vacuum insulation space, the biggest gas source is material outgassing. The problem of outgassing pollution caused by the desorption, volume diffusion, and penetration of the adsorbed gas on the inner surface of the vacuum insulated space of the refrigerated infrared focal plane detector Dewar component was focused, which affected the cool down time and restricted the service life of the infrared detector component. A passivation treatment plan for the inner surface of the infrared detector Dewar was designed, and the passivation film on the inner wall of the Dewar was prepared based on a certain type of Dewar product. The pressure rise method was used to compare the outgassing rate, and the gas composition was analyzed by a quadrupole mass spectrometer. The test results of outgassing rate show that the passivation film effectively inhibits the release of hydrogen, and the outgassing rate of Dewar is reduced by more than half. The processing method of the passivation film on the inner surface of the Dewar is simple and effective, which improves the vacuum life and has engineering promotion value.

DownLoad:

DownLoad: