HTML

-

随着航天飞行技术的发展,飞行器外形结构日益复杂、飞行空域日益扩大,高空飞行时间大幅度增加,稀薄气流区的气动问题日益突出。虽然飞行器在稀薄气流区的气动热载荷比稠密大气层内低,但大气的作用依然显著,且飞行器周围气体的流动特性与连续流有了显著差异。非弹道、高可控、长时间飞行的新型高超声速飞行器发展,对稀薄气流区的气动热载荷的精细预测提出迫切需求[1]。

在高高空地面试验中,有时通过热电偶等测量模型表面单点的温度,从而由温度梯度计算出表面热流。这类接触式测量技术发展历史较长,属于经典测量的一类。

红外热图作为非接触测量技术,形象直观,不干扰流场,一次试验可以获得成千上万个点的热流数据。作为气动试验的诊断工具,红外热图技术已广泛用于瞬态温度测量、旋涡捕捉、边界层转捩位置判断、分离流和层流的判定等。法国的SESSIA研究所的Jean Allegre等将红外热图技术用来测量稀薄气流中厚0.5 mm的平板模型表面的热流率[2],M.F.Westby在低密度风洞中,用红外热图技术确定平板模型与一系列细长锥模型表面热流率,并与其它结果进行了比较[3]。李明等将红外热图测热技术应用于一系列模型从近连续流到稀薄过渡流气动热特性研究[4]。毛羽丰等人针对各种复杂、极端热环境下的表面热流密度测量难题,提出了一种基于红外热成像技术的表面热流密度分布测量方法[5]。此外,耿子海等在翼型的气动特性设计过程中,使用红外成像非接触测量技术在大型低速风洞中测试了OA309旋翼翼型的自由转捩位置[6]。

在稀薄气动热地面试验研究方面,具有以下几个特点:一是模型表面热流低,从量值上看,其值为几kW/m2到几百kW/m2。量值小,导致各种因素的干扰影响相对变大,这种小参数、高精度测量比较棘手。二是试验模型小。为了模拟高空环境,采用的地面试验模拟准则要求把试验模型做得比较小[1],测量这种小模型头部、局部干扰区、连接部位的热流存在一定难度,需要采用薄壁量热法、红外热图等多种测量手段。三是模型加热时间对热流测量结果影响比较大,如何确定模型加热时间需要考虑多方面因素。

针对这些问题,文中首先从满足模型壁面定常热流假设和一维半无限大假设条件等五个方面,分析模型加热时间对热流测量结果的影响;其次采用多种方法,提高模型材料表面发射率测量精度,运用瞬变平面热源法,解决过去模型材料的热物性参数标定误差大的问题。最后对稀薄流地面试验特有的采用薄壁量热法获得的模型外壁面热流、内壁面热流和红外热图方法测量结果进行了比较。文中的试验是在Φ0.3 m高超声速低密度风洞进行的,该风洞模拟高度为30~90 km,可使用的喷管有M5-M12、M16、M24,前室总温在300~1700 K范围内可调。试验介质为氮气,喷管出口截面直径为300 mm。

-

在风洞试验时,通过红外热图技术测量非金属模型表面瞬态温度Tw,求解一维瞬态热传导方程时,如果模型表面热流为常数,那么可得:

式中:Tw为模型表面温度,单位是K;Ti为模型表面初始温度,单位是K;Taw为绝热温度,单位是K。当公式(1)左边各项已知时,便可求出β值,从而得到模型表面对流换热系数h,即:

式中:h为模型表面对流换热系数,单位是W/(m2·K);t为模型加热时间,单位是s;k、ρ、c分别为模型材料热传导系数、密度和比热容,其中模型材料热传导系数,单位是W/(m·K),模型材料密度,单位是kg/m3;模型材料比热容,单位是J/(kg·K)。从公式(2)可知,模型表面对流换热系数h是模型加热时间t的函数,如何确定模型加热时间,需要考虑多方面因素。

-

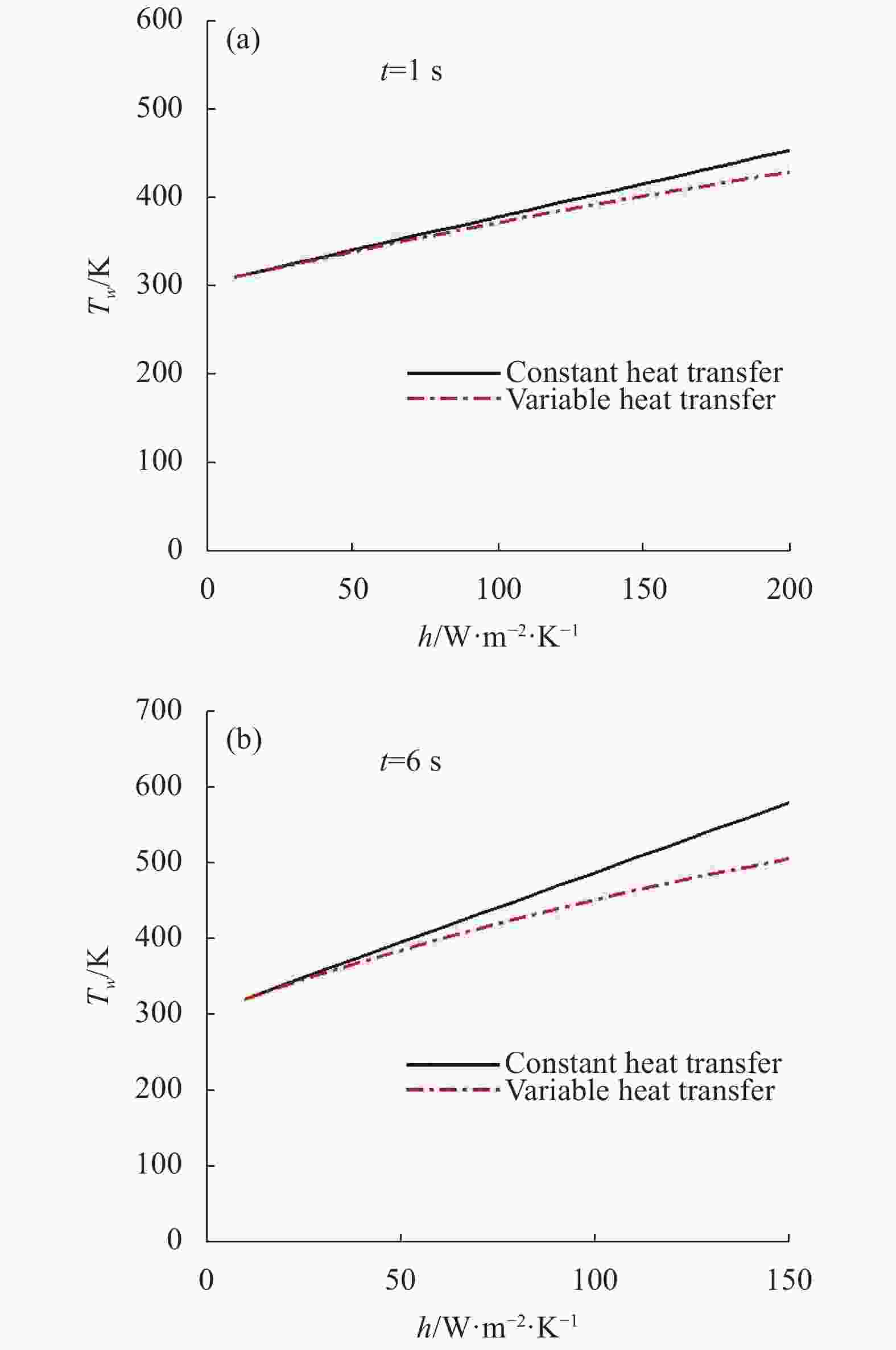

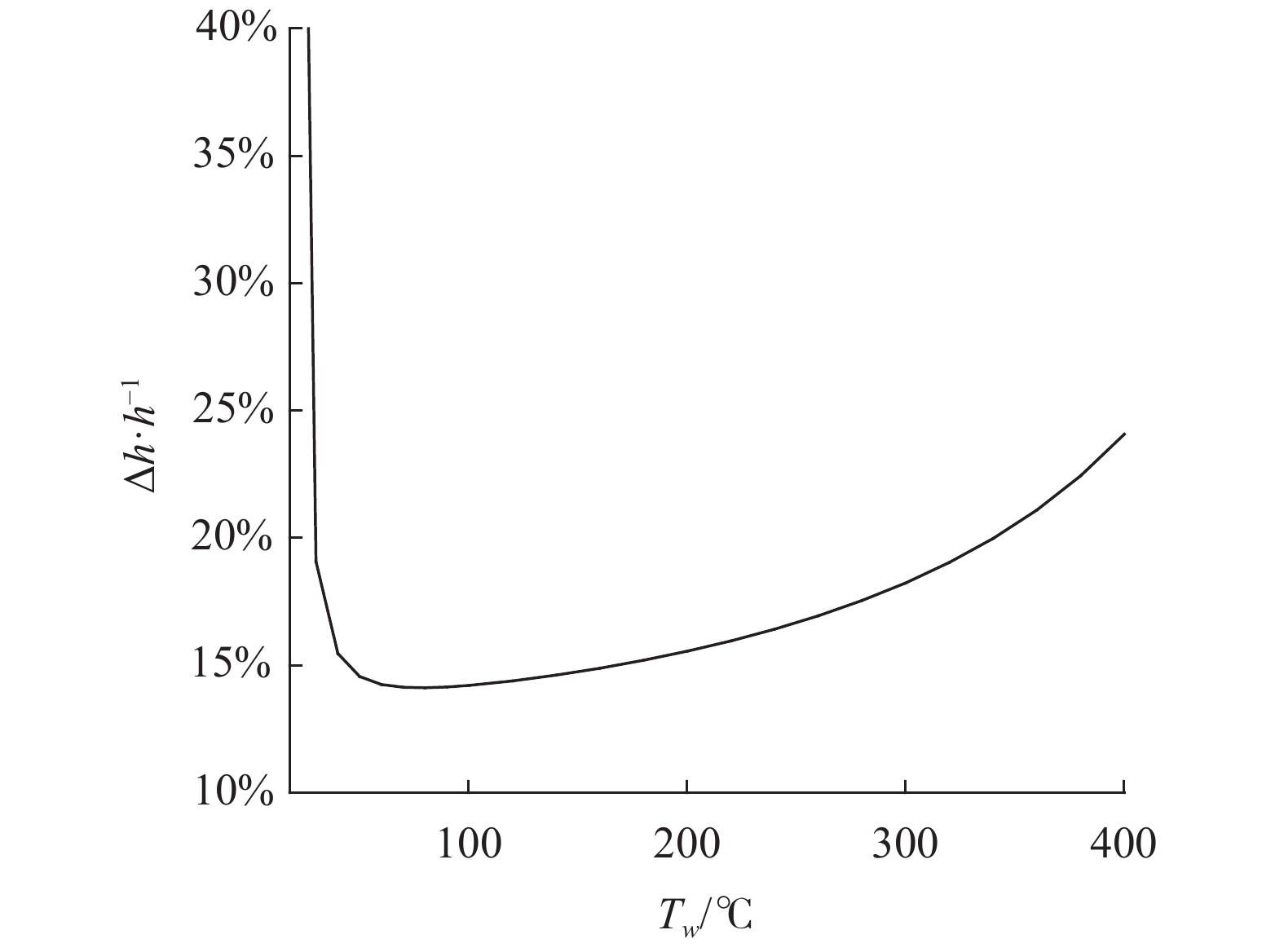

在求解一维瞬态热传导方程时,常常假设模型表面热流为常数。那么,在什么条件下模型表面热流为常数这个假设成立呢?采用隐式差分格式,求解一维瞬态热传导方程,通过改变模型表面对流换热系数,比较模型表面温差。对目前稀薄流地面试验所测量的热流量值来看,模型表面对流换热系数的范围一般为1~150 W/(m2·K),取模型加热时间为1~6 s。所获得的结果如图1所示。从图中可以看出,模型加热时间越短,壁面定常热流假设的近似性越好;模型表面对流换热系数越低,壁面定常热流假设的近似性越好。

-

在热流测量中,常常采用一维半无限大假设。如果模型在自由流中的加热时间满足

一维半无限大假设成立。式中:b为模型壁厚,单位是m;α为热扩散系数,单位是m2/s。对试验使用的厚0.5 mm不锈钢薄壁模型材料,其热扩散系数为4.9 mm2/s,由公式(3)确定的试验时间要小于0.01 s,这在风洞试验中很难实现;对试验采用的某种环氧树脂绝热模型材料,其热扩散系数为2.79×e−7 m2/s,该模型控制舵处最薄,为4.5 mm,对应的模型加热时间应该小于14.52 s。

-

Srtarner研究了半球圆柱驻点热流的侧向导热误差[7-9]:

式中:Ec是侧向导热热流与入射热流的比值;t是模型加热时间,单位是s;D是半球圆柱模型的直径,单位是m;k是导热系数,单位是W/(m·K);ρ是薄壁材料密度,单位是kg/m3;c是比热容,单位是J/(kg·K)。

根据公式(4),侧向导热误差并不是热流的函数,只与模型材料热物性参数、半球圆柱体直径和模型加热时间有关。由于侧向传热误差与模型加热时间成正比,所以模型加热时间不能取得太长。

-

在推算模型表面热流时,常常假设模型为一维半无限介质,实际上模型厚度不可能为半无限大,那么模型壁厚在什么条件下才满足一维半无限假设呢?考虑模型热渗透厚度z,它表示在时刻t模型内部热传导为零的最小深度。如果表面热流为阶跃函数,通过对一维瞬态热传导方程作LAPLACE反变换,可得

式中:t是模型加热时间,单位是s;α为热扩散系数,单位是m2/s。当满足公式(5)时,模型表面温度、表面热流的测量误差不超过百分之一。试验中常把公式(5)作为模型壁厚选取的准则。对热扩散系数为2.79×e−7m2/s的某种环氧树脂绝热模型材料,如果试验加热时间取1 s,模型表面热渗透深度为2 mm左右;如果试验加热时间取2 s,热渗透深度为3 mm左右。

-

在公式(1)中,通过对流换热系数h对Tw、Taw、Ti、(ρck)1/2、t这五个参数求偏导数,并使用误差传递的泰勒级数法,可得对流换热系数随机不确定度为[10]:

式中:Δh为h的绝对不确定度;ΔPi为五个参数Pi的绝对不确定度。

把这五个偏导数求出后,代入公式(1),经过整理,可得对流换热系数的随机不确定度为:

其中,

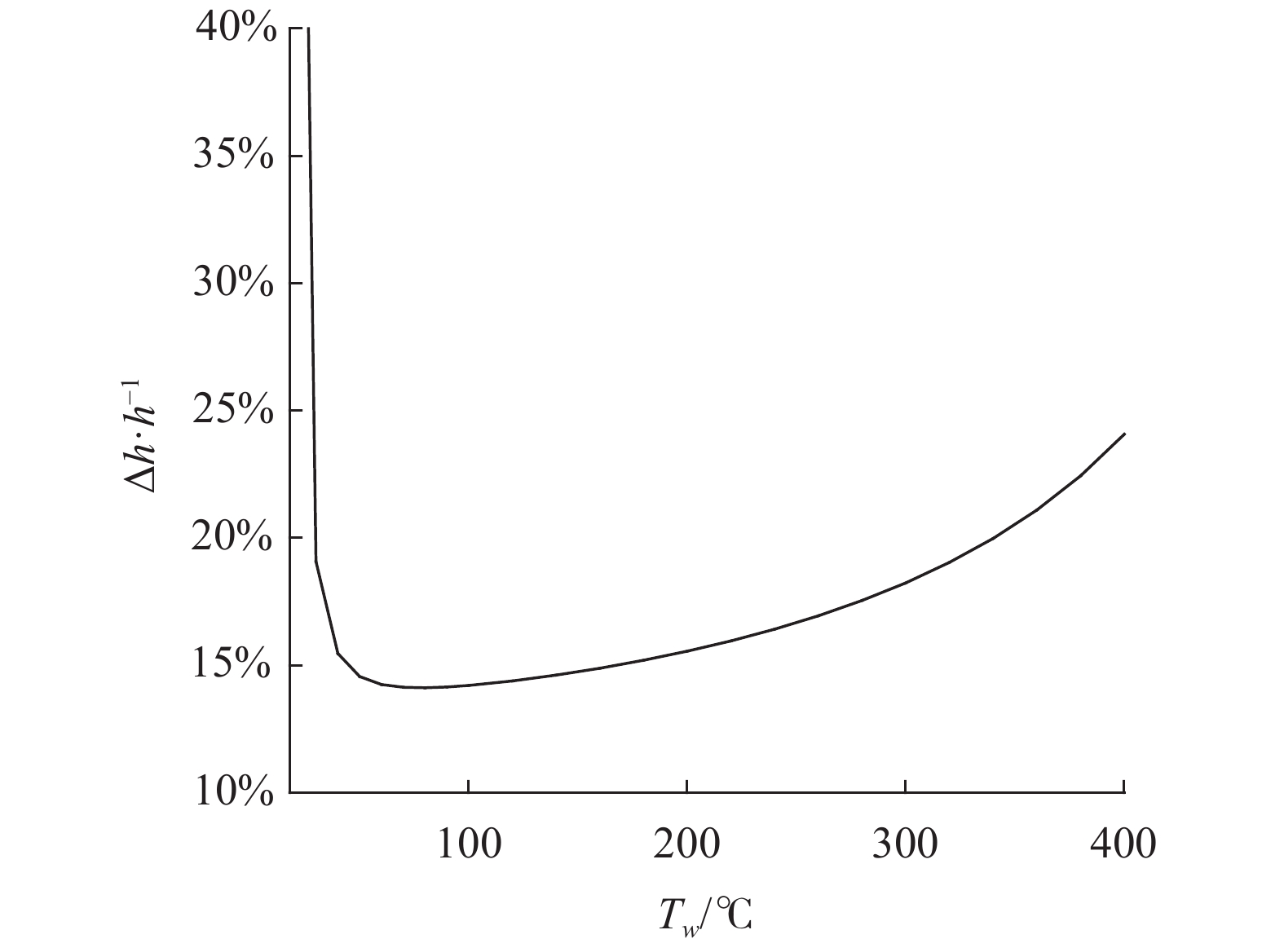

由公式(7)可以看出,在一定的试验条件下,对流换热系数的随机不确定度是模型表面温度的函数。在马赫数17.44、总温962 K、总压1.577 MPa、攻角30°的试验条件下,某升力体模型对流换热系数不确定度与模型表面温度的关系如图2所示[11]。从图中可以看出,对流换热系数测量误差是随模型表面温度变化的,在超出40~200 ℃温度范围时,测量的对流换热系数具有较大的误差。而对于给定的试验条件和选定的模型材料,模型表面温度主要取决于模型加热时间。因此合理选择模型加热时间,控制模型表面温升在一定范围内,可提高红外热图测量精度。文中使用的红外热像仪工作波段为2.5~5.1 μm,采用碲镉汞探测器,测温范围为5~500 ℃,帧频为5~115 Hz,灰度分辨率为14 bit,图像分辨率为640×512。

-

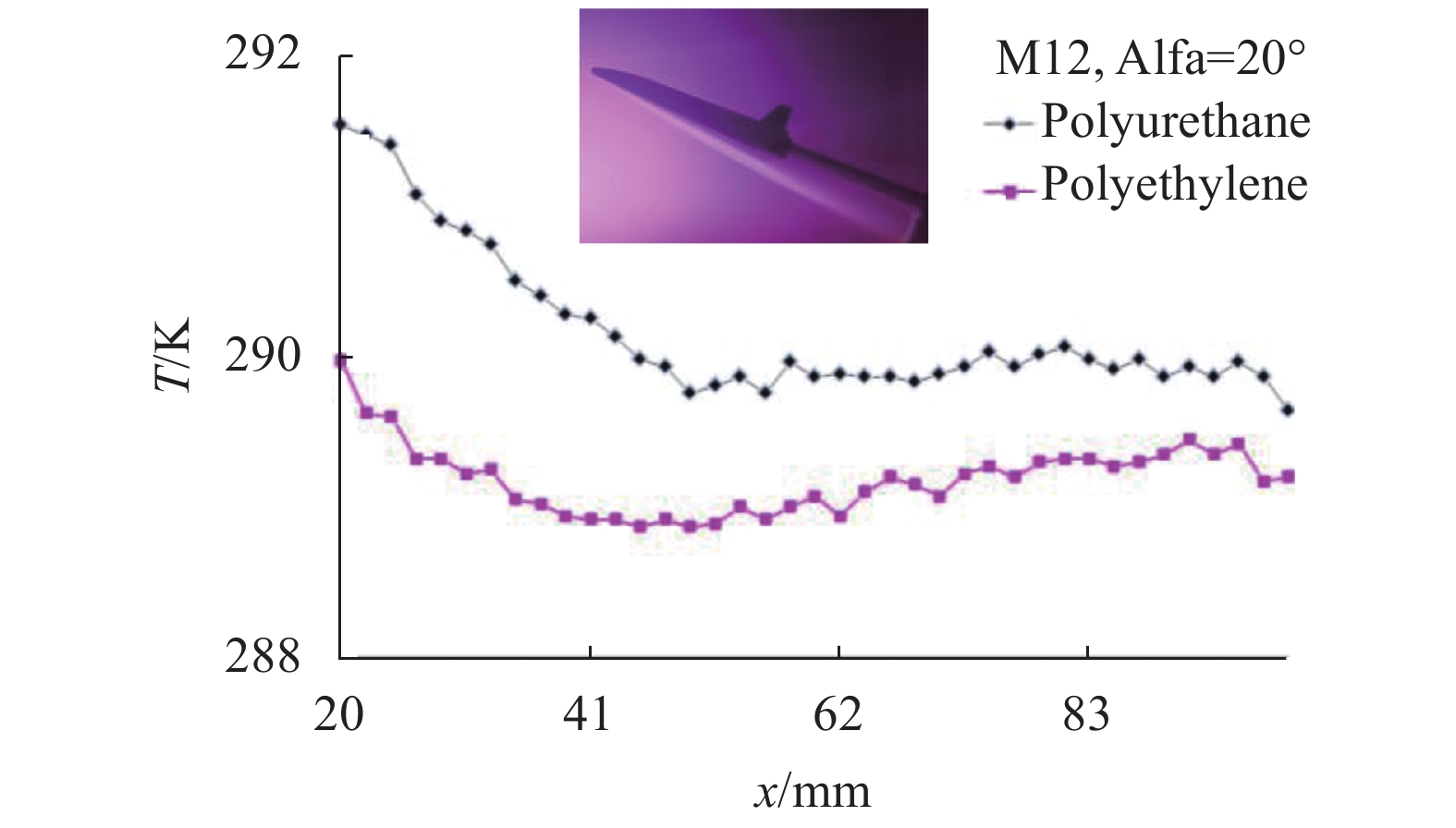

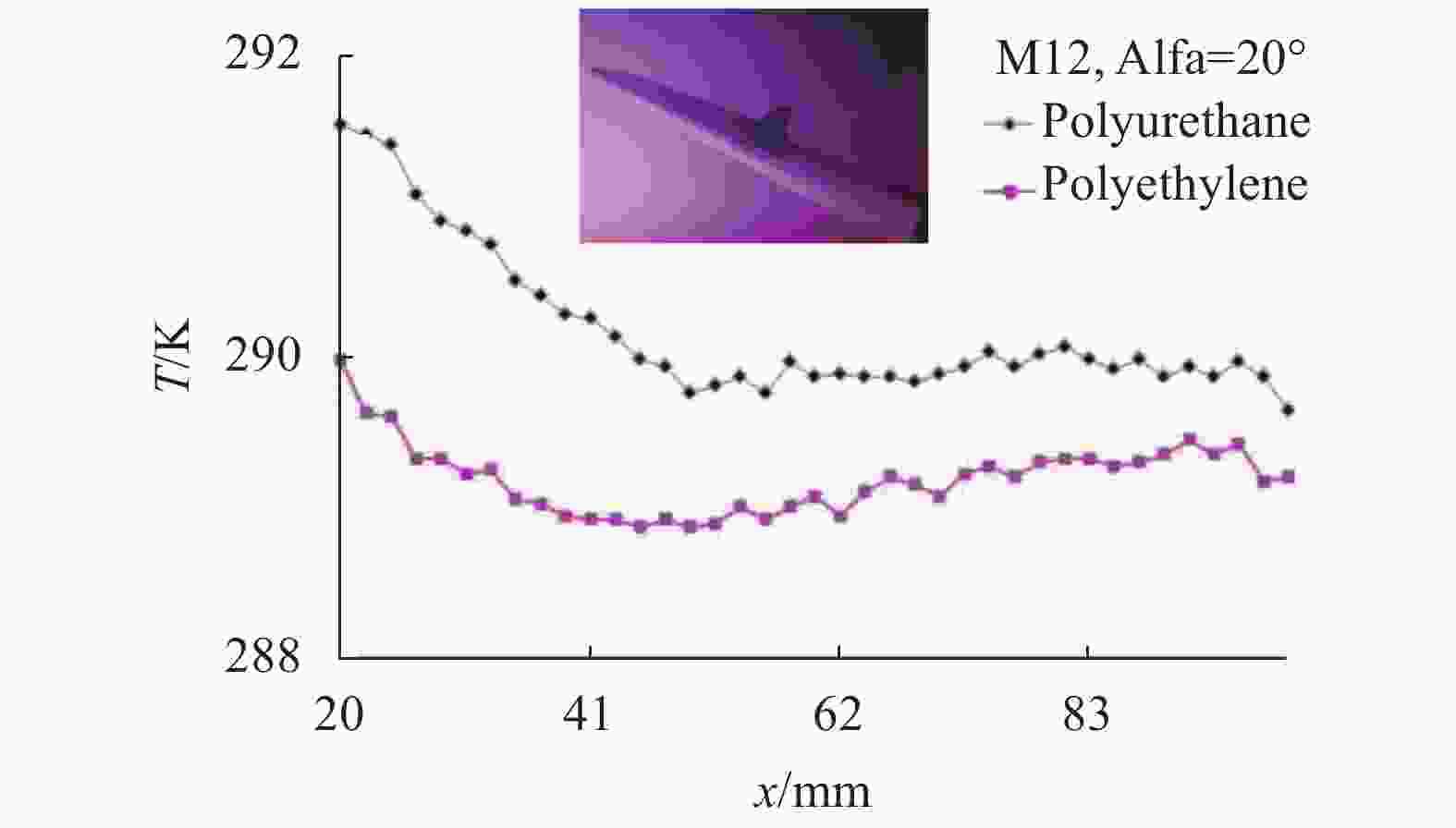

在稀薄流地面试验中,模型表面温升小,环境热辐射与模型表面热辐射相当,对红外测温结果影响比较大。增强红外检测信号有多种手段[12-16],文中为了增大模型表面红外辐射强度,选用聚四氟乙烯(其热扩散系数为4.68×e−7 m2/s)、聚酰亚胺(其热扩散系数为1.63×e−7 m2/s)两种不同热扩散系数的模型绝热材料,在马赫数12、驻室温度580 K、驻室压力100 KPa、攻角20°的试验条件下,通过红外热像仪测量某升力体模型表面温度,所获得该模型迎风面温度分布如图3所示。从图中可以看出,当模型材料热扩散系数降低2.9倍时,模型表面温升显著增大,从而提高了试验的信噪比。

-

模型材料的热物性参数标定一直存在不少的困难,过去,模型热物性参数标定误差为10%左右,是造成热流测量不准确的主要误差源。

采用瞬变平面热源法(Transient Plane Source Method, TPS)测量模型材料的热物性参数可以大大提高测量精度。该方法的原理为:在测试时将一平面探头放置在两片模型材料试样之间,假设包围探头的模型材料试样无限大且热流只在样品内部传递,通过施加足以引起探头温升几分之几度至几度的电流,得到时间与温度曲线,计算该曲线的斜率得到模型试样的导热系数,对该曲线进行拟合得到模型试样的热扩散系数,再由普朗特数定义得到材料比热容。该方法中,测试探头是整个测试的关键部件,探头由可导电的双螺旋结构绕线组成,绕线采用的是光刻的金属箔(镍丝),被夹在两绝缘薄层(Kapton, Mica等)之间。探头既被用作热源,也被用作动态温度探头。

在室温条件下,对试验使用的加碳粉的改性聚四氟乙烯(F4)材料的热物性参数进行了测量,该材料的密度、比热与热传导系数的乘积为1.2794×106 J2/M4·K2·s,模型材料导热系数测试精度达到3%,热扩散系数测试精度达到5%。

-

实验室使用的发射率测量仪,可以对3~5 μm、8~14 μm两个波段的模型表面发射率进行测量。采用以下几种方法,来提高模型材料表面发射率测量精度:通过漫反射补偿,减少环境辐射的影响;采用锁相技术和微电子技术,提高对微弱信号的探测。

-

对于壁厚小于1 mm的金属材料构成的模型(薄壁模型),采用薄壁量热法来获得模型表面热流分布,这种方法在一定条件下满足以下假设:沿着薄壁模型表面法线方向没有温度梯度,模型表面的热传导率与来流传给模型的对流换热率相比非常小,可忽略不计。当使用热电偶测量大量值热流时(例如MW/m2量级),一般是测量金属薄壁模型内壁面瞬态温度,当使用热电偶测量中低量值热流时(例如几kW/m2到几百kW/m2),一般是测量金属薄壁模型外壁面瞬态温度,从而获得模型表面热流;当使用红外热图方法时,是通过测量金属薄壁模型外表面瞬态温度,推算出模型表面热流。既然模型内外壁面没有温度梯度,那么在中低量值热流测量中,用热电偶测量模型内、外壁面热流与红外热图方法测量相比较,结果如何?

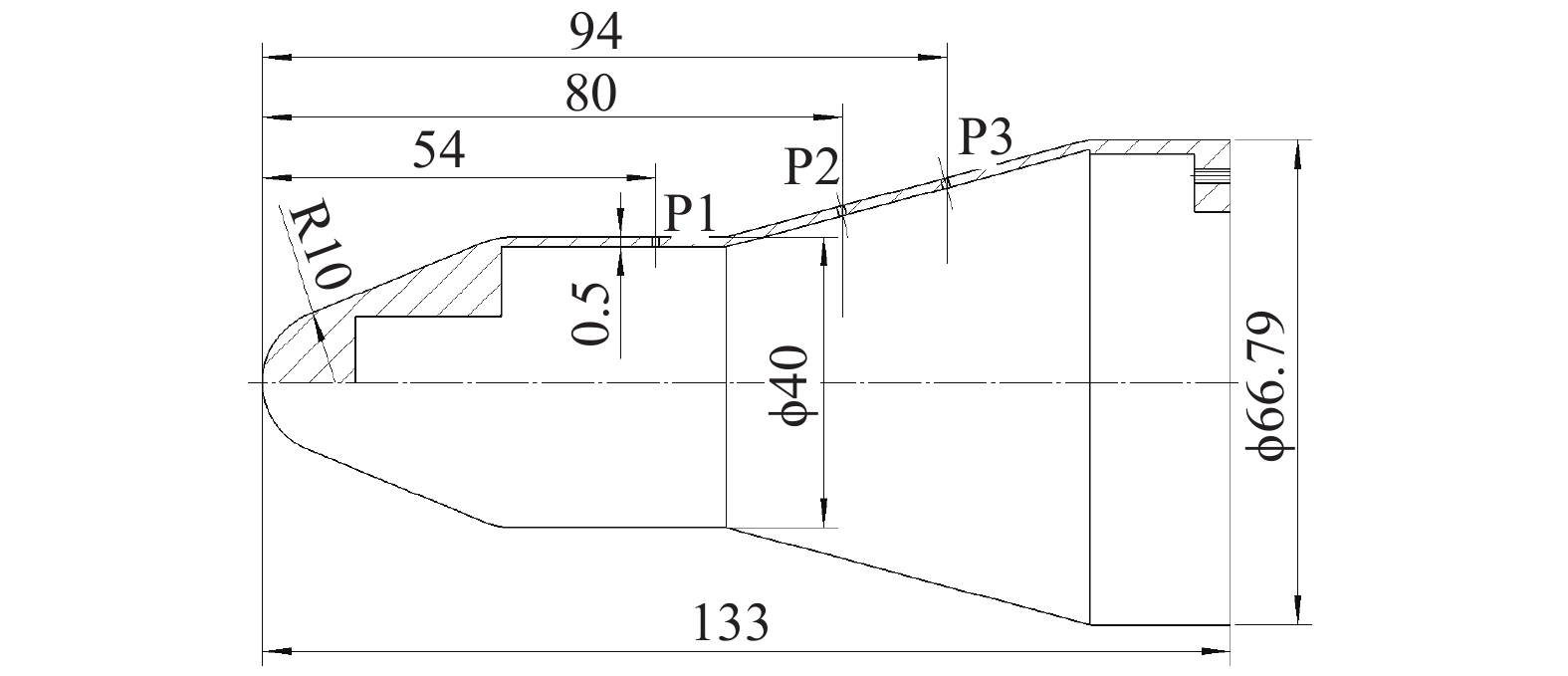

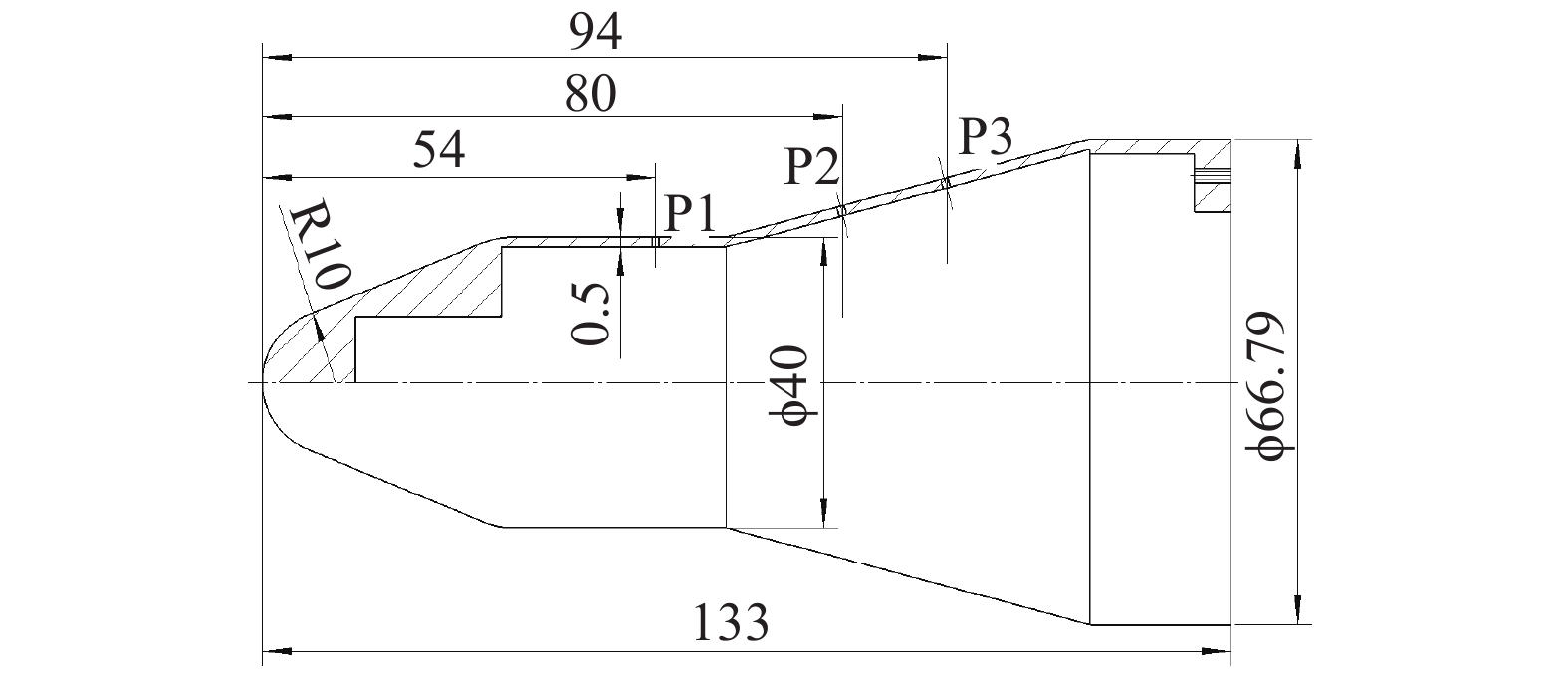

为此,在马赫数 Ma 为 12、试验总压P0 为4.2 MPa、试验总温T0=700 K、攻角20°试验状态下,用热电偶与红外热图同时测量双锥薄壁模型P1、P2、P3三个点热流,该模型外形及热电偶布置位置如图4所示,模型壁厚0.5 mm,前锥体半锥角为22.5°,后锥体半锥角为15°,采用不锈钢材料加工,在模型一侧的内壁面焊接了3支K型热电偶,在模型另一侧对称位置的外壁面也焊接了3支热电偶。为提高模型表面的发射率,对模型外表面进行了处理。

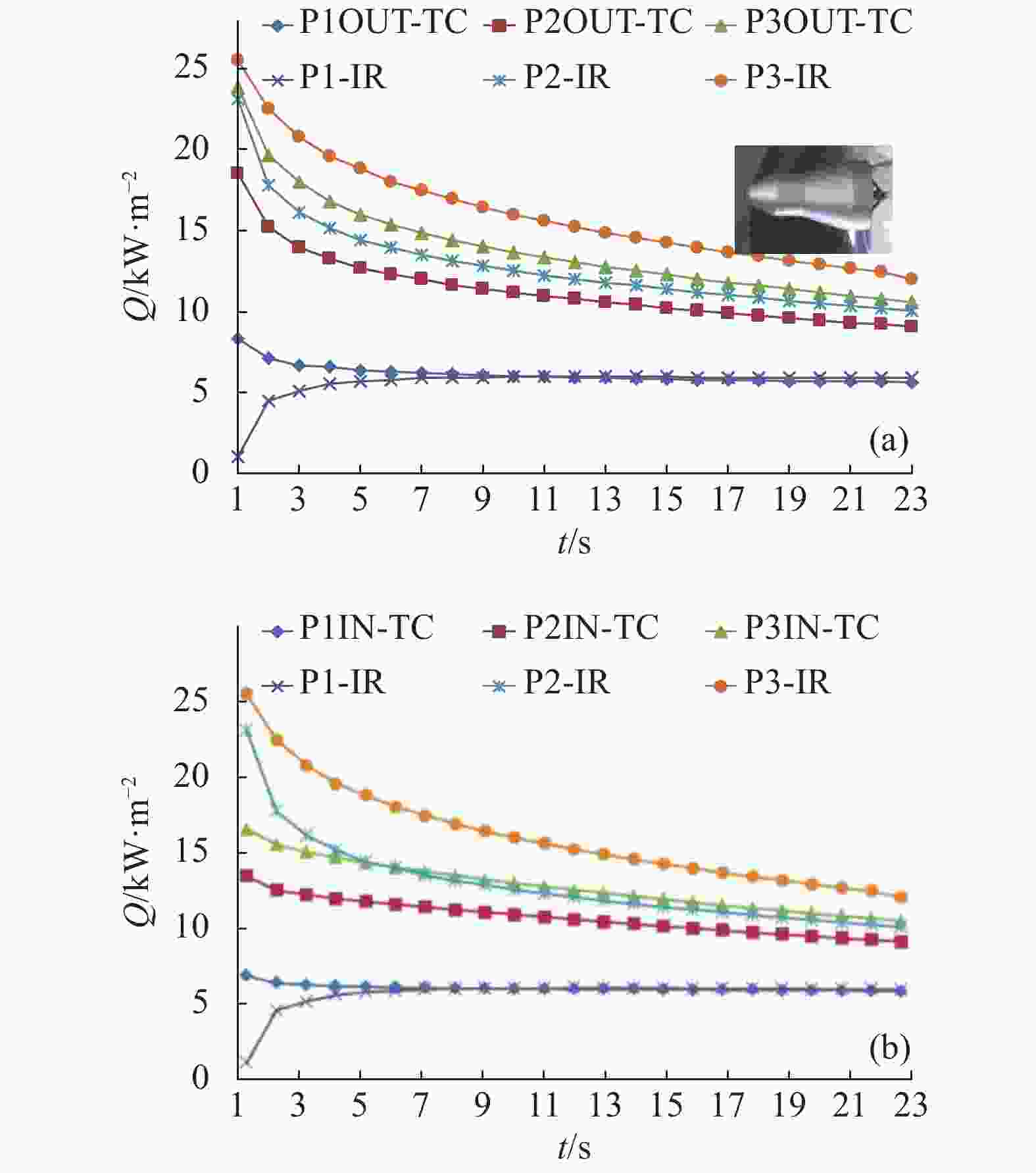

在不同模型加热时间,用热电偶测量模型P1、P2、P3三个点内壁面热流、外壁面热流与红外测量结果比较如图5所示(图中P1IN-TC表示用热电偶测量P1点内壁面热流,P1OUT-TC表示用热电偶测量P1点外壁面热流,P1-IR表示用红外热像仪测量P1点外壁面热流,其余类同)。结果表明:红外测量结果与热电偶测量外壁面结果更接近。测量时间越短,热电偶测量结果与红外测量结果差值就越大,而热电偶布置在外壁面位置所获得的热流大于布置在内壁面位置所获得的热流,模型加热时间对不同量值热流的测量结果的影响是不同的。对测量几kW/m2小量值热流来说(P1点),当模型加热时间小于3 s时,模型外壁面热流大于内壁面热流,当模型加热时间大于3 s时,模型内外壁面所获得的热流是一致的;对测量十几kW/m2量值热流(P2点),当模型加热时间小于8 s时,模型外壁面热流大于内壁面热流,当模型加热时间大于8 s时,内外壁面所获得的热流几乎相等;当模型壁面热流进一步增大时(P3点),在模型加热时间小于13 s时,外壁面热流大于内壁面热流,当模型加热时间大于13 s时,模型内外壁面所获得的热流也趋向一致。模型加热时间对热流测量结果的影响与前文的分析是一致的。从1~4 s,由于模型温升慢,P1点热流逐渐增大(一般情况下,模型起始时刻热流最大),这也与测量模型大量值热流是不一样的。

-

(1)在中低量值热流测量时,如何确定模型加热时间,是一项复杂的工作,需要综合考虑模型壁面定常热流假设与一维半无限大假设成立条件、减少模型表面侧向导热误差、控制模型表面温升等多种因素,合理确定该时间。

(2)在测量中低量值热流时,可选择较低热扩散系数模型绝热材料增大红外有用辐射信号,采用光学调制技术和漫反射补偿等方法提高模型表面发射率测量精度,采用瞬变平面热源法提高模型材料热物性参数标定精度。这些手段的综合运用可进一步提高中低量值热流测量的信噪比。

(3)在测量中低量值热流时,红外测热结果与热电偶布置在模型外壁面测量结果更接近,这与在激波风洞、电弧风洞等地面设备中测量模型表面大量值热流、将热电偶焊接在模型内壁面是不同的。

DownLoad:

DownLoad: