HTML

-

科学级电荷耦合器件(Charge Coupled Device, CCD)具有超低的读出噪声、超高的光电耦合效率、较宽的光谱响应范围以及高分辨率等优点,成为遥感领域广泛应用的光电成像器件[1-2]。多角度偏振成像仪(Directional Polarimetric Camera, DPC)作为陆地生态系统碳监测卫星主载荷之一,是由中国科学院安徽光学精密机械研究所研制的一种超广角、画幅式和低畸变成像的星载偏振传感器,主要由成像物镜组件、装载偏振片和光谱滤光片的检偏滤光组件、面阵CCD探测器及电子学单机构成。探测器要获得高质量的图像信号输出,需要精确的驱动时序、低噪声的偏置电压和高精度模拟前端性能的保证[3-5]。

DPC运行于505 km的太阳同步轨道,在轨期间遭遇的捕获电子和捕获质子辐射环境将诱发电子器件产生单粒子效应,影响星载偏振相机在轨工作安全,其中单粒子锁定(Single Event Latch-up,SEL)现象发生时可在芯片的供电端和地平面之间形成低阻通道,使器件的工作电流增加几倍并维持大电流状态,导致器件功能丧失甚至烧毁[6-7]。长期以来,国内外对于电子器件的单粒子效应做了大量的研究。2002年,法国波尔大学的F. Darracq等首次利用激光从商用SRAM器件背面扫描照射方法测试了器件的SEU和SEL效应的阈值和截面,突破激光无法正面穿透多层金属布线层的技术瓶颈[8];日本的Takahiro Tomioka等针对纳米卫星上的微处理器使用锎−252(252Cf)源进行单粒子锁定效应试验研究[9]。2010年,美国sandia国家实验室使用0.35 μm SOI工艺设计了具有不同SEU阈值水平的SRAM阵列,分别进行了脉冲激光和地面重离子试验,初步建立了两者之间的定量关系[10]。国内,曹洲等针对新型商业器件大容量NAND Flash存储器,利用皮秒脉冲激光和高能重离子开展了单粒子试验研究[11];汪波等针对8T-CIS图像传感器进行重离子辐照实验,研究其单粒子翻转的敏感性及损伤机理[12];韩建伟等建立便捷、低成本的脉冲激光定量试验的手段,针对多种数字器件及DC/DC电源模块进行了单粒子效应研究[13]。目前,针对微处理器、CMOS图像传感器和现场可编程门阵列(FPGA)等器件的单粒子辐射效应机理及防护设计验证的报道较多,而针对航天用模拟前端器件的单粒子效应试验研究报道较少。

模拟前端(Analog Front-End, AFE) 是图像传感、工业控制和数码产品等电子系统中实现前端模拟输入信号到后端数字处理信号转换的关键环节[14-15]。在星载偏振相机领域内,模拟前端是面阵CCD成像系统的核心部分,用于读出像元电荷并完成图像的采集、转换和传输,将经过降噪和调幅处理的CCD图像信号量化成数字图像信号并传输至视频处理器。DPC采用的模拟前端为ADI公司生产的宇航级器件,是专门为CCD/CIS成像器件设计的高速A/D转换芯片,其分辨率为14 bit,最大转换速度为10 Msps[16]。该器件已大量应用于多颗卫星型号的光学载荷中。典型的模拟前端一般由高速高精度模数转换单元、可变增益放大单元和相关双采样保持单元等对单粒子效应敏感的电路模块组成,且AFE电路为数模混合电路,电路设计上需考虑模拟电路和数字电路之间的相互影响,模拟电路和数字电路分开布局,并分别采用独立的电源和地平面使其保持紧密耦合,以减小电源平面和地平面的阻抗。单粒子效应可能会引起模拟前端的非线性误差、输出噪声、动态功耗等性能退化甚至失效,发生单粒子锁定后多个像素的图像数据对应的像元灰度值偏离正常范围,显示黑条,甚至没有图像输出,且器件电源端工作电流发生明显增加,从而威胁星载偏振相机在轨任务的正常运行。

文中针对多角度偏振成像仪选用的集成度高、工艺复杂的宇航级模拟前端信号处理器,利用重离子地面模拟源和皮秒脉冲激光单粒子效应试验系统,开展CCD成像系统中模拟前端的单粒子锁定模拟试验与抗锁定加固防护研究,研究结果可为空间应用环境下的宇航型号模拟前端选型、抗辐加固设计及单粒子地面试验评估提供技术基础与保障。

-

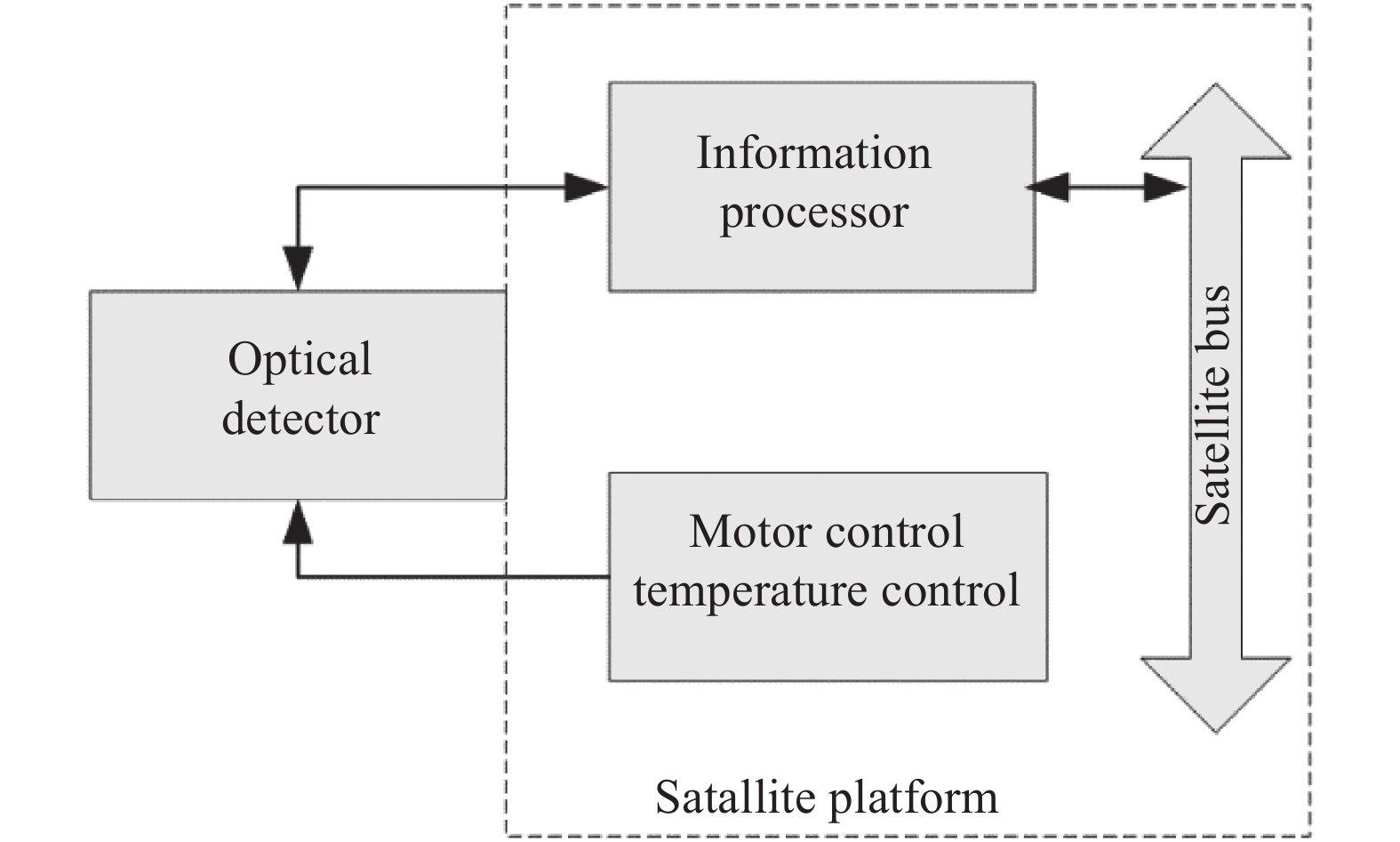

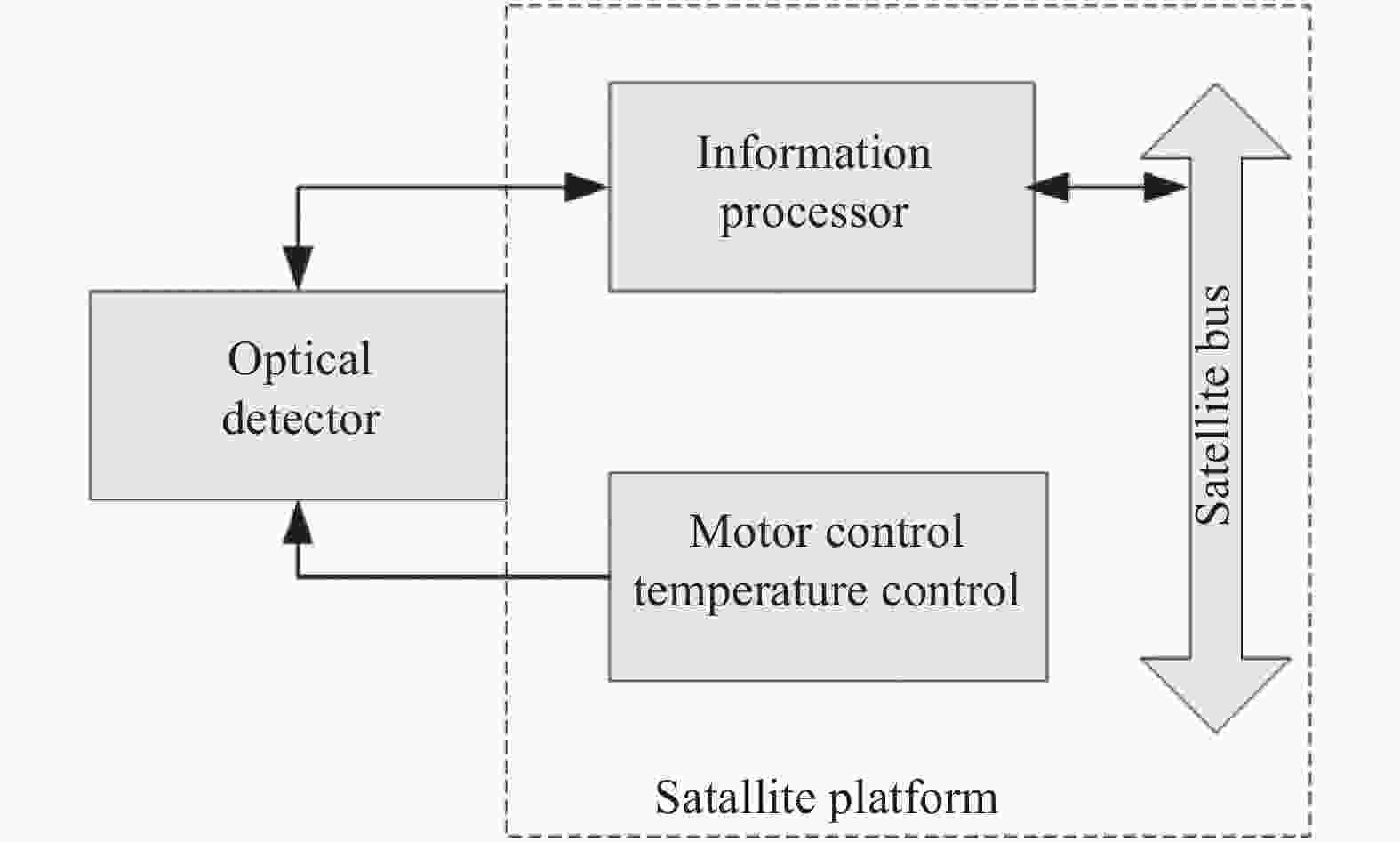

DPC是以业务化运行为目标的大视场星载偏振传感器[17-19],按结构可分为三个部分,功能如图1所示:光机头部为前端光学探测部分;信息处理箱为总控单元,负责载荷与卫星数管分系统的连接及信息交换;驱动控制箱实现步进电机运动控制及光机头部各部件的温度控制。信息处理箱和驱动控制箱安装于卫星舱内,光学头部安装于舱外且与卫星平台隔热安装。光机头部中的探测器成像系统如图2所示,由面阵CCD探测器和头部电路盒组成,实现探测器的驱动与视频信号采集,完成光电转换后输出的数字信号传输至信息处理箱。

面阵CCD输出的图像模拟信号经预放器放大后送入模拟前端进行隔直、降噪等处理,在相关双采样及控制脉冲的作用下经模数转换成相应的数字信号,然后送进FPGA内部按照科学数据包格式进行组织打包,通过LVDS接口将打包后的图像数据传送至信息处理箱。模拟前端位于信号流的起始阶段, 其输出已经转变成数字信号,后续数字电路几乎不受干扰,因此模拟前端对探测器成像系统信噪比起重要作用[20-21]。空间高能带电粒子入射至模拟前端器件敏感区时可能触发寄生晶体管导通而产生单粒子锁定效应,从而造成器件的功能丧失,同时工作电流异常增加并维持此状态,对探测器成像系统造成严重威胁。

-

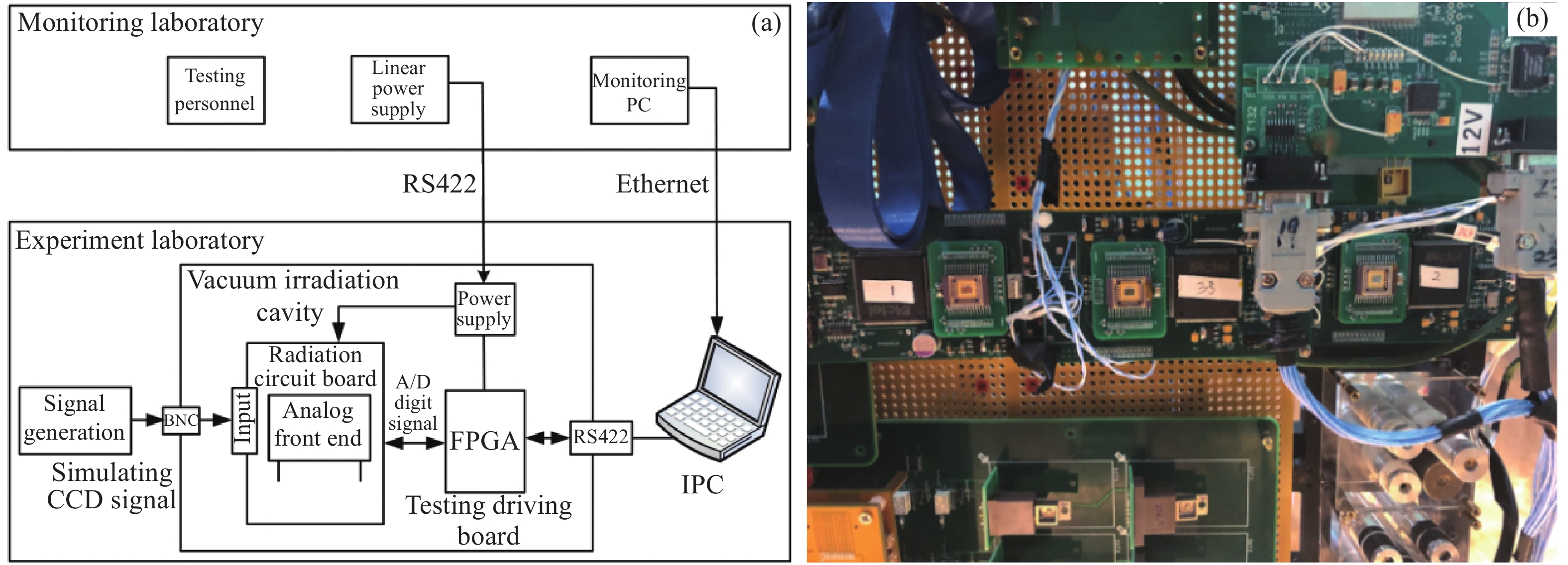

模拟前端的单粒子锁定试验测试系统如图3所示,包括辐照试验板、信号处理板、信号发生器、主控计算机和远程控制计算机等。辐照板用于焊装接受重离子辐照的受试器件,并通过插座安装在信号处理板上;信号处理板用于实现受试器件的供电控制、信号采集和实时无损传输等功能;信号发生器提供各通道的模拟信号输入;主控计算机放置于试验大厅,通过串口进行通信和数据传输,实现对信号处理电路的远程控制,通过地检软件控制线性电源,实现电流实时记录和限流保护功能;监控计算机放置于测试大厅,通过路由器与主控计算机通信,具有信号在线检测,改变器件增益、偏置参数和功能中断时在线重启等功能。

Figure 3. single-particle online detection system. (a) Principle block diagram; (b) Photo of AFE in radiation field

试验在中国原子能科学研究院的HI-13串列静电加速器上完成[22],为确保重离子入射器件的灵敏区以诱发单粒子效应,试验前对被测器件进行专业开帽处理,重离子从器件正面入射,其束斑尺寸为30 mm×30 mm,可覆盖被测芯片表面。选用不同线性能量传输(Linear Energy Transfer,LET)值的重离子进行试验,表1给出了重离子种类、LET(MeV·cm2·mg−1)值、射程(半导体材料硅中射程)、入射角度、注量率和试验所处环境等信息。

Ion specie Incident angle LET/MeV·cm2·mg−1 Energy/MeV medium range/μm Flux/ion·cm−2·s−1 Experimental environment Ge Vertical 37.3 208 30.3 10900 Vacuum tank Cl Vertical 13.4 150 42.8 13500 Vacuum tank F Vertical 4.4 100 72.7 25400 Vacuum tank Table 1. Ion parameters of heavy ion irradiation test

试验过程中通过单粒子辐照测试软件获取单粒子事件信息,测试软件具备实时更改AFE内部的采样频率、增益和偏置参数的功能,实时对模拟信号进行图像采集。试验测试方法如下:在受试器件的任意一路模拟信号输入端施加不同频率的三角波信号,改变增益和偏置的组合,查看模拟前端输出的数字码信号是否正确,并在监控界面上实时显示。

-

单粒子锁定发生时,可观察到器件的输出码值出现异常,表现为不同增益和内部偏置组合测试条件下受试器件的采样点和输出码出现不对应现象,即出现乱码。且器件电源端工作电流发生明显增大现象,工作电流从正常的50 mA增加到297~371 mA。

不同重离子辐照试验下AFE器件产生单粒子锁定的试验情况如表2所示。试验结果表明: AFE器件单粒子锁定LET阈值处于4.4~13.4 MeV·cm2·mg−1之间,发生锁定时器件的最大工作电流为371 mA,锁定发生后通过断电后重新上电,芯片恢复正常工作。

Ion

specieLET/

MeV·cm2·mg−1Flux/

Ion·cm−2·s−1Working current of

the device/mALimiting current of

power supply/mADynamic

output signalQualified

or notConclusion Initial 0 0 49 500 Around 4B0H Yes The chip is normal Ge 37.3 10900 371 500 Around FFFFH No SEL occurred After Ge 0 0 49 500 Around 4B0H Yes The chip is not damaged Cl 13.4 13500 297 500 Around FFFFH No SEL occurred After Cl 0 0 49 500 Around 4B0H Yes The chip is not damaged F 4.4 25400 49 500 Around 4B0H Yes The chip is normal After F 0 0 49 500 Around 4B0H Yes The chip is normal Table 2. AFE test data of heavy ion irradiation

-

空间应用环境下无法避免使用单粒子锁定敏感器件时,通常采用在器件电源输入端额外串联电阻限制锁定异常大电流,并保护器件和电路在短时间内不被烧毁,同时采取断电重新上电措施以消除锁定状态。限流电阻选取需要考虑三个因素:(1) 限流电阻不宜过小,能够将高于十倍以上正常电流的锁定电流限定在较小范围;(2) 限流电阻不宜过大,确保限流电阻分担的压降不影响器件正常工作;(3) 当器件发生SEL时,限流电阻产生的更高压降也不会将整个系统的工作电压拉低至正常工作水平之下。

DPC选用的AFE器件内部有模式、状态、增益和偏置配置等寄存器,卫星在轨期间遭遇的地球内辐射带电高能粒子辐射环境将诱发AFE器件产生单粒子锁定,导致内部寄存器状态发生变化,从而使得探测器图像无法正常输出。为确保模拟前端遭受空间高能粒子辐照后配置的数据准确可靠,可从以下方面对星载偏振相机空间应用过程中抗单粒子锁定进行加固防护设计。

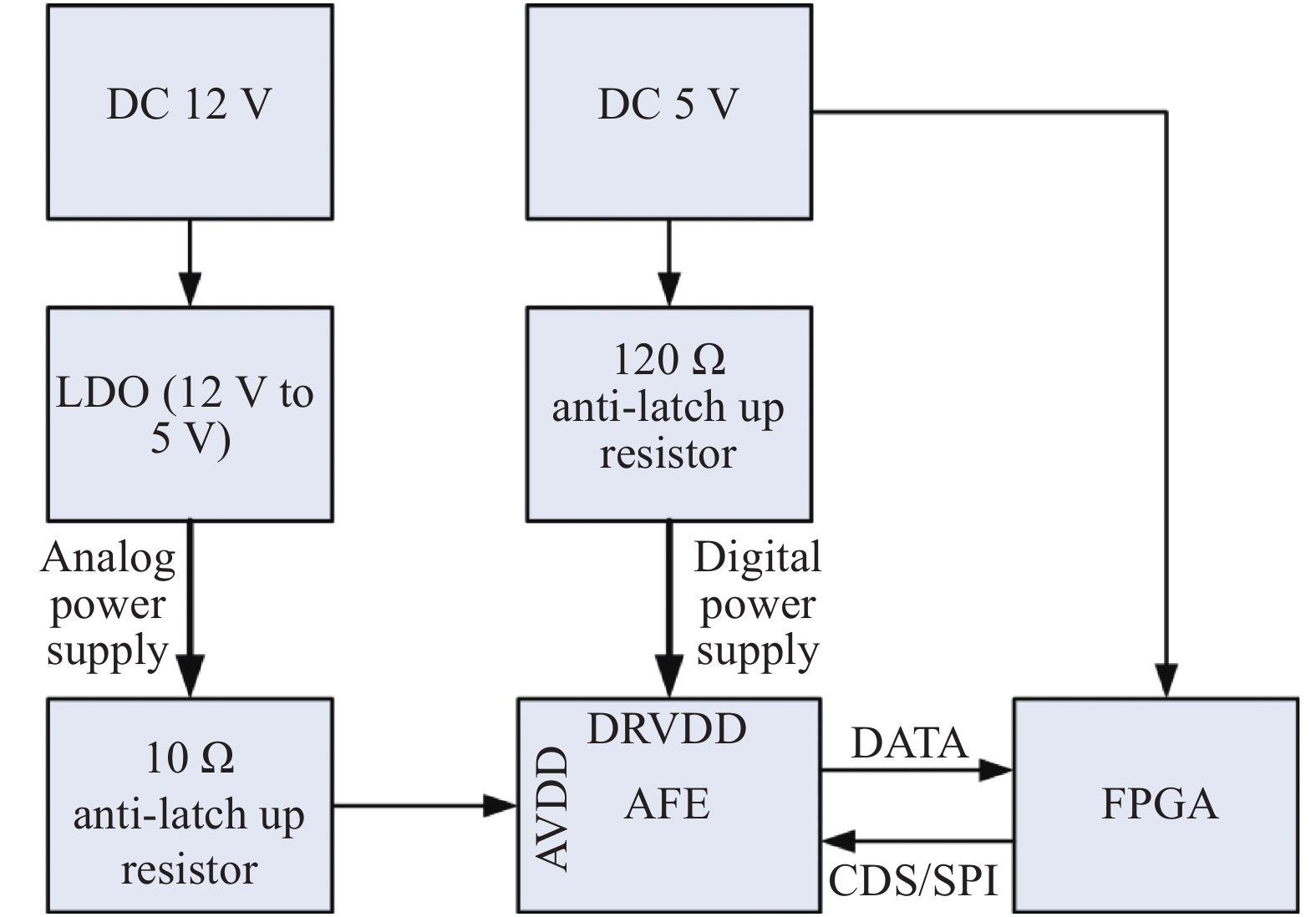

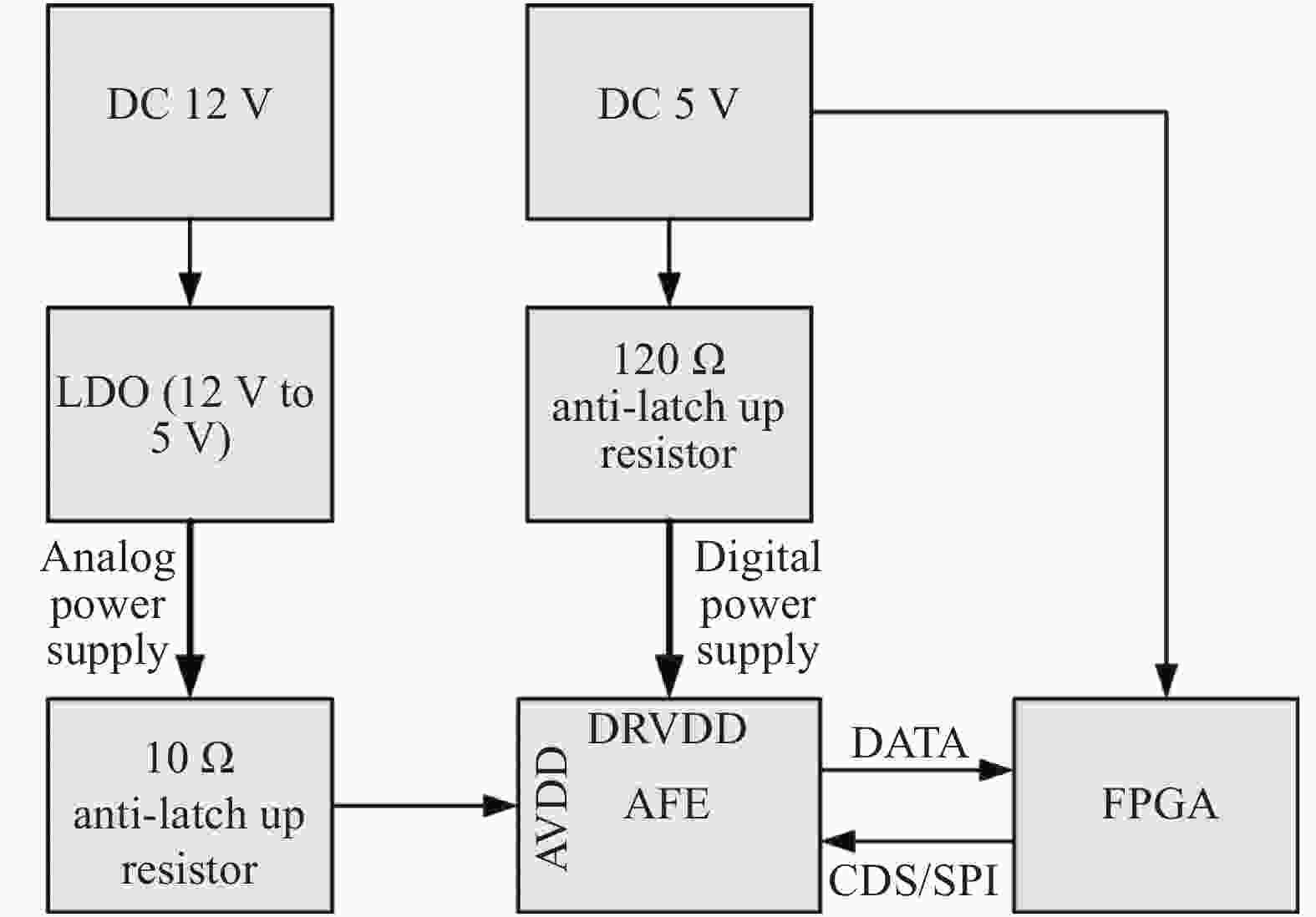

(1)芯片数字供电端和模拟供电端串联大功率防闩锁限流电阻。

AFE电路为5 V供电的数模混合电路,由CMOS设计标准可知,CMOS数字电路锁定效应的维持电流一般不小于40 mA,因此回路总电阻应不小于125 Ω。由重离子辐照试验结果可知,AFE芯片发生单粒子锁定时,最大锁定电流约为371 mA,计算可知AFE芯片内阻约为14 Ω。数字端限流电阻的阻值应不小于111 Ω。由器件使用手册可知,AFE芯片数字端正常工作的电压范围为3.00~5.25 V,正常工作电流约1 mA,最大不超过10 mA。为保证芯片正常工作,需要保证芯片工作电压不能低于3.5 V (0.5 V为降额设计考虑),因此限流电阻上压降不能超过1.5 V,计算可知串联电阻阻值不能超过150 Ω。综上所述,数字供电端限流电阻的取值范围为111~150 Ω,结合元器件库存情况,最终数字供电端选取120 Ω限流保护电阻,产生的压降为0.12 V,此时芯片数字端供电电压为4.88 V,满足芯片正常工作需求,也满足IO接口TTL电平的应用需求。

单路模拟供电端正常工作电流约18 mA,最大不超过40 mA,模拟供电端正常电压范围为4.75~5.25 V,考虑5 V供电电压,则最大串联电阻阻值不能超过14 Ω,结合元器件库存情况,最终两路模拟供电端分别串联10 Ω限流保护电阻,产生的压降为0.18 V,此时芯片模拟端供电电压为4.82 V,确保模拟前端芯片正常工作。

(2)参数配置回读校验。光机头部上电工作后,信息处理箱通过422总线将模拟前端参数发送给FPGA芯片,使用SPI接口对模拟前端进行参数配置,然后每次成像前对模拟前端工作参数通过内存下卸进行校验判断。

(3)输入端没有悬空。系统设计时将模拟前端未使用的引脚经电阻接电源或接地,减少输入端不定态,防止因输入异常诱发锁定。

(4)设置在轨断电重启指令。在轨运行期间对DPC载荷设置定期开关机遥控指令的方案应对,采用每轨成像前对光机头部定时关机后重新上电方式解除单粒子状态,保证单机工作正常。

DPC运行于505 km的轨道高度,在轨飞行时一轨运行周期为95 min,以开始成像入光点指令为一个工作循环周期内部时刻的零时刻,信息处理箱收到入光点指令后,在每轨第4 min对光机头部进行断电,断电维持5 s后对光机头部重新上电,光机头部在第5~55 min进行图像数据采集,其他时间处于待机状态。当模拟前端在一轨的任意时刻发生锁定,最坏情况是光机头部刚上电就发生锁定,则最长锁定时间为一轨运行时间95 min。

-

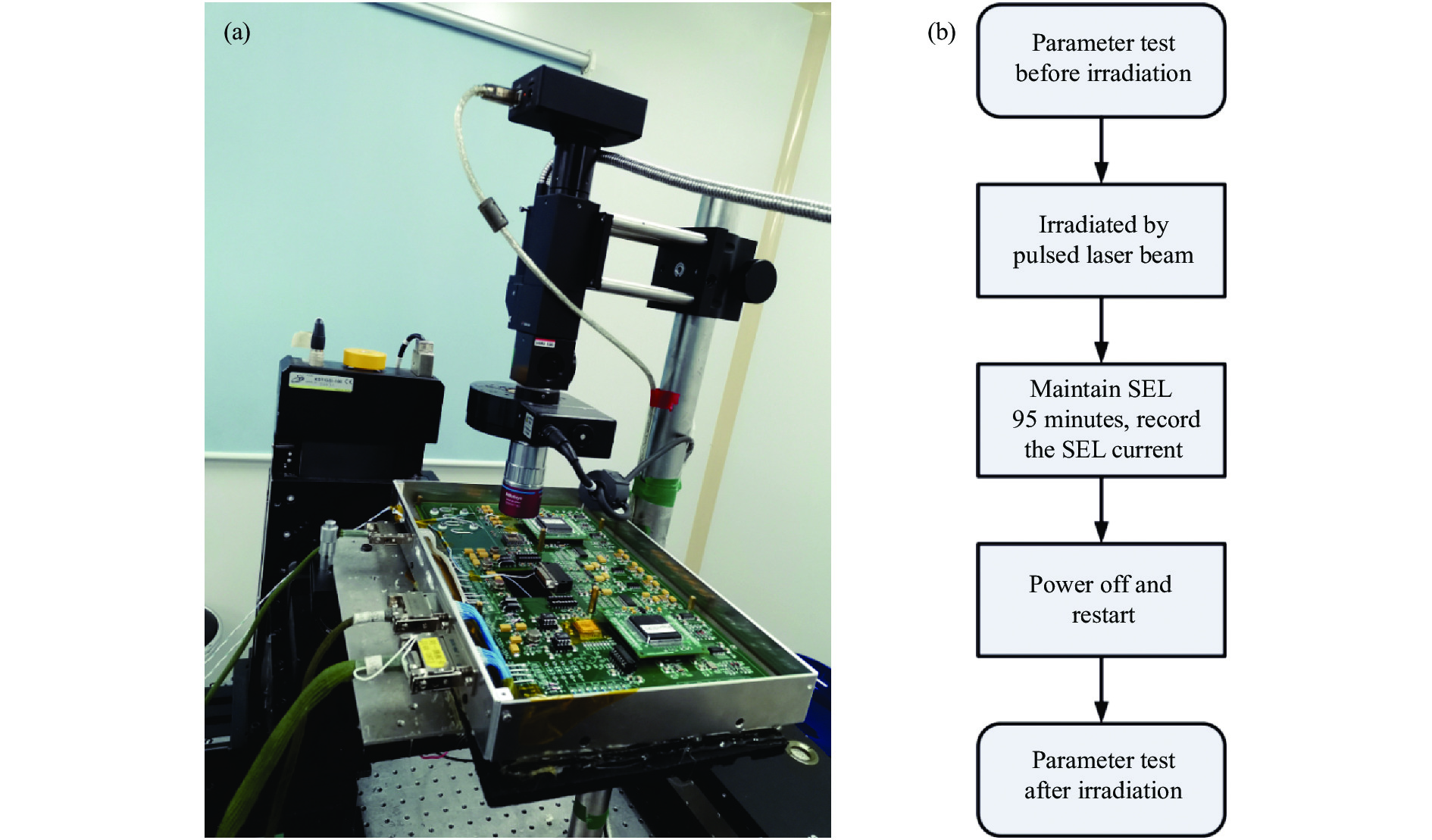

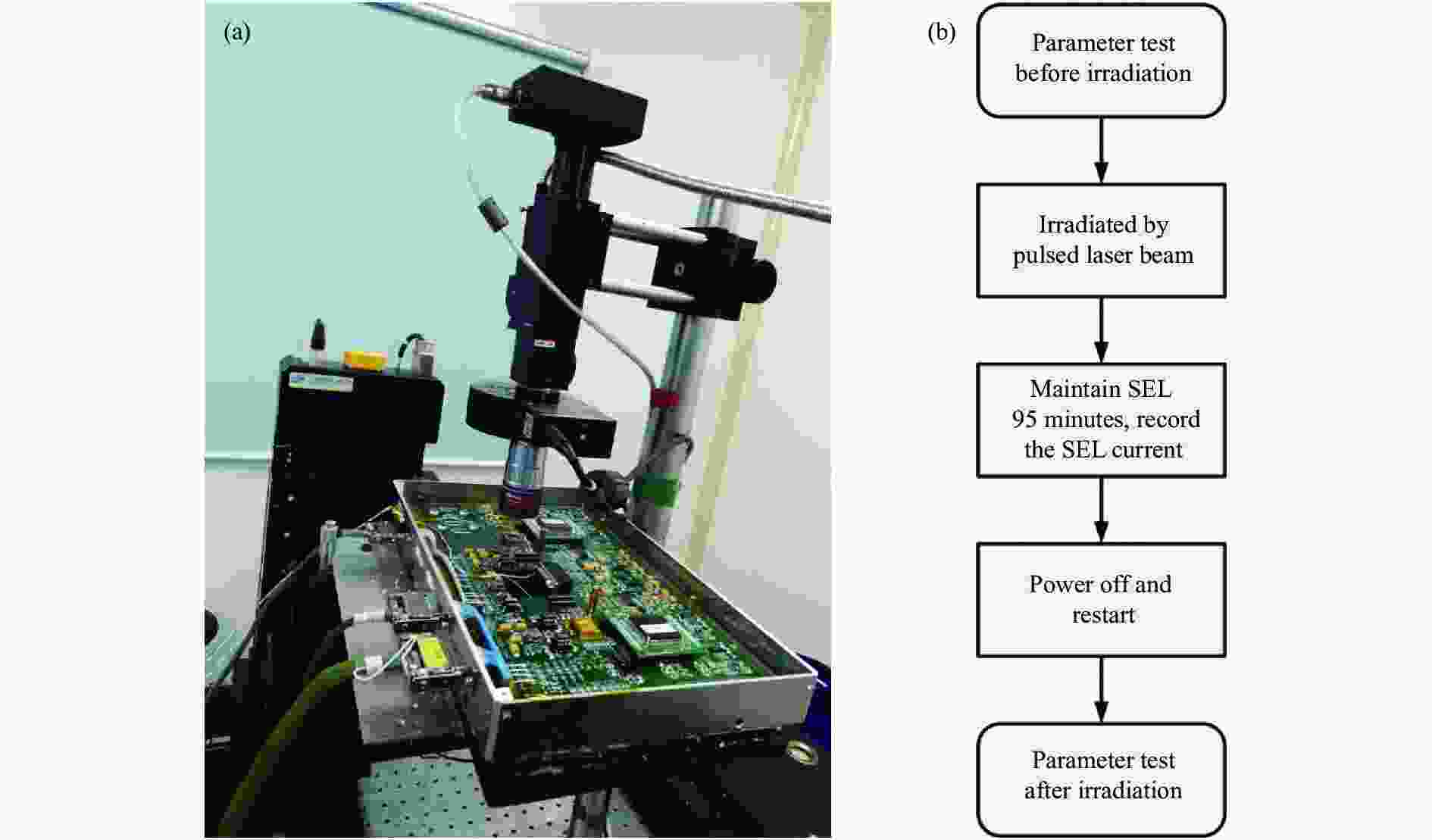

为了验证上述防护措施的有效性,开展了皮秒脉冲激光单粒子锁定防护验证试验,如图4所示。采用激光模拟高能带电粒子,AFE芯片尺寸2800 μm×3850 μm,激光光斑尺寸2 μm左右,配合移动精度为1 μm的三维精密移动平移台,沿着“弓字形”扫描整个芯片区域。AFE芯片的数字电源和模拟电源分别用线性电源供电。为了模拟DPC在轨实际运行状态,当激光照射使芯片锁定后维持95 min,再对其进行断电重启。

激光单粒子试验情况及结果如表3所示。由表3可知,当AFE芯片发生锁定且锁定状态维持95 min后,芯片没有出现烧毁现象,对电路盒进行断电重启,芯片能正常工作,模拟前端寄存器通讯正常,图像转换正常。数字端在限流保护电阻的情况下,芯片发生锁定时有效降低锁定异常电流(锁定电流维持在11 mA),避免器件的功能损伤。模拟端在限流保护电阻的情况下将锁定电流维持在510 mA。

LET by Laser simulation/

MeV·cm2·mg−1Number

of testsDigital power

current/mAAnalog power

current/mAInternal register

communicationImage

output/DNConclusion 0 Before test 1 37 Normal 823 Normal 75 First 11 496 Abnormal 16383 SEL occurred Maintain SEL 95 min Laser stop 1 496 Abnormal 16383 SEL occurred Power off and restart After test 1 37 Normal 826 Back to normal 37 Second 11 510 Abnormal 16383 SEL occurred Power off and restart After test 1 37 Normal 826 Back to normal Table 3. Test data of pulsed laser irradiation

-

(1)功耗影响分析

光机头部电路盒中模拟前端的供电如图5所示,数字端电源由DC5V模块经防闩锁限流电阻直接供电,DC5V模块同时给数字信号处理器供电,模拟端电源由DC12V模块经LDO转换后供出。AFE芯片发生单粒子锁定后,根据各供电电压及对应供电电流的变化,可计算模拟前端芯片内部各部分功耗,同时DCDC电源模块、LDO线性稳压器和FPGA芯片的工作电流也会上升。计算结果如表4所示。

Item Value Increased power consumption of AFE after SEL/W 1.136 Increased power consumption of LDO after SEL/W 3.234 Increased power consumption of FPGA after SEL/W 0.5 Increased power consumption of DC12V after SEL/W 0.158 Increased power consumption of DC5V after SEL/W 0.301 Increased power consumption of circuit box after SEL/W 5.329 Increased current of primary power supply after SEL/A 0.175 Total current of primary power supply after SEL/A 0.529 Table 4. Increased power consumption of optical detector after SEL of the AFE

由表4可知,AFE发生锁定后,其模拟供电端的10 Ω限流电阻的功耗分别为0.698 W和0.511 W,数字供电端120 Ω限流电阻的功耗为0.015 W,AFE芯片自身增加的功耗为1.136 W。防闩锁限流电阻均为1206封装,其额定功耗为0.25 W,发生锁定后该电阻功耗高达0.698 W,已经为额定功率的2.79倍,有发热烧毁的风险。

AFE的模拟供电由LDO线性稳压器提供,当AFE发生锁定后增加的电流全部由线性稳压器提供,其增加的功耗为3.234 W。

DCDC模块额定功率为15 W,按一级降额因子0.75要求,允许工作的最大功率为11.25 W。发生锁定后DC12V模块输出功耗为6.125 W,DC5V模块输出功耗为1.689 W,均小于最大功耗要求,说明AFE发生锁定后对DCDC模块没有影响。

AFE发生锁定后其数字输出端口被拉到高电平,导致与数字端口连接的FPGA芯片工作电流上升0.1 A,发生锁定后FPGA功耗增加了0.5 W。

由以上计算可知,AFE发生锁定后光机头部电路盒增加的总功耗为5.329 W,光机头部一次母线供电电流增加0.175 A,一次母线总电流为0.529 A。光机头部电路盒一次母线电源端选用的保险丝额定工作电流为2.1 A,按照一级降额因子0.65的要求,允许工作的最大电流为1.365 A。因此,当AFE发生锁定后光机头部一次母线电源端保险丝处于正常工作范围,没有烧断风险。AFE芯片属于DPC载荷光机头部内部功能芯片,对单机外部接口无任何影响,当存在锁定风险时,对其他单机无任何影响。

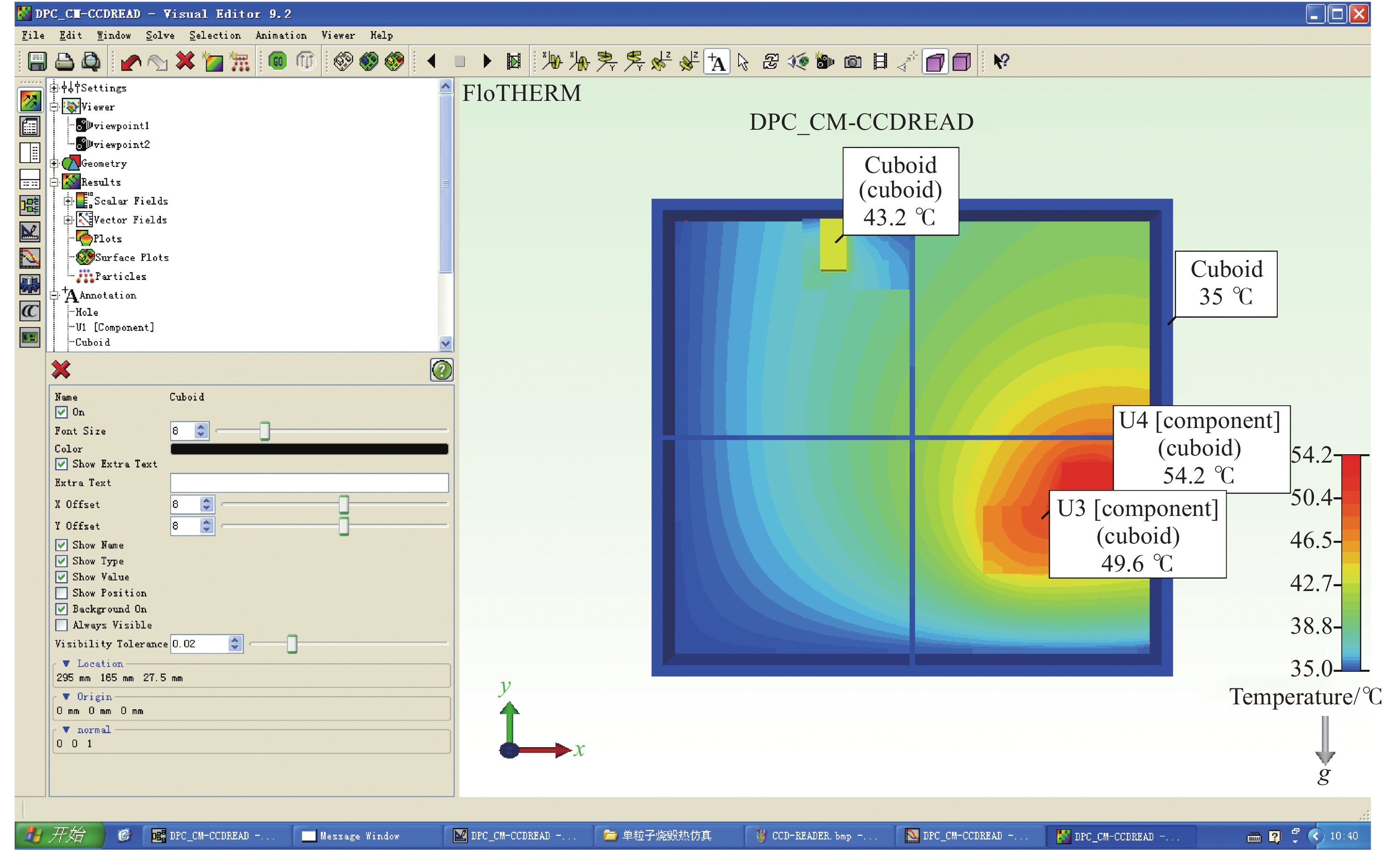

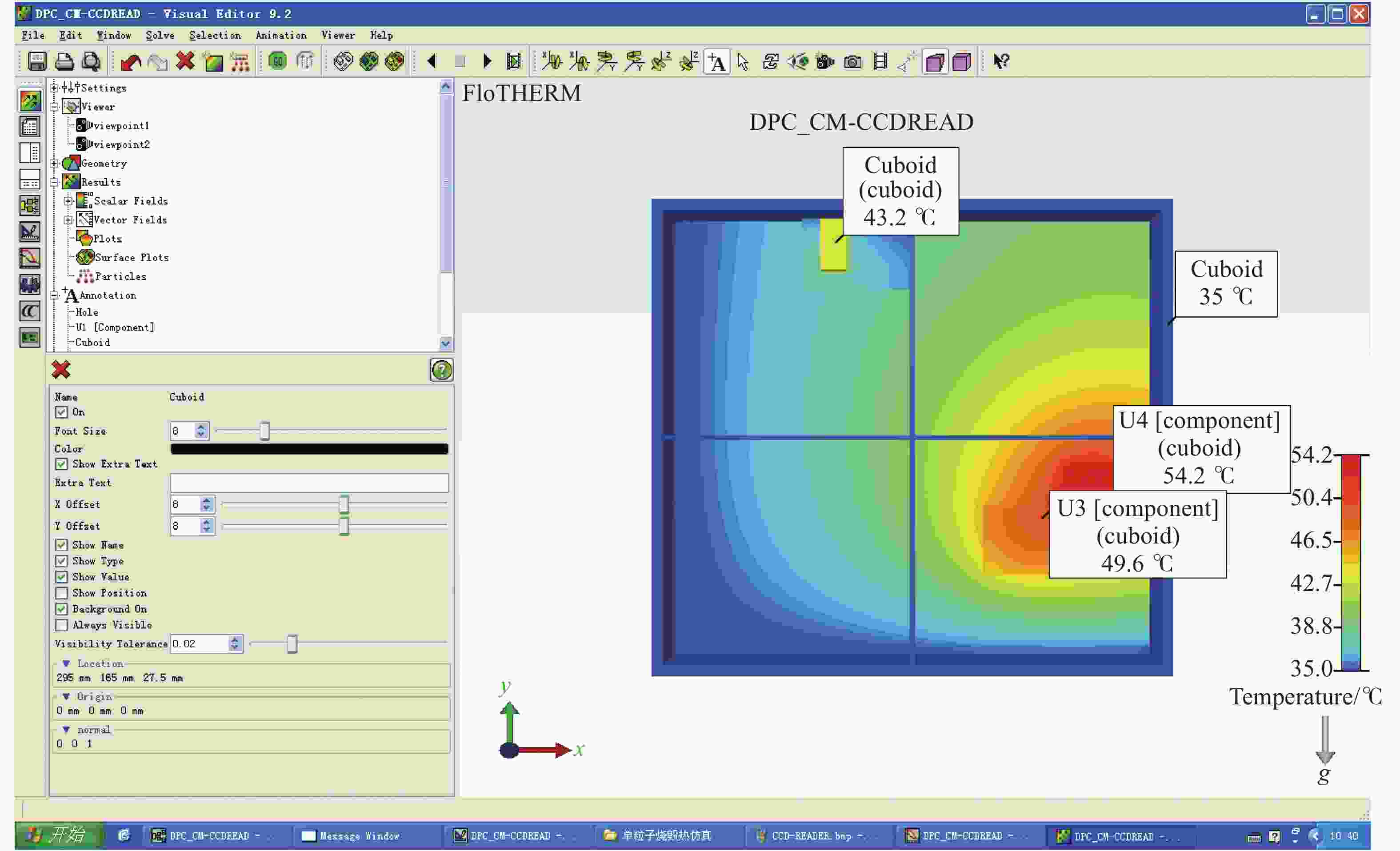

(2)芯片工作温度影响分析

使用电子学热仿真分析软件对发生锁定状态的光机头部电路盒进行热分析,边界条件为真空条件电路盒外壳温度35 ℃,当模拟前端发生单粒子锁定后,光机头部电路盒中的大功率发热器件有LDO线性稳压器、AFE芯片和FPGA芯片。其中LDO线性稳压器贴壳散热,通过结构件散热。FPGA和AFE芯片贴焊在印制电路板上,通过引脚散热。LDO线性稳压器结壳热阻

$ {\rm{\theta }}_{\rm{J}\rm{C}}=2$ ℃/W,最大结温150 ℃,考虑一级降额,结温不能超过85 ℃,发生锁定后功耗3.57 W。AFE结壳热阻$ {\rm{\theta }}_{\rm{J}\rm{C}}=22 $ ℃/W,最大结温$ 150 $ ℃,考虑一级降额,结温不能超过85 ℃,发生锁定后功耗1.38 W。FPGA结壳热阻$ {\rm{\theta }}_{\rm{J}\rm{C}}=6.3$ ℃/W,最大结温$ 150 $ ℃,考虑一级降额,结温不能超过85 ℃,发生锁定后功耗为0.8 W。热仿真结果如图6所示,发生锁定后芯片工作温度计算结果如表5所示。Device Heat consumption

after SEL/WJunction-to-

case thermal

resistance, θJC /℃·W-1Simulation case

temperature/℃Max junction

temperature/℃Level derating

requirement/℃Accordance AFE 1.38 22 54.2 84.6 ≤85 Yes LDO 3.57 2 43.2 50.4 ≤85 Yes FPGA 0.8 6.3 49.6 54.6 ≤85 Yes Table 5. Calculation results of working temperature after SEL

由表5可知,当AFE芯片发生锁定后,AFE芯片壳温达到54.2 ℃,由计算可知对应结温为84.6 ℃,线性稳压器壳温达到43.2 ℃,对应结温为50.4 ℃;FPGA芯片壳温达到49.6 ℃,对应结温为54.6 ℃,所有芯片均满足一级降额要求,发生锁定后AFE芯片没有烧毁风险。

综上所述,激光单粒子锁定防护试验表明,发生单粒子锁定时AFE芯片及其周围电路不会发生损坏且无烧毁风险,但模拟供电端限流电阻的功率将达到0.7 W,高于1206封装电阻的额定功耗。为防止出现在轨锁定时限流电阻过流烧毁、起不到保护作用的情况,工程设计时将模拟供电端限流电阻更换成相同阻值的1 W额定功率片式膜固定电阻器,确保防闩锁限流电阻如果发生锁定后不被烧毁,以保障模拟前端芯片工作正常。

-

多角度偏振成像仪在轨期间遭遇的空间高能粒子将诱发电子器件产生单粒子效应。重离子辐照试验结果表明,多角度偏振成像仪选用的模拟前端信号处理器对重离子诱发的单粒子效应比较敏感,单粒子锁定LET阈值处于4.4~13.4 MeV·cm2·mg−1之间。脉冲激光单粒子防护试验结果表明,当模拟前端发生锁定并且锁定状态维持95 min后,芯片没有出现烧毁,模拟端锁定电流为510 mA,数字端锁定电流为11 mA。对模拟前端进行断电重启,寄存器通讯和图像转换恢复正常,芯片恢复正常工作。针对模拟前端芯片LET阈值偏低的状态,采取模拟供电端和数字供电端串联大功率防闩锁限流电阻和在轨定时开关机的防护措施,可有效避免器件单粒子锁定造成的器件过流烧毁及仪器失效等故障。目前该防护措施已经应用于CM、GF(02)、DQ等多个卫星型号的偏振相机载荷中,这些型号的DPC载荷处于正样研制阶段,等待卫星发射后可通过在轨观测数据以验证单粒子防护措施的有效性。研究结果可为星载偏振遥感相机用模拟前端信号处理器单粒子效应危害评估和AFE电路加固设计提供重要参考。

DownLoad:

DownLoad: