-

近年来,随着商业航天及相关产业技术的发展,为卫星提供轨道维持,姿态调整动力的关键技术——空间推进技术也得到了迅猛发展[1-3]。当前,空间推进技术主要包括冷气推进、化学推进、电推进三大领域[4-6],而激光烧蚀推进技术相对而言具有体积小,冲量元小,控制精度高,比冲高等优点[7-8]。

影响激光烧蚀推进性能的因素有很多,主要包含激光器参数,烧蚀工质及烧蚀效果(靶坑大小,光斑形貌等)。其中不同材料的激光烧蚀推进性能是激光推进技术研究的热点,金属材料因其高比冲的推进性能特性备受关注。以金属作为工质,受到高能激光辐照后,金属熔融汽化,形成高速反喷羽流(主要成分为金属蒸气,等离子体)产生推力。Pakhomov A V等[9]对各种金属进行激光烧蚀试验发现:冲量耦合系数随原子量增加而增加,比冲则相反,认为中等原子量的靶材可以兼顾比冲和冲量耦合系数。其中金属铝作为烧蚀工质得到的比冲最高,可达4 000 s; 窦志国等[10]对大量金属材料烧蚀性能进行了对比分析,提出了根据推进剂的物理性能进行优选的方法,认为铜、铁、锌是比较好的金属推进剂。Phipps[11]通过研究激光脉宽对推进性能的影响发现,当激光脉宽小于纳秒量级时,激光能量密度较高,热传导效应微弱,任何类型的工质都可达到烧蚀阈值形成推力,使用金属工质可以得到极高的的比冲。对PVC:C,GLYN:C,GAP:IR. GAP:C,Au等五种材料进行推进性能测试。结果发现,相同实验条件下,烧蚀Au的比冲最高,可达3660 s。

与聚合物和含能工质相比,金属工质受高能激光作用后的离化率高,拥有更高的比冲。国内外许多学者已经对Al,Cu,Ni,Fe等金属进行了激光烧蚀的推进性能测试[12-13]。高激光功率密度(

${10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 量级)下的冲量、比冲等推进性能的实验研究不够全面,研究条件不够统一,性能的对比分析不具有对比性。文中使用纳秒脉宽激光对Al,Cu,Ni,Fe,Y,Au,Ag进行了重复烧蚀实验,测得七种金属材料在不同的激光功率密度下的冲量、烧蚀质量、冲量耦合系数、比冲、能量转化效率等推进性能参数,结合金属的电离能、熔沸点、电阻率等物理性质对金属材料在纳秒脉宽激光作用下的推进性能进行了对比分析,所获得的金属材料激光烧蚀性能规律为空间激光推进工质材料的选择提供了参考。 -

激光烧蚀推进性能的三个主要参数是冲量

$I$ ,冲量耦合系数${C_m}$ 和比冲${I_{sp}}$ 。冲量耦合系数

${C_m}$ 是激光烧蚀工质过程中将入射激光能量转化为冲量的能力,它与冲量$I$ 和入射激光能量$E$ 的关系为:式中:

$\Delta m$ 为烧蚀质量;$\nu $ 为羽流喷射速度;$E$ 为入射激光能量。比冲${I_{sp}}$ 是工质在激光烧蚀推进过程中,可以提供冲量的能力,和烧蚀量与冲量相关:${C_m}$ 和${I_{sp}}$ 都是冲量$I$ 的复合量,入射激光能量$E$ 、工质烧蚀质量$\Delta m$ 等都可以通过实验仪器直接测量得到。所以冲量$I$ 的测量是最为关键的。冲量

$I$ 为激光烧蚀过程中喷射的等离子体等,所产生的反作用力对时间的积分。冲量的测量通常利用摆的力学效应进行测量,常用的μN量级推力测量系统有扭摆型,单摆型,悬臂型[14]。文中采用可有效分离推力器重力和推力,灵敏度、信噪比调节简单的扭摆系统对冲量进行间接测量。扭摆横梁受到微推力作用后致使挠性枢轴会产生微小转动,通过位移传感器可测得冲量加载后第一次摆动的最大线位移。根据以上测量原理[15],可得冲量$I$ 的计算公式:式中:

$k$ 为扭摆的扭转刚度系数;${l_1}$ 为位移传感器与挠性枢轴的距离(测量臂);${l_2}$ 为脉冲激光烧蚀作用点与挠性枢轴的距离(力臂);${\omega _n}$ 为扭摆横梁角频率;$s$ 为冲量加载后第一次摆动的最大线位移;$k$ ,${l_1}$ ,${l_2}$ 均为系统参数。所以,冲量$I$ 与最大线位移$s$ 间的线性系数$A = \dfrac{k}{{{l_1}{l_2}{\omega _n}}}$ 可通过标定获得[16]。 -

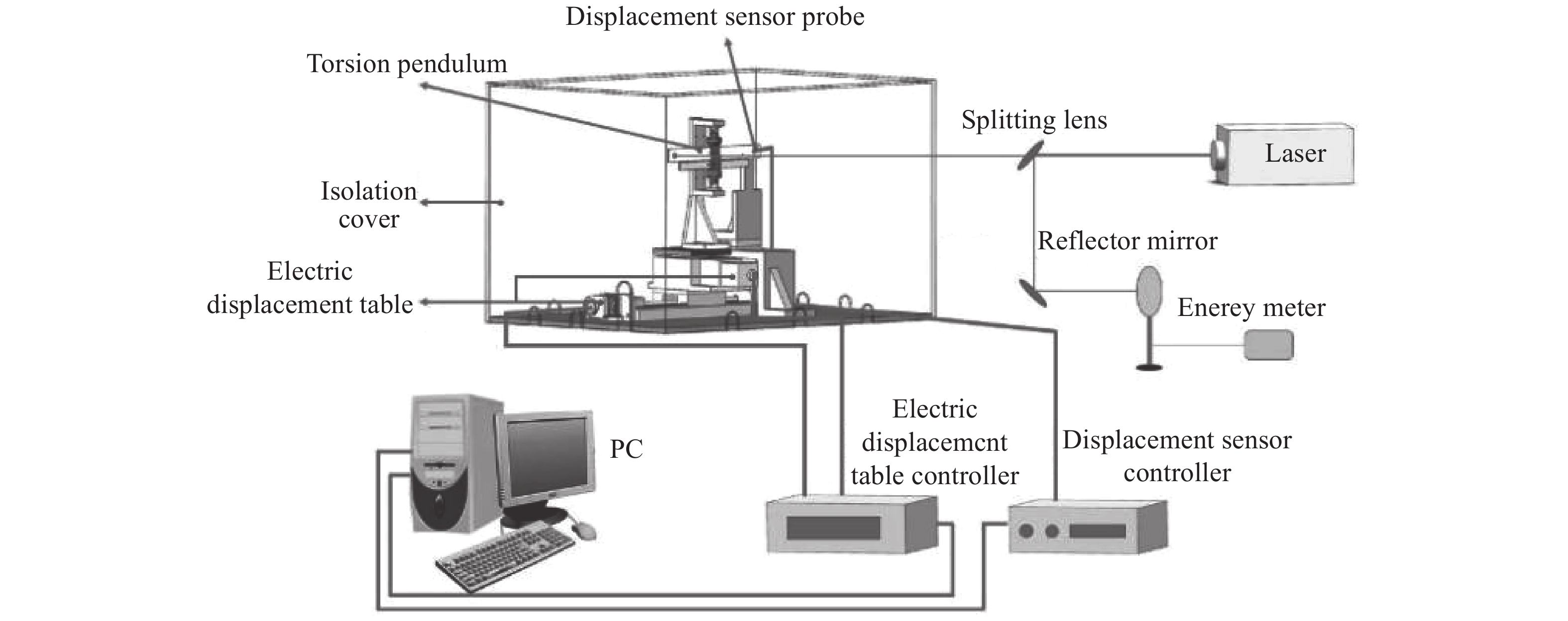

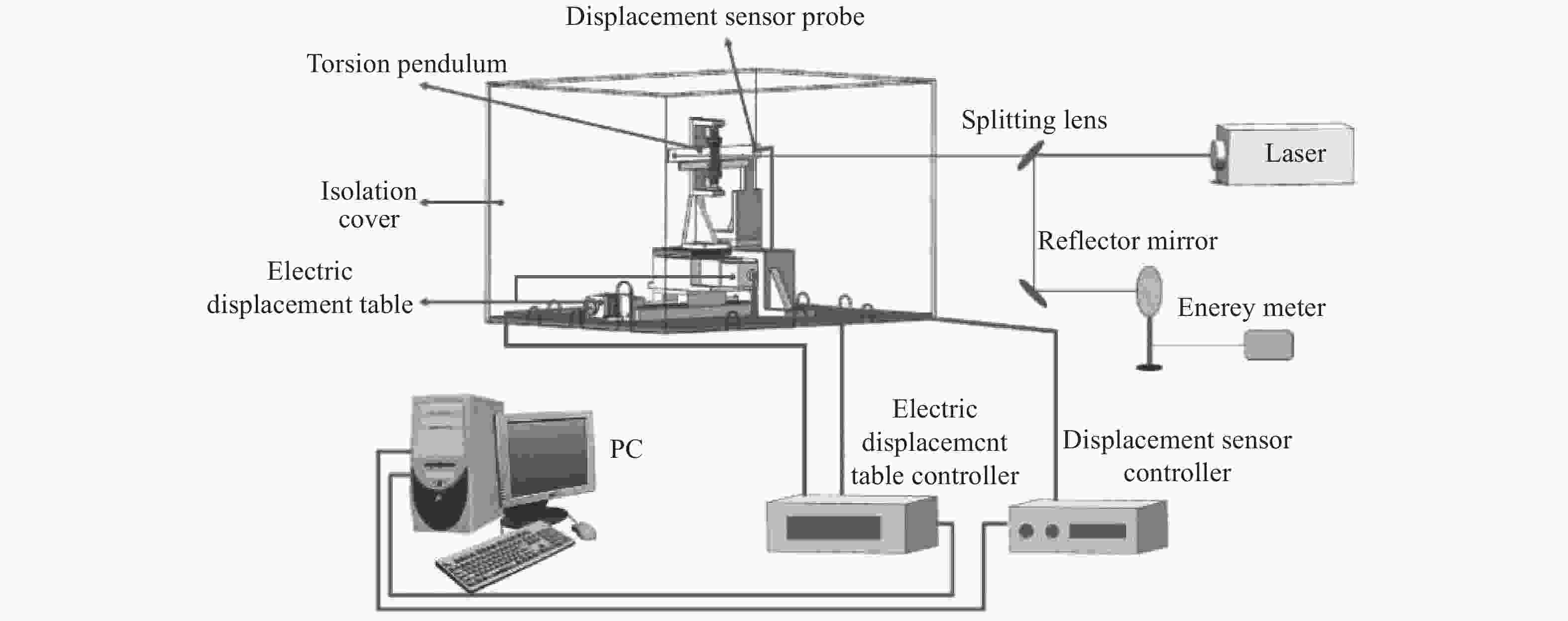

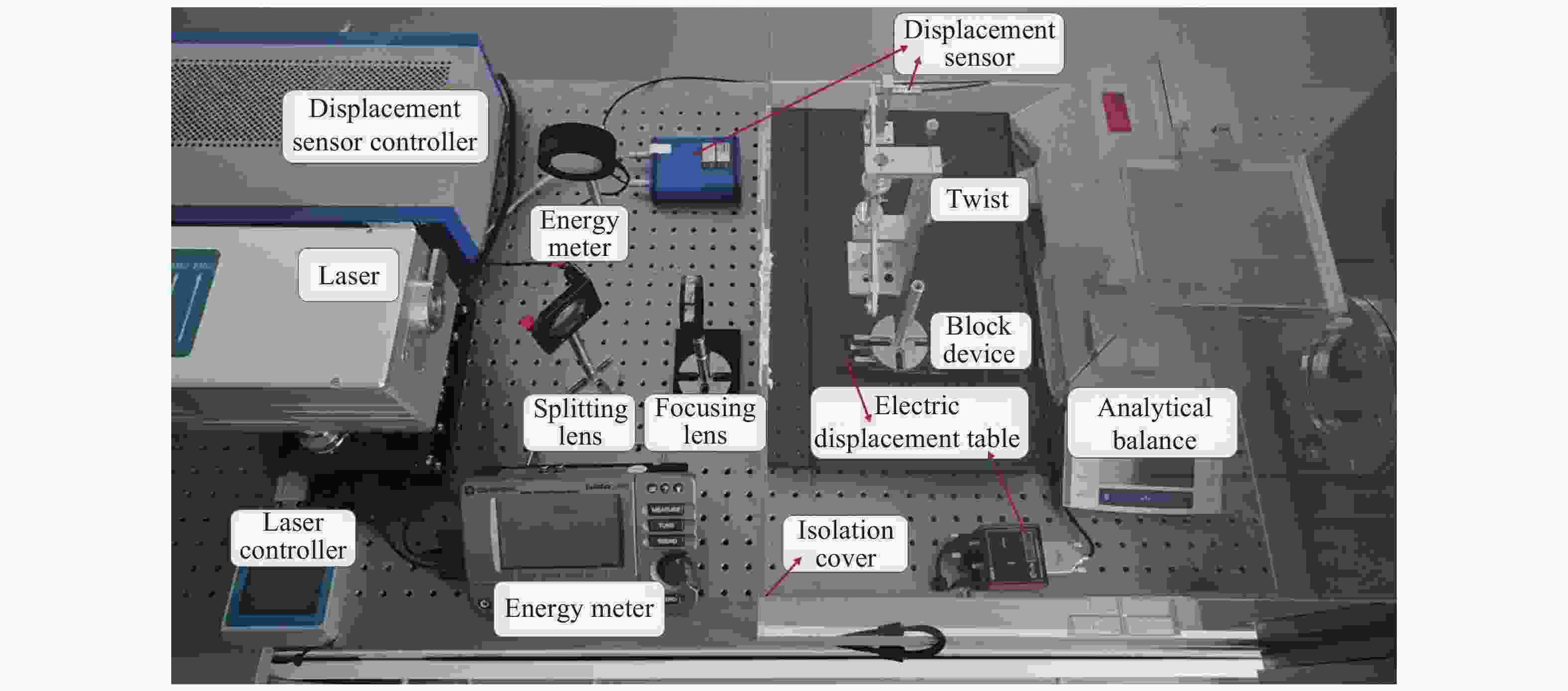

实验装置示意图如图1所示,由激光器、冲量测量扭摆、隔离罩等部分组成。

实验中采用单脉冲能量最高

$40{\rm{0}}$ mJ,波长$1\;064$ nm,脉宽为$10$ ns的Nd:YAG激光器作为能量源,最高功率密度可达${\rm{1}}{{\rm{0}}^{{\rm{10}}}}\;{\rm{W}}{\rm{/}}{\rm{c}}{{\rm{m}}^2}$ ,最小光斑直径约为200 µm。冲量测量扭摆主要由枢轴、测量横梁、位移传感器、扭摆支架等构成。扭摆的刚度系数

$k$ =0.0 096 N/m,测量臂${l_1}$ =100 mm,力臂${l_2}$ =110 mm,最大摆角$\theta {\rm{ = 5}}^\circ $ 。根据以上参数及位移传感器测量精度,通过标定得可测量范围在0.4~335 μ$ {\rm{N}} \cdot {\rm{s}}$ 的单脉冲冲量[17]。 -

实验靶材为直径

$10$ mm,厚$5$ mm的圆形纯金属靶材,纯度大于$99.9 $ %。对靶材进行独立重复烧蚀实验,烧蚀靶坑的间距(即电动位移台步长)为$300\;$ μm。 -

采用Nd:YAG激光器输出的能量范围在20~150 mJ的五种不同激光对七种金属材料进行辐照。图2中,激光通过分束镜后,一束激光通过透镜聚焦后作用于扭摆测量横梁上的金属靶材,通过位移传感器测得的线位移

$s$ 可求得冲量$I$ ;另一束通过能量计测量激光能量$E$ 。如表1所示,所选的七种金属材料的熔沸点及第一电离能各不相同,这会直接导致在相同的激光功率密度下,不同金属材料的推进性能参数不同。

Metal Melting

point/℃Boiling

point/℃First ionization energy/

kJ·mol−1Fe 1 535 2 750 762.5 Al 660 2 500 577.5 Cu 1 083 2 580 745.5 Ni 1 453 2 732 737.1 Au 1 062 2 966 890.1 Ag 961 2 210 731.0 Y 1 522 3 338 600.0 Table 1. Melting boiling point and the first ionization energy of seven metal materials

为了更准确地测得单个激光脉冲作用金属材料后的推进性能参数,在实验中,相同激光功率密度下,对不同金属材料均进行了多次重复烧蚀实验,通过图2中的分析天平,使用平均质量法[18]测得烧蚀质量

$\Delta m$ 。 -

图3为在不同激光功率密度下,金属的单脉冲烧蚀质量。整体来看,Fe的单脉冲烧蚀质量最大,且随激光功率密度的增大,单脉冲烧蚀质量增大的趋势较为明显;Y的单脉冲烧蚀质量最小,且随激光功率密度增大,单脉冲烧蚀质量增大的趋势较为缓和。除Fe之外,金属Ni,Al和Cu的单脉冲烧蚀质量均达到

${10^{ - 9}}$ kg的量级,烧蚀效果较好。在短脉冲激光辐照下,金属的质量迁移主要为浅层气化机制。而金属的熔化、气化等相变过程与其对激光的吸收率直接相关。公式(4)为Hagen-Ruben公式,可计算金属对波长1 064 nm激光的吸收率[13]:

式中:

$A$ 为吸收率;$\;\rho $ 为电阻率;$T$ 为温度;由上式可知,金属的电阻率越大,它对波长1 064 nm激光的吸收率越高。表2为

$20$ ℃时,七种金属材料的电阻率。Metal Fe Al Cu Ni Au Ag Y Resistivity 9.7 2.7 1.7 6.8 2.4 1.6 59.6 Table 2. Resistivity of seven metal materials (Unit: 10−8 Ω·m,20 ℃)

由此可知,Y的电阻率最高,但由于Y的沸点为

$3\;338$ ℃,导致Y的单脉冲烧蚀质量并不是最大,反而是七种金属材料中最小的;Fe,Ni,Al的沸点相近,均在$2\;500\sim 2\;750$ ℃的范围内,但Fe的电阻率最高,所以它对激光的吸收率最高,单脉冲烧蚀质量最大。 -

金属在大气下受到高能激光的辐照,发生气化和质量迁移,形成的靶蒸气、等离子体的喷射膨胀及金属表面环境气体中的LSD波(LSD是激光维持的爆轰波)对靶表面施加反冲压力,作用于靶的压力脉冲(激光脉冲)很短,其宏观力学效应可以用冲量表征[19]。

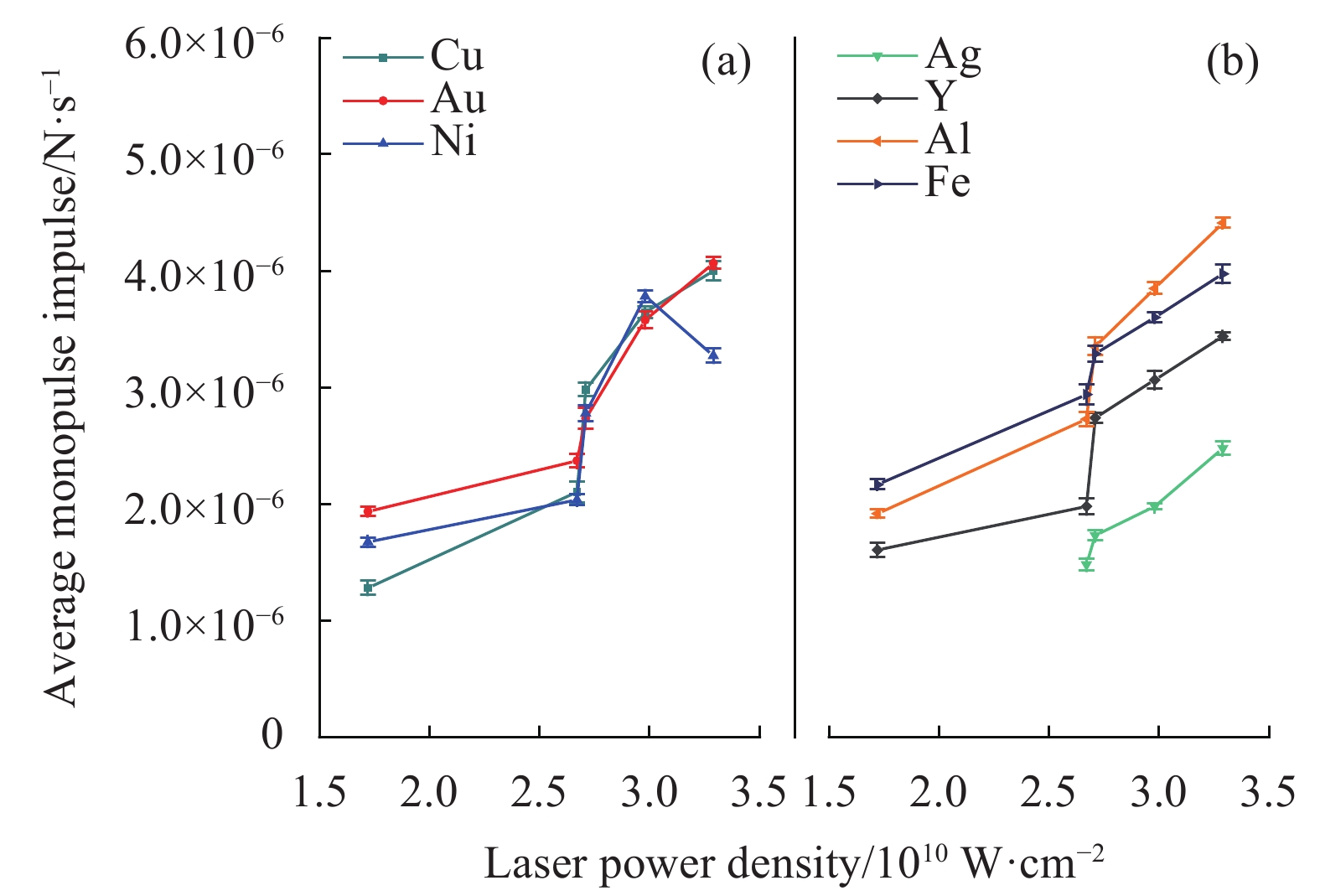

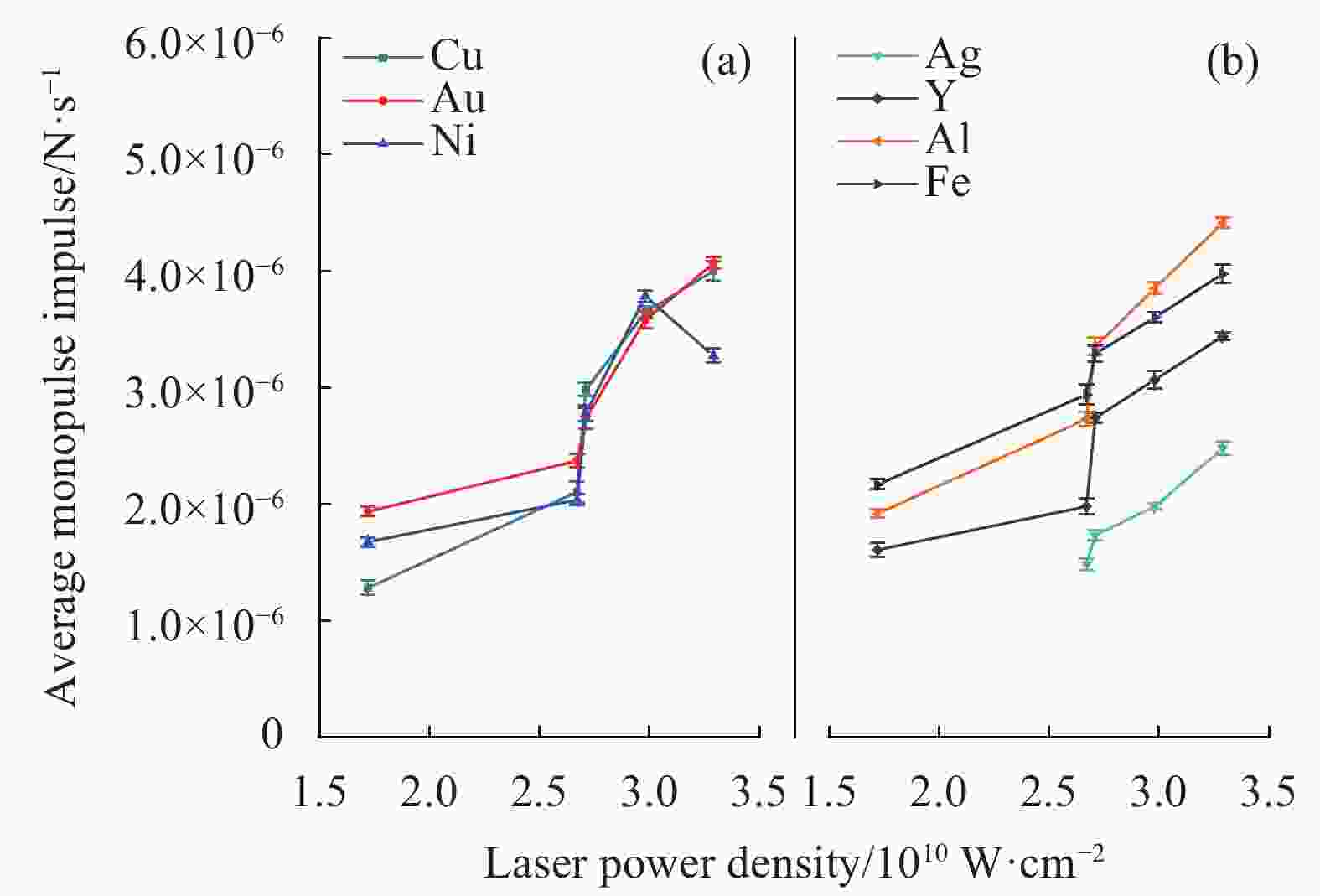

图4为在不同激光功率密度下,金属材料的单脉冲冲量。由此可以看出,七种金属材料的单脉冲冲量随激光功率密度的增加而增加。Au的单脉冲冲量最大,在激光功率密度为

$3.29 \times {10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 时,最高单脉冲冲量达4 μN·s。随着激光功率密度增加而增大的趋势也最为显著。Fe和Ni的单脉冲冲量居中。由表1,表2可知Y的沸点(

$3\;338\; $ ℃)在七种金属材料中最高;Ag的电阻率在七种金属中最低,仅有$1.6 \times {10^{ - 8}}\;\Omega \cdot {\rm{m}}$ ,其对激光的吸收率最低。所以这两种金属材料相较而言难形成靶蒸气、等离子体的喷射及LSD波,所以Y和Ag的平均单脉冲冲量相对较差。由于大气对激光的衰减以及等离子屏蔽等效应,导致实验整体冲量数据偏小。 -

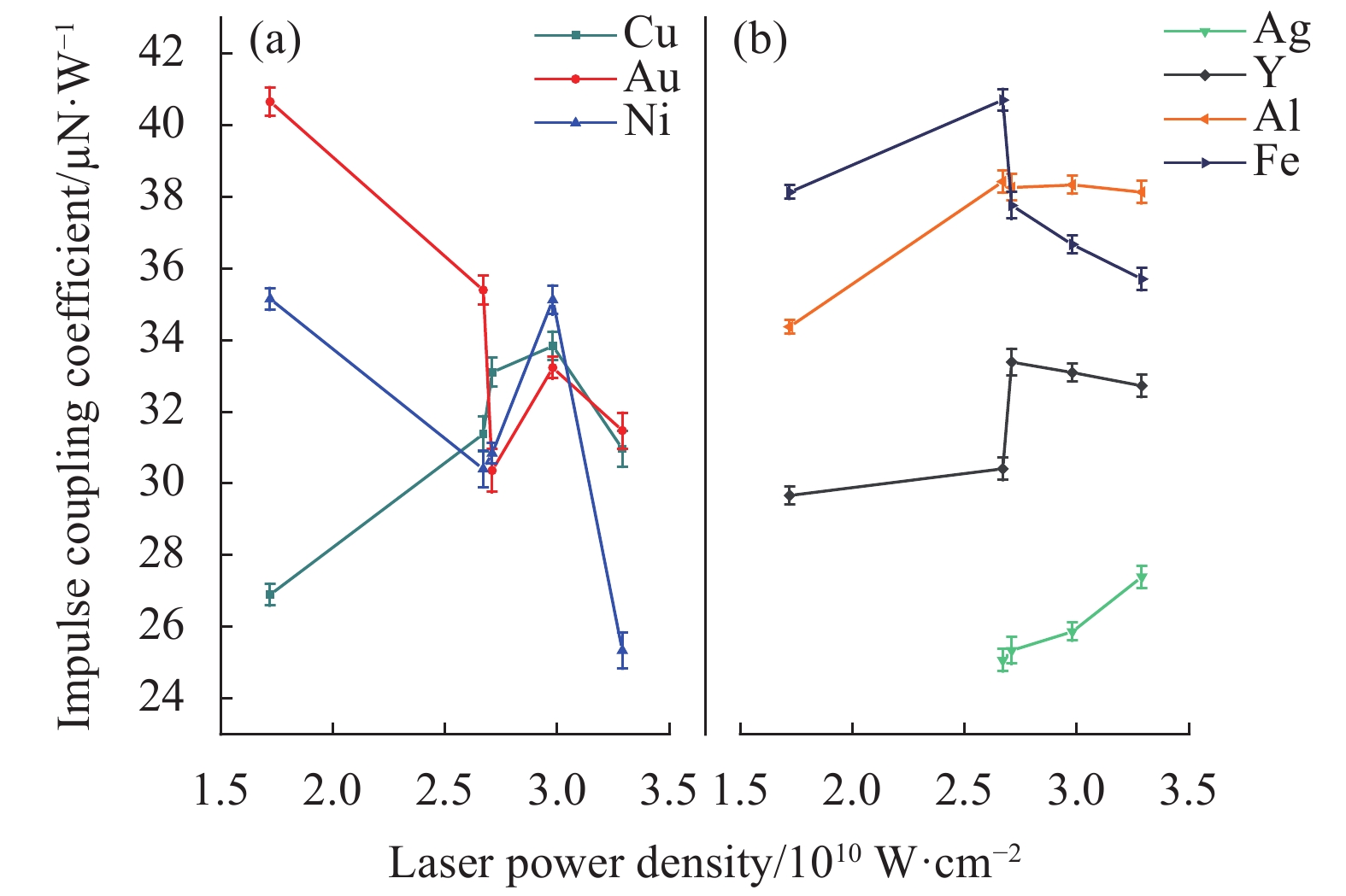

图5为不同激光功率密度下,激光烧蚀金属材料的冲量耦合系数。由图中可看出,除Au外,其它六种金属材料的冲量耦合系数均有随激光功率密度增大先增加后减少的趋势,说明在实验过程中产生了等离子体屏蔽效应,这与文明等[20]所得的实验结果一致。

Cu,Au,Ni,Al,Fe五种金属材料的冲量耦合系数均值都在30 μN/W以上。Au的冲量耦合系数最大,在入射激光功率密度为

$1.72 \times {10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 时达到最高值40.7 μN/W。Ag是七种金属材料中冲量耦合系数最小的。图6为不同激光功率密度下,激光烧蚀金属材料的比冲。大气条件下,激光能量会有衰减,以及等离子体屏蔽效应,致使冲量偏低,导致比冲数据偏低。

实验中,七种金属材料的比冲均在100 s以上。Au的比冲相对较高,最高的比冲可达500 s左右,但是比冲受激光功率密度的变化影响较大。Al,Cu,Ni的比冲受激光功率密度的变化影响较小,平均比冲可达200 s以上。Fe和Ag在实验中的比冲相对较低。

-

文中在大气条件下,采用波长1064 nm,10 ns脉宽的Nd:YAG激光器,在不同激光功率密度下对Al,Fe,Ni,Cu,Y,Ag,Au七种金属材料进行激光烧蚀推进性能的测试实验,得到它们的单脉冲烧蚀质量,平均单脉冲冲量,冲量耦合系数和比冲等四个推进性能参数。大气条件下,激光功率密度在

$1.72 \times {10^{10}}\sim 3.29 \times $ $ {10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 范围内: -

表3为七种金属材料的平均单脉冲烧蚀质量与冲量。相同功率密度下,Fe的平均单脉冲烧蚀质量最大,约为1.6 μg。Cu, Al, Ni, Ag,Au, Y的平均单脉冲烧蚀量依次减小。Al,Fe,Ni三种金属材料的平均单脉冲冲量均值在2.5 μN·s左右,Y和Ag的平均单脉冲冲量相对较差。

Metal Al Fe Ni Cu Y Ag Au $\overline {\Delta m} $ 0.7 1.6 0.5 1.3 0.2 0.7 0.4 $\overline I $ 2.5 2.5 2.5 2.8 1.8 1.2 2.7 Table 3. Average monopulse ablation mass (μg)and impulse (μN·s)

由3.1及3.2分析可知,吸收率及熔沸点是影响激光烧蚀推进性能的重要因素。金属对激光的吸收率大,熔沸点低,其激光烧蚀阈值较低,进而会导致烧蚀质量较大,同时也会影响冲量的大小。

-

冲量耦合系数是激光烧蚀靶材产生的冲量与入射激光能量的比值。激光辐照金属的过程中,随着脉冲时间及激光功率密度的增加,靶蒸气被电离,产生等离子体屏蔽效应,进而导致了冲量耦合系数的下降。在3.3节中提到,Au的冲量耦合系数并没有出现随激光功率密度的增大先增大后减小的现象,对Au的冲量耦合系数数据采用Phipps提出的以

$E\lambda \sqrt {{t_p}} $ 为变元的流体力学为主导机制的烧蚀定标关系[19]进行拟合:式中:

$\lambda $ 为激光波长;${t_p}$ 为激光脉宽;得到的拟合关系如图7所示。

由图7可看出,在Phipps提出的烧蚀定标关系下,Au的冲量耦合系数是会随着激光功率密度增大而减小。

-

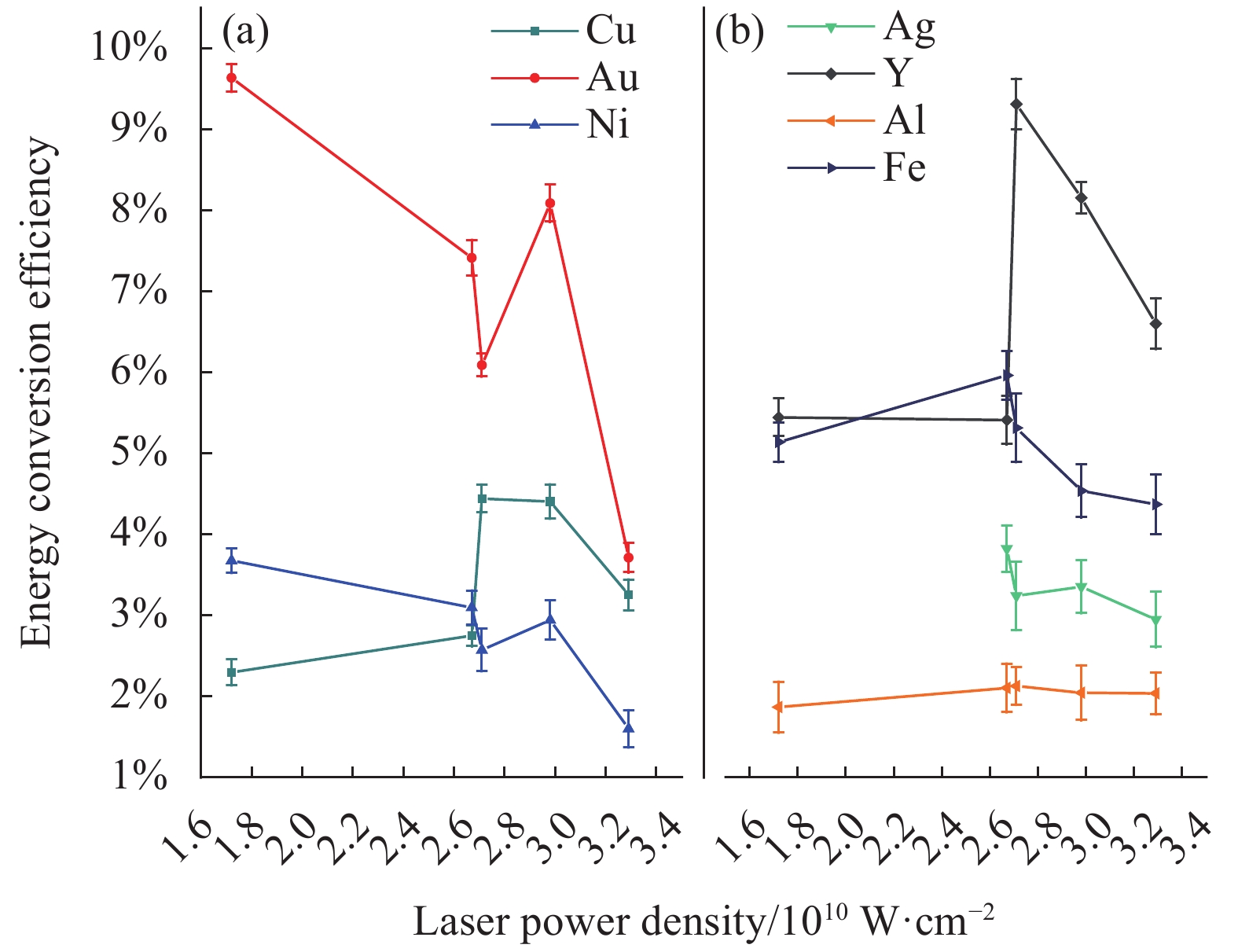

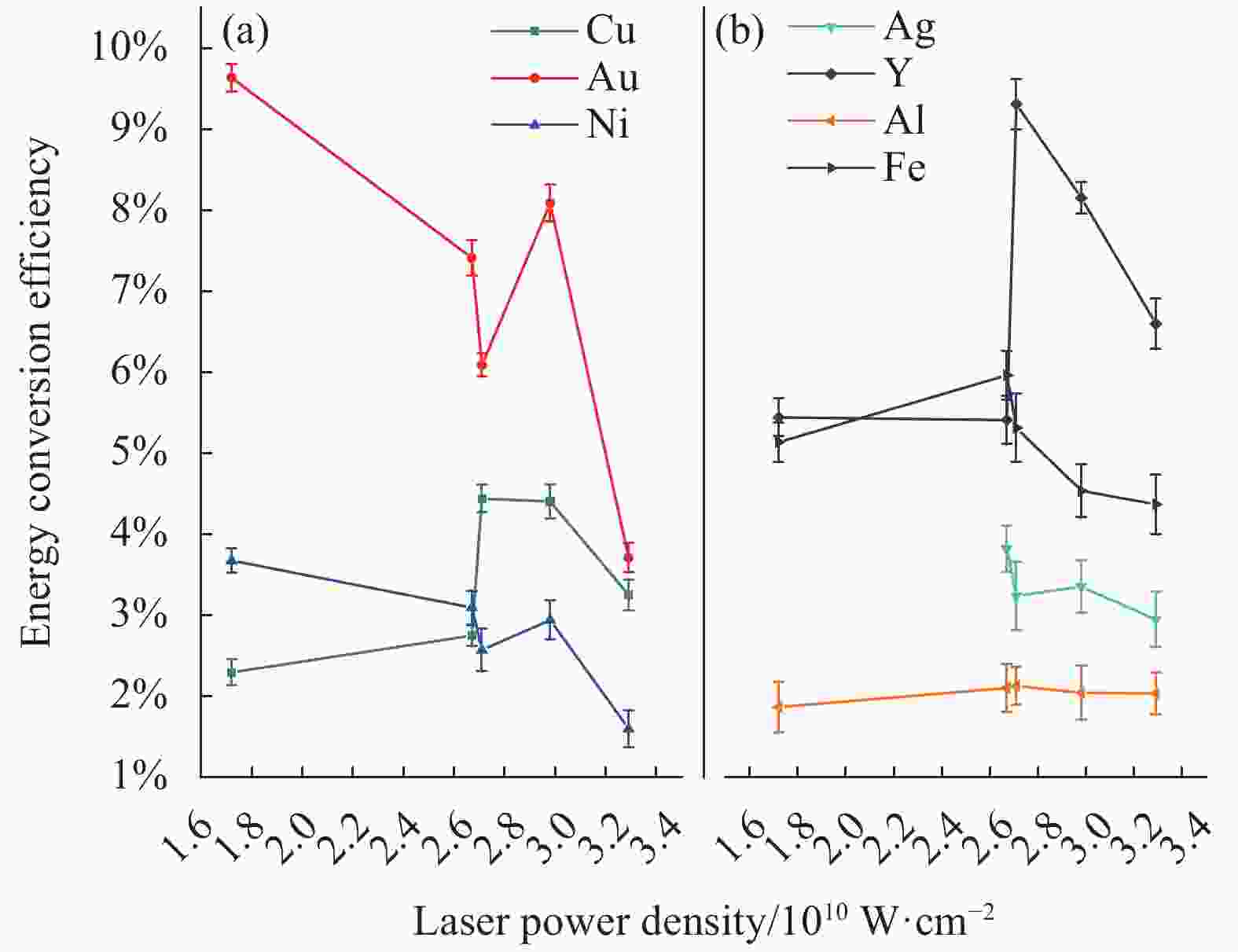

七种金属材料的比冲均在100 s以上,根据七种金属材料的比冲和冲量耦合系数可以计算激光烧蚀金属材料的能量转化效率:

式中:g=9.8 m/

${{\rm{s}}^2}$ 。得到七种金属材料在不同激光功率密度下的能量转化效率如图8所示。

整体而言,激光烧蚀金属的能量转化效率在10%以下。Au的能量转化效率在七种金属材料中最高,平均能量转化效率可达6%以上,Ag的能量转化效率最低。

-

文中在大气条件下进行了高能脉冲激光烧蚀Al,Fe,Ni,Cu,Y,Ag,Au七种金属材料的推进性能实验研究,分析了单脉冲烧蚀质量,单脉冲冲量,冲量耦合系数,比冲,能量转化效率等性能参数,结果表明:相同激光功率密度下,Au的激光烧蚀推进性能最优。在入射激光功率密度为

$1.72 \times {10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 时,冲量耦合系数的最高值达40.7 μN/W;在入射激光功率密度为${\rm{2}}{\rm{.98}} \times {10^{10}}\;{\rm{W}}/{\rm{c}}{{\rm{m}}^2}$ 时,比冲的最高值达500 s;平均能量转化效率在6%以上。

Experimental study on propulsive performance of typical metal ablated by nanosecond pulse width laser

doi: 10.3788/IRLA20210277

- Received Date: 2021-04-25

- Rev Recd Date: 2021-06-20

- Publish Date: 2021-11-02

-

Key words:

- space propulsion /

- laser ablation /

- impulse coupling coefficient /

- specific impulse

Abstract: In order to study the laser ablation propulsion performance of different metal materials, an Nd:YAG laser with a wavelength of 1064 nm and a pulse width of 8 ns was used to ablate seven common metal materials: Al, Fe, Ni, Cu, Y, Ag and Au in the atmosphere. Propulsion performance parameters such as ablation mass, impulse, impulse coupling coefficient, specific impulse and energy conversion efficiency were measured, and the influence law of laser power density on propulsion performance was obtained. The experimental results show that under the same laser power density, the ablation amount of Fe is the largest, the ablation amount of Y is the smallest. The impulse of Al, Au and Cu is larger, while that of Ag is the least. Au's impulse coupling coefficient and specific impulse mean value are the largest among the seven metals, reaching the maximum value of 40.7 μN/W and 500 s when the laser power density is

DownLoad:

DownLoad: