HTML

-

红外相机已广泛应用于空间探测和对地观测各领域,为了提高红外探测器性能,其工作温度均处于100 K以下[1-3]。此时,影响红外相机探测灵敏度和空间分辨率的主要因素来源于系统内光学系统和光机结构产生的热辐射,只有降低光学系统的工作温度,减少背景光子通量,才能充分发挥探测器的作用[4-6]。因此,高性能的红外相机,采用低温光学系统成为红外探测技术发展的必然趋势。

1983年,美国成功发射红外天文卫星,通过液氮系统将光学系统冷却到4 K,自此低温光学技术在航天领域得到了迅速的发展。目前,低温光学技术已在欧美各国和日本发展相对成熟,并已成功应用于红外天文观测、精细对地观测等领域[7-9]。回顾国外低温光学发展史可以看出:运行轨道由近地轨道向远地轨道发展,光学系统口径朝着大口径方向发展,制冷方式由储存式制冷向机械制冷和辐射制冷复合制冷的方向发展。近年来,随着国内红外探测技术的发展,对低温光学系统的需求愈加浓烈,各科研单位及大学相继开展了相关方面的研究。马宁[10]等人对低温光学关键技术进行了综合性研究分析;王兆利[11]等人通过搭建试验台,对一种透射式低温光学系统的光机结构热设计进行了研究,王洪亮[12]等人通过仿真分析,对运行于拉格朗日轨道的望远镜遮光罩进行了设计分析。虽然低温光学研究在国内取得了长足的进展,但相比于国外成熟的低温光学技术,国内仍处于萌芽阶段,特别是在低温区甚至深低温区的型号应用经验比较缺乏。

某红外相机光学系统为透射式全光路冷却系统,通过杂光分析手段,按照光机背景辐射小于探测背景辐射的十分之一,整机的探测信噪比可以满足要求,通过分析确定相机低温光学系统的温控指标,其光学透镜温度水平、温度梯度及温度稳定性对红外探测器的成像质量起着至关重要的作用。文中基于辐射制冷技术、间接辐射控温技术、高效热防护技术、高效热隔离技术及低温热传输技术对红外相机光学系统进行了热设计,并对热设计进行了热平衡试验验证。

-

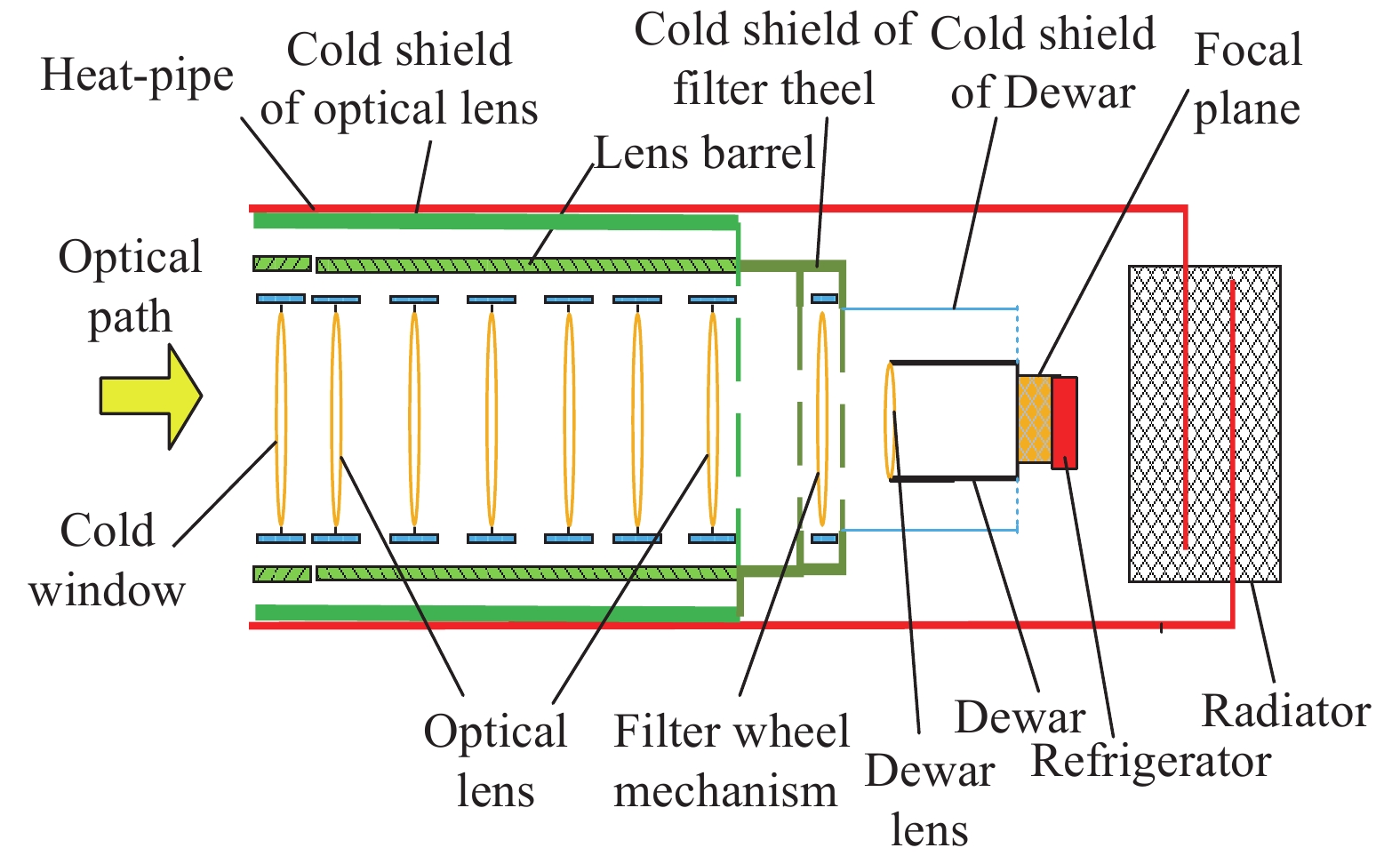

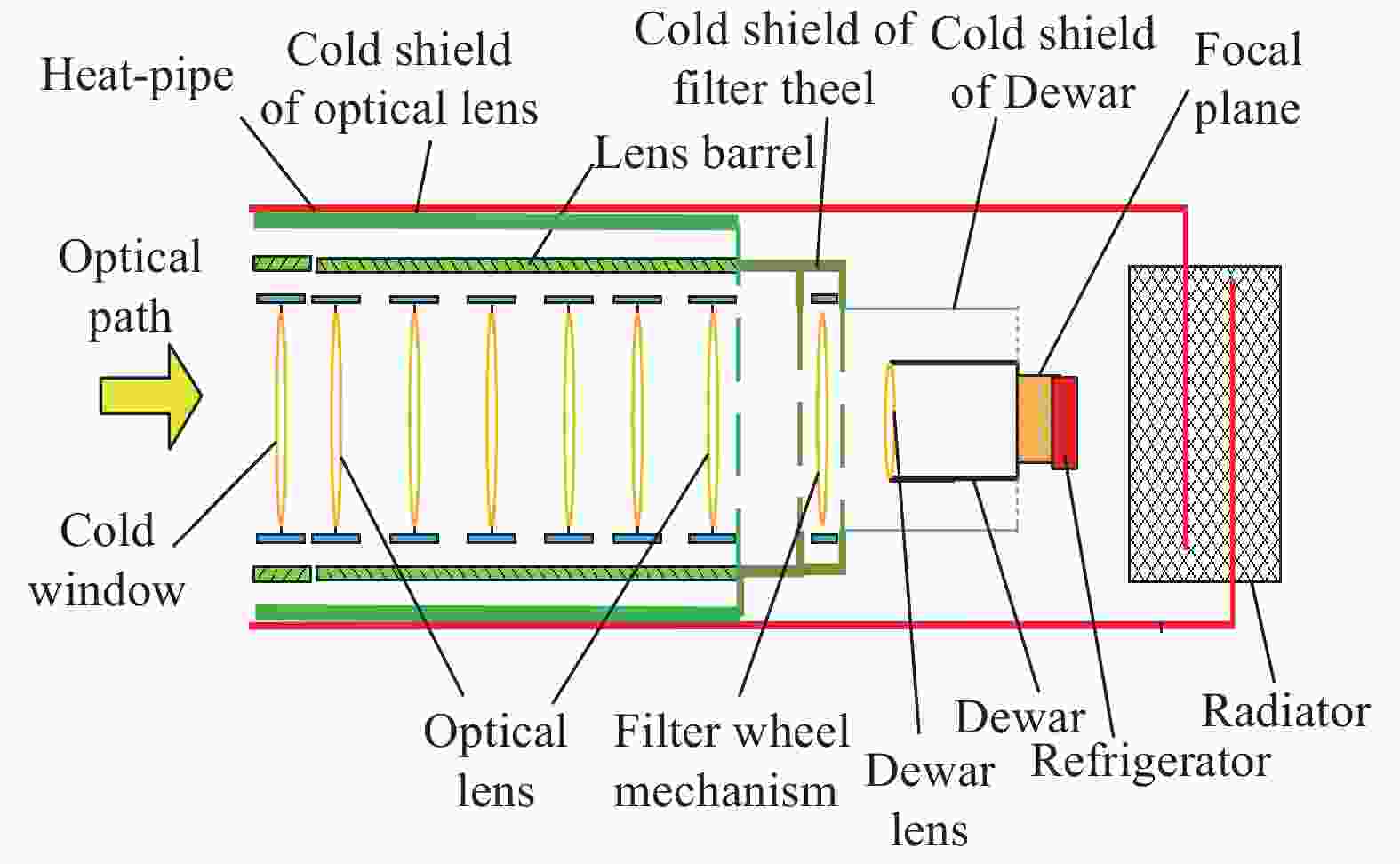

红外相机通过支撑结构安装于相机底板,主要由遮光罩组件、冷窗组件、低温镜头组件、滤光轮组件、探测器焦面、制冷机组件、承力结构、电路盒等组成,相机结构布局示意图如图1所示,主要部组件温度指标见表1。

Components Temperature requirement/K Image case Decontamination case Cold shield 210±5 313±5 Optical lens 210±5,axial temperature difference less than 5,temperature fluctuation less than ±0.5 313±5 Filter 210±5,temperature fluctuation less than ±0.5 313±5 Lens of Dewar Less than 235,temperature fluctuation less than ±0.4 313±3 Table 1. Temperature demands of the camera

-

红外相机光学系统为全光路低温光学系统,所处空间热环境复杂多变,热控难度大,主要表现在以下方面:

(1)光学透镜系统由直径为317~427 mm的6片透镜组成,通过镜框安装于镜筒上,并通过支撑结构安装于相机地板上。镜筒直接为485 mm,长度约950 mm,其前后两端均为光路开口,无法形成封闭的“热保护”系统,其体积庞大,辐射漏热量大。受光学系统周围常温结构的影响,如何降低光学系统辐射漏热及降低光学镜头轴向温差和温度稳定性是系统设计关键所在;

(2)镜头组件为低温光学系统,其安装边界及周围部组件均为常温设备,相机高效隔热设计难度较大;

(3)相机位于倾斜地球同步轨道,无长期背阴面,低温光学系统散热设计难度大。

-

为满足红外相机低温光学系统全光路冷链温度要求,采用了辐射制冷技术、间接辐射控温技术、高效热防护技术、高效热隔离技术及低温热传输技术,其热控总体方案如下:(1)光学系统制冷:为了实现低温光学系统低温需求,采用辐射冷屏对光学镜头进行热量收集,并通过低温热管将光学系统的热量传递至散热器,最终通过辐射制冷进行散热;(2)高效热防护:通过卫星姿态调整及辐射冷屏设计,减小空间辐射及光学系统周围高温结构向低温光学系统辐射漏热;(3)高效热隔离:采用Bipod杆支撑、迂回式支撑、隔热垫、低导热率材料等措施减小导热漏热;(4)主动控温设计:为提高低温光学系统温度稳定性及加热去污需求,合理设计主动控温加热回路。控温措施如下。

-

相机光学系统包括冷窗透镜、光学透镜、滤光片和杜瓦透镜,为全光路低温光学系统,对制冷温度、轴向温差及温度稳定性提出了较高的要求。针对其控温需求及相机特点,采用全光路冷屏间接辐射控温方式,利用低温热传输热控产品,最终通过散热器辐射制冷的方式实现镜头的降温。光学系统制冷设计示意图如图2所示,具体热控措施如下:

(1)光学系统外布置冷屏结构,通过冷屏结构对低温光学系统间接辐射控温,从而提高低温光学系统温度均匀性和稳定性;沿冷屏轴向安装两根热管,热管另一端与镜头散热器相连,通过散热器辐射制冷。

(2)冷屏分三段,分别为光学镜头冷屏、滤光轮冷屏及杜瓦冷屏,各冷屏间导热安装,内表面黑色阳极化以增强冷屏与各透镜间换热,外壁包覆多层隔热组件以减小漏热。

(3)冷屏安装于镜筒上,并与支撑结构隔热安装,具体措施见下文。

(4)镜头散热器布置于机-X侧,并与支撑结构通过聚酰亚胺隔热垫隔热安装,外侧喷涂ACR-1防静电热控涂层以提高散热器散热性能。

(5)光学系统设置主动控温加热回路,以提高其控温精度,同时可用于光学镜头加热去污,具体措施见下文。

(6)杜瓦结构采用导热性能较差的钛合金材料,厚度为2 mm,安装在制冷机热端支撑板上,通过杜瓦冷屏对杜瓦结构进行低温制冷,实现其低温需求。焦面探测器通过制冷机进行深度制冷,制冷机总热耗约80 W,通过氨工质槽道热管进行热量传递,最终通过制冷机散热器进行辐射散热。

为了保证光学系统通过辐射制冷顺利达到控温指标,需要对全光路系统漏热量进行精确计算,以设计适当散热器面积辐射制冷。由能量守恒方程得:

式中:A为散热器面积,m2;

$\varepsilon $ 为散热器热控涂层发射率;$\sigma $ 为玻耳兹曼常数,W/(m2·K4);T0为散热器温度,K;Q散为散热器散热量,即周围环境向光学系统漏热量;Q多层为多层漏热量;Q支撑为支撑漏热量;Q入光口为相机入光口辐射漏热量。其中

式中:

${\varepsilon _{{\rm{eff}}}}$ 为多层有效发射率;A多为多层面积,m2;Th、Tl、Tj分别为环境温度、冷屏温度和镜筒温度,K;S为冷屏、镜筒之间辐射换热面积,m2;Eb1、Eb2为镜筒、冷屏辐射力,W/m2;R、R1、R2分别为支撑热阻,热管与冷屏接触热阻、热管与散热器接触热阻; $\Delta {{T}}$ 为热管两端温差。由公式(1)~(5)分析计算得低温光学系统散热器面积A为0.28 m2,经过仿真分析迭代,最终确定散热器面积为0.3 m2。

-

红外相机运行于倾斜地球同步轨道,轨道外热流复杂多变,通过卫星姿态规避及外遮光罩设计实现相机入光口和-X侧全轨内外热流为0。卫星姿态规避策略如下,遮光罩及散热器布局示意图如图3所示。

(1)为实现相机-X侧始终背阴:在地方时正午、午夜前后,均有偏航180°的机动,即地方时“午夜-正午”弧段+X轴为飞行方向,“正午-午夜”弧段-X轴为飞行方向;

(2)为避免光线直射相机遮光罩内壁,制定阳光规避策略:在午夜前后,当阳光与+Z轴夹角小于25°时,整星姿态偏置,确保+X面受照且该角度大于25°;

(3)当有阳光规避弧段时,规避姿态需与午夜偏航180°的动作结合起来执行,即规避动作前后的±X指向互换。

根据上述姿态规避原则及外遮光罩遮挡设计,通过卫星总体提供卫星在轨一年内RPY角,经过热仿真外热流分析,卫星的-X侧为长期背阴面,相机内遮光罩的内外壁均不受照,相机的外遮光罩内壁不受罩,相机入光口外热流始终为0。

-

为缓解镜头制冷器辐射制冷压力以及周围环境对低温光学系统的干扰,需对支撑结构进行高效热隔离设计,以减小周围环境向光学系统漏热,支撑结构示意图如图4所示,具体隔热措施如下。

(1)相机底板到光学系统之间采用两级Bipod支撑杆设计以增加导热热阻,支撑结构外包覆多层隔热组件;

(2)相机底板到焦面之间采用迂回式支撑以增加导热热阻,支撑结构外包覆多层隔热组件;

(3)支撑结构间及支撑结构与镜筒、脚面组件间增加聚酰亚胺隔热垫;

(4)相机底板及各电单机分别做273、263 K低温设计,减小向光学系统漏热。

-

主动控温主要用于解决航天器上对温度有严格要求的设备热设计上,是一种将被控对象温度控制在温度指标内的主动热控制技术。温度控制器将温度传感器反馈的被控对象的实时温度数据与温度指标进行对比处理,并对被控对象上的加热回路进行通或者断的控制,使被控对象进行加热补偿或不加热,以达到温度场控制的目的[13]。

为了提高光学系统控温精度及满足光学镜头加热去污需求,在光学系统各部组件上设置了主动控温加热回路。如图5所示,主动控温系统由被控对象、电源、电加热器、温度传感器及控制器组成,在冷屏、镜筒、冷窗、滤光轮及杜瓦外壳上粘贴聚酰亚胺薄膜电加热器及热敏电阻温度传感器,通过热敏电阻温度传感器对控温对象实时温度数据反馈到温度控制器,最后由温度控制器通过温度数据判读对聚酰亚胺薄膜电加热器进行通/断状态控制,从而实现对各部组件的精确控温。针对不同工作模式对温度的不同需求,对各工作模式下控温阈值进行了精细设定,各加热回路位置及控温状态见表2。

Components Power/W Threshold/K Image case Decontamination case Cold shield 60 205±0.3 313±0.3 Lens barrel 40 210±0.3 313±0.3 Cold window 20 210±0.3 315±0.3 Filter 20 210±0.3 313±0.3 Dewar 20 210±0.3 313±0.3 Table 2. Statistics of heating circuit

1.1. 相机概述及控温指标

1.2. 相机热设计任务分析

1.3. 热设计方案

1.3.1. 光学系统制冷

1.3.2. 高效热防护

1.3.3. 高效热隔离

1.3.4. 主动控温设计

-

为了验证红外相机低温光学系统热设计的正确性和合理性,对相机模型进行了适当的简化利用Thermal Desktoop软件建立了热分析模型。热仿真建模过程中对于干接触表面间接触传热系数取300 W/(m2·K),对涂抹导热填料表面间传热系数取1000 W/(m2·K)。成像模式的选取原则:红外相机位于载荷舱外,外壁包覆20单元多层隔热组件,低温光学系统安装底板控温273 K,且在高效热防护措施下,入光口及-X侧散热面外热流为0,其热边界处于稳定的热环境条件下,为相机正常成像模式,各主动控温加热回路按照成像模式加载控温阈值,分析该状态下低温光学镜头制冷能力。加热去污模式的选取原则:加热去污模式下,低温光学系统控温313 K,为相机入轨前期加热去污状态,各主动控温加热回路按照加热去污状态加载控温阈值,分析该状态下低温光学系统加热去污能力。热仿真工况安排见表3。

Case Orbit heat flux The state of thermal control Temperature boundary of satellite/K Image case Maximum heat flux throughout the life cycle Image model 273 Heat decontamination case Minimum heat flux throughout the life cycle Decontamination model 273 Table 3. Operating conditions of test

-

为了验证热设计合理性及热控产品性能,在相机发射前需要进行充分的地面验证。真空低温下的热平衡试验通过在轨热环境及热边界模拟,获得的温度数据可以真实地反映相机在轨温度情况,对相机在轨稳定运行提供数据支撑。针对红外相机在轨工作模式对热设计性能需求,需重点考虑成像模式下低温光学系统制冷能力及加热去污模式下对光学镜头的加热能力。因此,试验工况设置了成像模式工况和加热去污模式工况,如表3所示。热平衡试验中,相机各部组件按照设计状态进行热控实施和总装,利用电加热器模拟相机在轨外热流,通过对试验工装控温模拟相机在轨热边界,试验过程合理有效,试验结果真实可靠。

-

图6给出了成像模式工况和加热去污模式工况全光路光学系统透镜连续三轨的热仿真温度曲线。图7给出了成像模式工况和加热去污模式工况全光路光学系统透镜连续三轨的热试验温度曲线,表4对各部组件热试验温度及热控平均功耗进行了汇总。由热仿真及热试验结果可知:

Figure 6. Temperature curves of lenses under thermal simulation image and decontamination case condition

Components Temperature/K Average power/W Image case Decontamination case Image case Decontamination case Cold shield 202.8-205.3 310.7-313.8 0 19.2 Lens barrel 210.1-212.4 312.1-315.1 4.3 14.1 Optical lens 210.3-211.3 311.8-313.2 − − Cold window 210.3 311.5 0 7 Filter 210.9-211.1 310.9 7.1 9.2 Lens of Dewar 225.9-226.4 312.7 0 4.2 Radiator 192.8-193.4 240-240.5 − − Table 4. Summary of test results

(1)热仿真数据与热试验数据温结果显示,光学透镜、冷窗透镜及滤光片温度均满足相机各工作模式下温度指标,验证了低温光学系统全光路低温热设计合理可行和低温光学系统加热去污主动控温加热回路布局合理可行。热仿真与热试验数据温差较小,热仿真模型准确可靠,热试验方案合理可行。

(2)相机全寿命周期内,全光路光学系统透镜温度波动均小于±0.3 K,光学透镜轴向温差小于1 K,满足成像模式下对光学镜头温度均匀性和稳定性的要求。全光路光学系统温度具有较高的温度均匀性和稳定性主要归功于三点:一是采用卫星姿态规避及外遮光罩遮光等高效热防护措施,有效地规避了复杂的空间外热流对相机入光口和散热器的影响,使相机处于舒适的空间热环境;二是采用了两级Bipod杆支撑、迂回支撑及低导热率材料连接等高效隔热措施,有效降低了周围常温区设备温度波动对低温光学系统温度的影响;三是采用全光路冷屏设计对光学系统间接辐射控温,有效提高了低温光学系统的控温精度[14-15]。

(3)由表4可知,成像模式下,镜筒和滤光片主动控温加热回路热控平均功耗约为11.4 W,由于采用高效热防护及高效热隔离技术,低温光学系统受外热流及周围设备温度波动较小,其热补偿功耗波动较小,相当于瞬态热补偿功耗。说明镜头散热器具有11.4 W散热能力的余量,或者具备进一步降低镜头温度的能力,验证了相机低温光学系统热设计的可靠性。

(4)由表4可知,加热去污模式下,镜筒温度约为313 K,散热器温度约为240 K,主动控温加热回路总补偿功耗为53.7 W,忽略加热去污模式下光学系统向周围常温设备漏热,由热管并列传热关系计算可得低温热管热阻约为2.7 K/W,远高于热管启动时的热阻。低温镜头热管为乙烷工质槽道热管,其最佳使用温度范围为170~230 K,在加热去污模式下,热管温度约为313 K,此时,热管内乙烷工质由汽液两相态变为气体单相态,热管无法依靠气化潜热换热,其传热热阻增加,起到了“热开关”的作用,降低了相机光学系统加热去污所需热控功耗。

2.1. 热仿真

2.2. 试验方案

2.3. 结果分析

-

针对红外相机内外部复杂的热环境及低温光学系统高精度控温需求,文中详细分析了相机热控设计的重点和难点,并基于辐射制冷技术、间接辐射控温技术、高效热防护技术、高效热隔离技术及低温热传输技术等一系列低温热控制技术,成功实现了低温光学系统全光路冷链热设计。热平衡试验结果证明:成像模式下,光学透镜、冷窗透镜及滤光片温度满足(210±5) K温度指标,杜瓦透镜满足小于235 K温度要求,光学透镜轴向温差满足小于5 K需求,各透镜温度波动全寿命周期内均小于±0.3 K;加热去污模式下,全光路光学系统透镜温度满足(313±5) K温度要求,且由于低温热管在常温下起到“热开关”作用,其冷热两端热阻高达2.7 K/W,低温光学系统所需热补偿功耗仅为53.7 W。

光学系统热设计突破了透射式红外相机全光路低温光学冷链设计,其热平衡试验结果验证低温光学系统热设计的正确性和有效性,同时为未来低温光学系统乃至深低温光学系统的设计及试验验证提供了宝贵的经验和有力的技术支撑。

DownLoad:

DownLoad: