-

铝合金材料由于其质地轻柔且强度高,在交通、海洋、航天等领域轻量化部件中具有极高的应用性。铝土矿是铝合金生产过程中的主要原材料,因此快速、高精度检测铝土矿成分含量,对铝及铝合金的生产显得尤为重要,对促进我国铝土矿开发、铝工业发展具有重大意义。

激光诱导击穿光谱(laser-induced breakdown spectroscopy, LIBS)技术在最近几年发展迅速,是一种新型的原子发射光谱检测技术,它利用脉冲能量将激光聚焦于样品表面,样品表面吸收能量后快速升温产生等离子体,等离子体在冷却降温的过程中产生原子发射光谱,根据光谱强度大小实现待测样品中元素含量的检测[1-4]。LIBS操作简单、几乎对样品没有损耗,便于被用于光谱辐射信息对多物态材料[5-7]元素成分含量及种类进行研究,因此,LIBS被广泛应用在矿物勘测[8-9]、生物制药[10-11]、冶金行业[12-13]等领域中。

为了改进传统LIBS存在的灵敏度低、特征谱线噪声较大等缺点,国内外研究学者提出利用多种辅助约束的方法来增强LIBS光谱强度,提高信噪比。Wang等[14]研究了激光脉冲能量及放电通道对火花放电辅助的LIBS影响,确定了LA-SIBS在检测铝合金、黄铜等样品下的最优实验条件,降低了元素的检出限。于丹等[15]研究了加热样品结合空间约束LIBS的方法对光谱强度的影响,他们发现样品温度升高时,光谱强度也会随着升高,当两种外部条件共同作用时LIBS收集到光谱的增强效果最好,在此条件下Al Ⅰ 396.2 nm谱线强度增大了2.1倍。李业秋等[16]人利用双脉冲DP-LIBS技术对大气中的重金属成分进行分析,并探讨了脉冲间隔对双脉冲激光所激发的谱线强度的影响,实验结果表明:双脉冲激光可以有效增强光谱强度,同时谱线的稳定性也得到了一定的提高。Minchao Cui[17]利用长-短双脉冲激光诱导击穿光谱(DP-LIBS)对钢铁样品中的锰元素进行了定量分析,结果表明:与单脉冲LIBS相比,DP-LIBS拟合系数R2从0.810提升到0.988,且平均预测相对误差也从29.3%下降到10.5%。

文中通过激光诱导击穿光谱系统结合外加腔体约束对铝土矿中Si、Al元素光谱强度进行研究,通过分析特征谱线Si Ⅰ 288.15 nm及Al Ⅰ 308.21 nm的谱线强度及信噪比随实验参数的变化趋势,确定了铝土矿实验的最佳参数,并对所产生的现象进行相应的分析,为后续Si、Al元素含量检测奠定了基础。

-

文中采用高度3 mm,孔径4 mm的铝制柱形腔体对LIBS进行约束,将腔体放置于压片后的铝土矿表面,当激光对铝土矿样品进行烧蚀时,产生等离子体,等离子体产生的过程中,伴随着冲击波的产生,冲击波向外扩散,遇到腔体壁时会被反射,反射后的冲击波会进一步压缩等离子体,这样加剧了等离子体内部粒子的碰撞,进而使等离子体光谱强度增强。

-

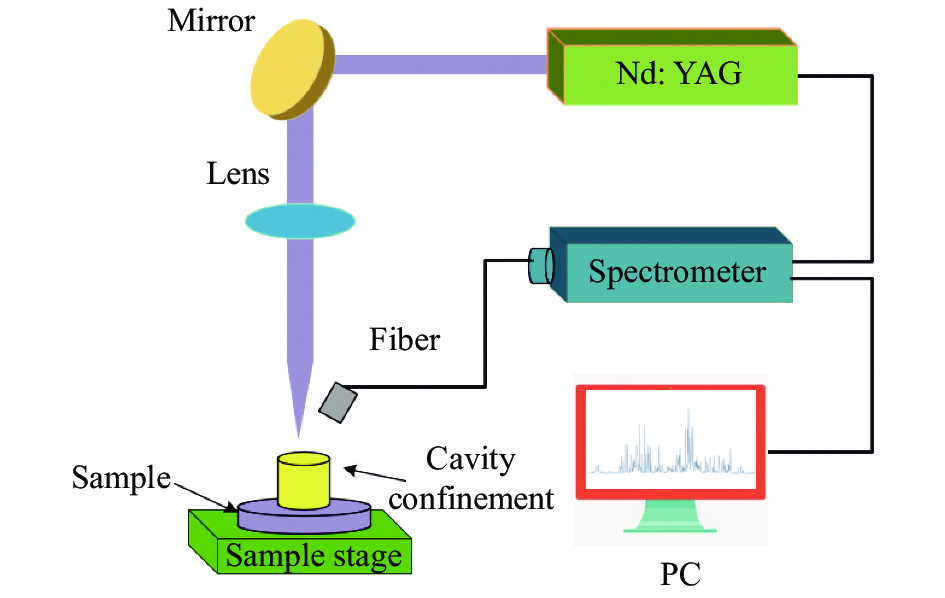

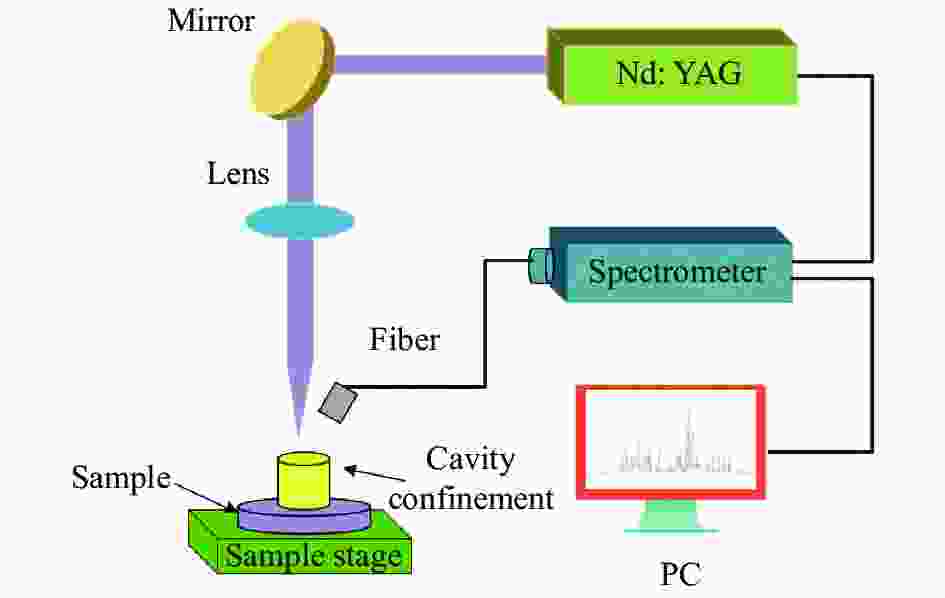

实验过程中用来检测铝土矿中成分的仪器来自美国TSI公司的ChemReval台式集成一体化的激光诱导击穿光谱仪,它包含激光器、光谱仪以及样品仓。激光器采用法国Quantel公司的Nd:YAG激光器,波长为1 064 nm,最大分析深度为100 μm,激光能量为0~200 mJ,重复频率为0~10 Hz。采集到的光谱范围为190~950 μm,在实验过程中,作为腔体约束的材料为厚度3 mm,孔径4 mm的铝制薄片,将其紧贴铝土矿样品表面,通过PC端对样品台进行控制,使激光聚焦在空腔中心。LIBS实验装置如图1所示, 实验场景图如图2所示。

-

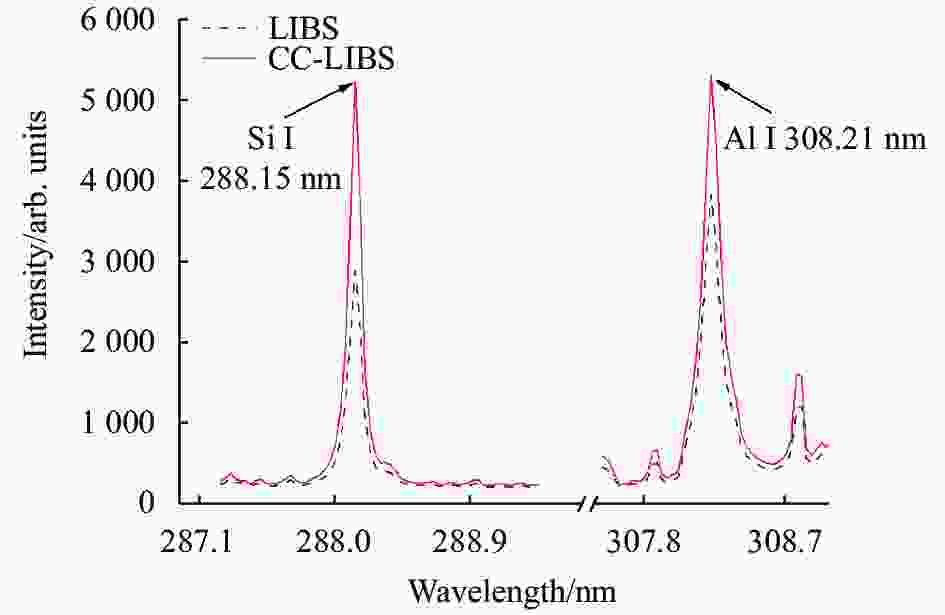

由于铝土矿中含有大量的硅杂质,硅杂质的存在使得铝及铝合金的生产过程变得复杂,且降低了铝土矿资源的品味,限制了铝合金行业的发展,因此需要重点检测铝土矿中的Si元素及Al元素。设置激光能量为70 mJ,激光脉冲重复频率为50 Hz,采集延迟时间为1 μs,收集到的Si元素及Al元素的特征谱线在传统LIBS与外加腔体约束LIBS条件下的光谱对比如图3所示。

从图3中可以看出,与传统LIBS相比,外加腔体约束下Si Ⅰ 288.15 nm以及Al Ⅰ 308.21 nm特征谱线强度得到了明显的增强,这是因为激光诱导铝土矿样品表面产生等离子体时,在激光烧蚀过程中同时也伴随着冲击波的产生,由于冲击波的运动速度要比等离子体的扩散速度快,因此冲击波比等离子体先碰触到腔体内壁,腔体壁的约束使得冲击波向等离子体扩散中心运动,导致等离子体的碰撞频率增大,实现特征光谱强度的增强。

-

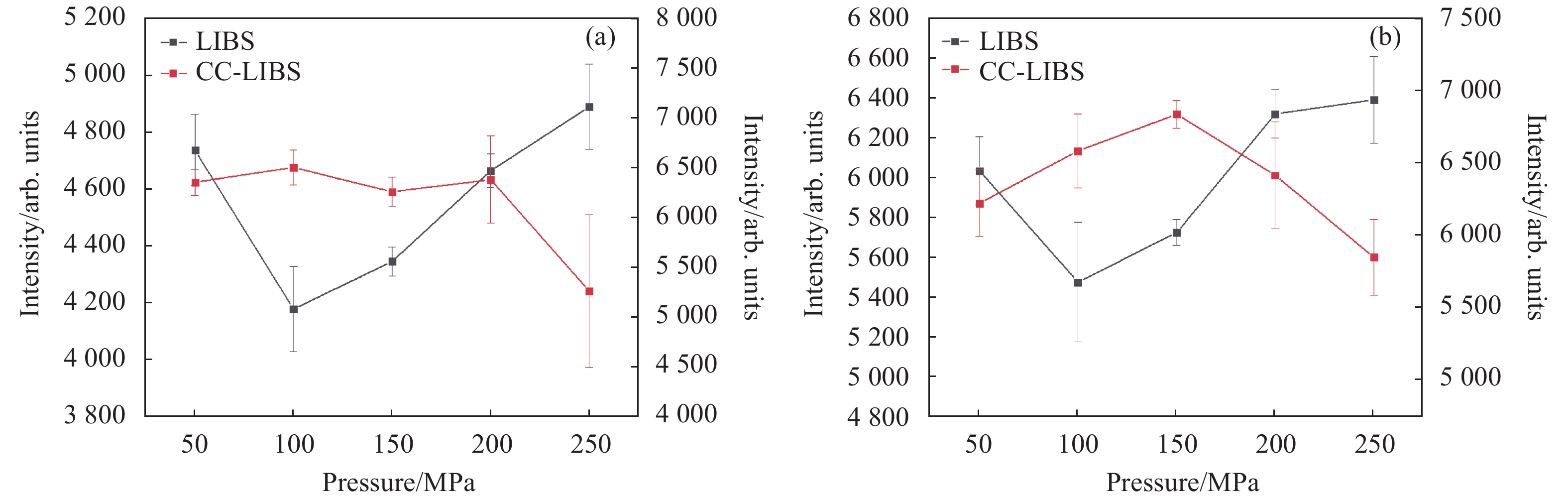

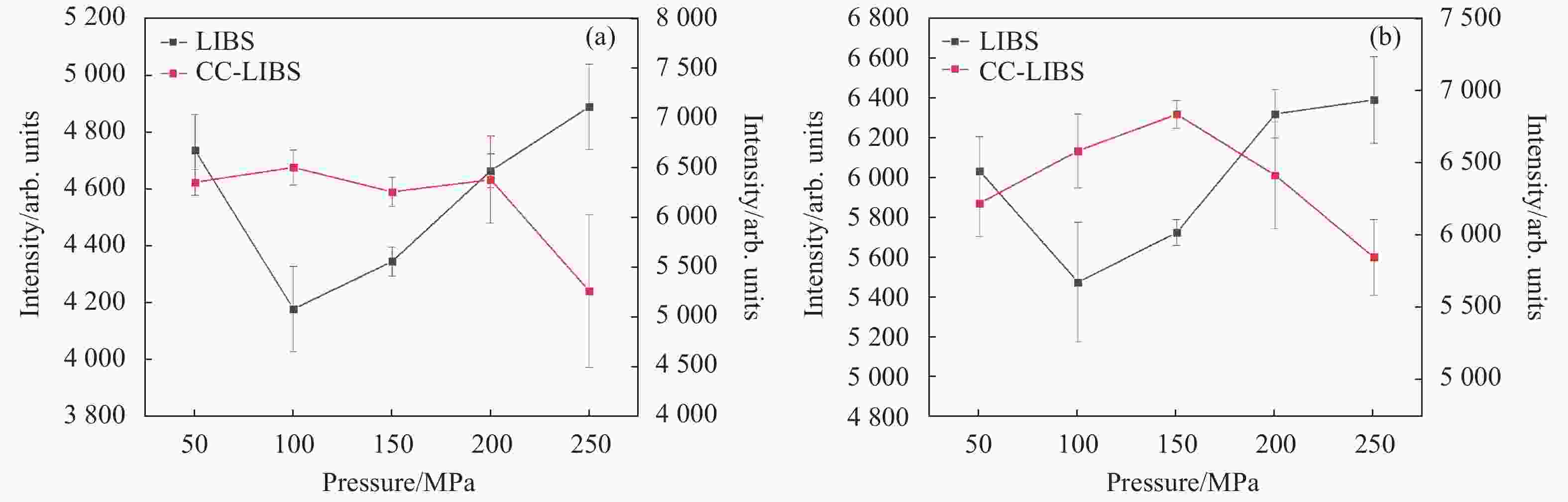

铝土矿样品在处理过程中利用压片机对粉末状的铝土矿进行压片,压片机的参数设置直接影响样品颗粒之间的疏松程度,当激光击打到样品表面时,则会对特征光谱强度造成一定的影响。在实验过程中,对粉状铝土矿样品研磨并过筛,筛目为100,设置压片机的压强大小为50 MPa、100 MPa、150 MPa、200 MPa和250 MPa,将铝土矿粉末压制成厚度为2 mm的薄片,每组光谱测量是15次激光脉冲作用的平均值。从图4可知,在不同压强下,Al、Si两种元素的特征谱线强度在一定范围内浮动,文中通过误差棒大小来反应谱线的稳定性,当压强为50 MPa、100 MPa、200 MPa和250 MPa时,所分析的两个特征谱线误差棒相对较大;当压强为150 MPa时,误差棒较小,即收集到的光谱强度较为稳定,因此在后续制备样品时,选择压强为150 MPa作为压制铝土矿样品的最优压强参数条件。

Figure 4. Spectral line intensity of Al and Si elements under different pressures. (a) Si Ⅰ 288.15 nm; (b) Al Ⅰ 308.21 nm

压强对铝土矿激光诱导击穿光谱的影响主要是影响其光谱稳定性,用压片机制备铝土矿样本时,当压强较小时,铝土矿样品表面会相对疏散,激光烧蚀样品时会出现样品飞溅或烧蚀不充分等,这样会导致激光诱导击穿光谱不太稳定;当样品较大时,又会出现样品破裂,因此针对不同的样品,选择合适的压强进行样品制备,能很好地提高样品稳定性。

-

LIBS谱线强度的大小与激光能量大小有关,同时信噪比(Signal-ratio, SNR)作为评估LIBS灵敏度的方法被广泛用于LIBS实验最优条件的选取中。为了测量不同激光能量下对Si、Al等离子体发射光谱的影响,设置激光能量为40~100 mJ之间,分析Si Ⅰ 288.15 nm及Al Ⅰ 308.21 nm的特征谱线,得出激光能量对光谱强度及SNR的影响,结果如图5、图6所示。从图5(a)、图5(b)中可以看出,无约束LIBS和外加腔体约束LIBS条件下,特征谱线强度随激光能量的增大而增大。由图6(a)和图6(b)可知,激光能量设置在40~80 mJ之间时,特征谱线的信噪比呈现单调递增的状态,当激光能量继续增大时,特征谱线处的SNR开始下降并趋于平缓,且与无约束条件相比,外加腔体约束下Si、Al元素特征谱线SNR都得到了一定的增强。激光能量为80 mJ时,Al、Si特征谱线在外加腔体约束条件下的SNR达到最大,为文中实验的最佳激光能量参数。

Figure 5. Spectral intensities of Al and Si elements change with laser energy under two LIBS conditions. (a) LIBS; (b) CC-LIBS

当激光能量较小时,铝土矿对应的烧蚀量相对少,光谱强度也相对弱,随着激光能量的增加,样品烧蚀量增加,光谱强度也随之增强;如图6所示,当激光能量增加到80 mJ时,铝、硅谱线信噪比SNR达到最大值,继续增加激光能量,信噪比SNR会略微下降,这是因为过大激光能量在增强特征光谱的同时,也导致了噪声辐射的增加,从而影响了光谱强度及其信噪比SNR。

-

激光烧蚀样品表面后会产生大量的等离子体,但由于等离子体会发生猛烈的膨胀,因此等离子体存在时间非常短暂,探究光谱仪采集延迟时间对特征光谱的影响也是十分必要的。设置LIBS激光能量为80 mJ,光谱仪采集延迟时间在0.5~5 μs之间递增。分析延迟时间对特征谱线强度及信噪比的影响,结果如图7、图8所示。图7(a)和图7(b)分别是未加腔体约束及外加铝薄片腔体约束LIBS条件下,Si、Al元素的光谱强度随延迟时间的变化。从图7中可以看出:当采集延迟时间为0.5 μs时,光谱强度最大,这是因为在0.5 μs处,等离子体中发光原子数量多,所以原子光谱强度大,但是辐射噪声也大,信噪比不是最佳。从图8(a)、图8(b)可知,SNR随采集延迟时间的增大呈现先增大后减小的现象,并在1 μs时SNR达到最大,因此选择延迟时间为1 μs作为文中实验的最优延迟时间。

Figure 7. Spectral intensities of Al and Si elements change with the acquisition delay time under two LIBS conditions. (a) LIBS; (b) CC-LIBS

Figure 8. SNR of Al and Si elements vary with the acquisition delay time. (a) Si Ⅰ 288.15 nm; (b) Al Ⅰ 308.21 nm

等离子体从产生到结束时间很短,等离子体产生初期,伴随着大量的背景辐射,这样直接影响人们对特征谱线的采集与分析。图中分析了光谱强度随采集延迟时间的变化情况,当采集延迟时间为0.5 μs时,光谱强度最大,然后随之减少,这是因为延迟时间到达0.5 μs时,特征谱线达到最大值,随着延迟时间的增加,部分特征谱线已逐渐衰减,相应的谱线强度也逐渐降低,结合信噪比参数,选定最优为1 μs。

-

文中研究了外加腔体约束LIBS、压片机压强变化、激光能量变化、光谱仪采集延迟时间对铝土矿中Si、Al元素特征光谱强度及信噪比的影响。实验结果表明:压片机压强的大小对样品的颗粒紧实度有一定的影响,进而影响光谱稳定性,当压强为150 MPa时,光谱稳定性最好;随着激光能量的增强,特征光谱强度增大,同时信噪比呈现先增大后减小的趋势,且在80 mJ时达到最大;当采集延迟逐渐增大时,光谱强度逐渐减小,且信噪比均为先增大后减小的趋势,当延迟时间在1 μs时,信噪比最大;与未加约束相比,腔体约束可以增强等离子体的光谱强度,同时信噪比也得到了一定的增强。文中针对铝土矿样品激光诱导击穿光谱实验条件进行了优化研究,相关结论适合铝土矿LIBS检测分析,在铝土矿定性定量检测领域具有一定的普适性。

Parameter optimization of laser-induced breakdown bauxite spectra based on cavity confinement

doi: 10.3788/IRLA20210661

- Received Date: 2021-09-13

- Rev Recd Date: 2021-11-12

- Accepted Date: 2021-11-17

- Publish Date: 2022-04-07

-

Key words:

- extern cavity constraint /

- LIBS /

- bauxite /

- SNR /

- delay time

Abstract: Based on the external cavity constraint method, the experimental parameters of laser induced breakdown spectroscopy (LIBS) of Al and Si in bauxite were optimized. By setting the pressure, laser energy, delay time and other parameters, traditional LIBS and external cavity constrained LIBS (CC-LIBS) were used to ablate bauxite samples. The optimal experimental conditions were analyzed by selecting SiⅠ288.15 nm and AlⅠ308.21 nm as the characteristic spectrum. The results show that: when the pressure is 150 MPa, the deviation of the spectral line intensity is the smallest; when the energy is 80 mJ, the collected characteristic spectral line SNR is the largest; when the delay time is 1 μs, the SNR obtained by the two elements of Al and Si is the best, the optimal experiment condition is determined. Compared with traditional LIBS, the characteristic spectral line intensity and SNR collected by CC-LIBS have been improved, which provides new experimental basis and ideas for the detection of Al and Si elements in bauxite and has certain reference value.

DownLoad:

DownLoad: