-

随着工业经济的发展,石油天然气已成为人们生活和生产过程中不可缺少的能源,其在运输、石化产品生产和使用过程中可能会发生泄漏。工业气体的泄漏不仅污染环境,处理不及时将会发生火灾、爆炸等灾害,造成生命财产的重大损失,成为当前工业生产和交通运输等领域的重大灾害之一。另外,碳排放也是当前国际性的重要话题。2021年,我国两会将“碳达峰”、“碳中和”写入政府工作报告[1],郑重向世界承诺具体时间和标准,其中甲烷排放作为重要的控制指标,也成为石油天然气化工行业重点控制排放的指标。因此,世界各国都非常重视快速有效的泄漏遥测或检测技术的研究和仪器研发[2]。2019年7月,国家应急管理部颁布了迫切需要有效防范化解石化生产、油气增储扩能带来的重大安全风险。

常见的工业危险气体红外特征吸收峰位置大多在红外波段[3]。传统的气体检测传感器属于接触式测量,虽然灵敏度和测量精度较高,一般可达到百万分之一(ppm, 1 ppm=10−6)量级浓度,但往往需要在一个区域布上成千上万个传感器,需要扫描每个潜在的泄漏点,耗时耗力。实践表明,单点探测器检测易受风向等环境因素影响,难以快速定位泄漏源或预测泄漏现场态势,其检测效率较低[4]。

近年来,工业气体泄漏红外成像检测技术得到迅速发展[5]。虽然红外成像检测技术灵敏度较传统单点气体传感器低,但其非接触成像检测方式可实现大范围成像区域,发现潜在的泄漏点,且可对泄漏气体的扩散方向做出准确判断,具有直观、高效、安全等特点。红外成像检测技术适用于快速检测已知泄漏气体种类的场合,但较难精确识别气体的种类。红外光谱成像检测融合了成像和光谱检测的优点,不仅能够探测到气体泄漏,而且能够识别气体类型,但高昂的价格限制了其推广使用。基于红外焦平面的气体泄漏热成像检测技术因其高探测效率、远距离检测以及动态图像直观显示等特点,已成为当前国内外迅速发展的气体泄漏检测重要手段之一[1]。然而,从探测器灵敏度考虑,早期产品大多采用成像波段范围局限于中波或长波的制冷红外焦平面探测器[6-9],单一系统难以有效覆盖常见的工业有害气体,不仅价格昂贵,限制了产品的推广使用,而且制冷红外焦平面探测器的寿命和可靠性较低,难以满足外场工业气体泄漏监测的昼夜连续工作的需要。近年来,随着非制冷红外焦平面探测器技术的发展[10],探测器灵敏度得到迅速提高,且价格不断下降,在传统军用和民用领域的应用得到迅速扩展。由于非制冷红外焦平面探测器属于热电探测器,且无需低温制冷,价格、寿命和可靠性等更适合工业危险气体泄漏热成像检测,特别是近年来从传统的长波红外拓展到中波+长波3~14 μm的宽波段响应,可望采用单一非制冷焦平面探测器实现大多数工业危险气体泄漏的成像检测与分类,应用空间广阔。

近年来,基于非制冷红外焦平面探测器的工业气体泄漏红外成像检测技术走向成熟,在提高探测器灵敏度的基础上,通过不同的成像模式及其图像增强处理技术,已实现了多种实用的检测系统。文中在分析不同工业气体泄漏红外成像检测模式的基础上,重点分析基于差分光谱滤波的工业气体泄漏云团红外成像遥测技术及其特点。

-

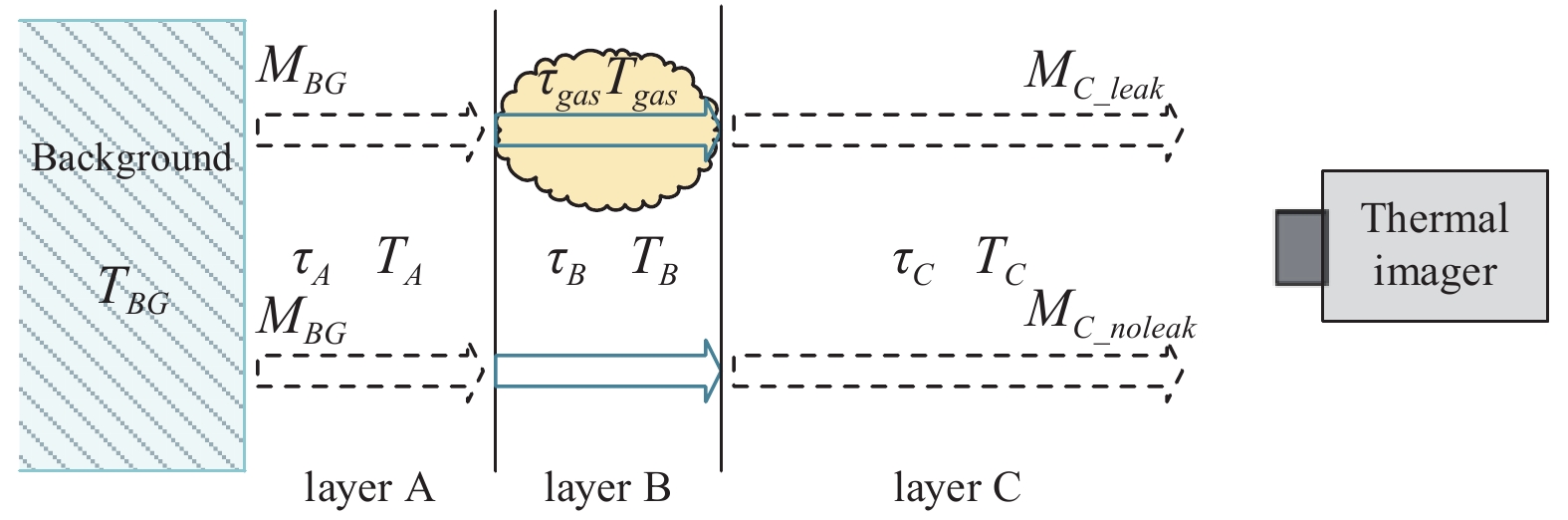

气体泄漏红外成像检测原理如图1所示[11-12]。工业危险气体在3~17 μm波段存在特征吸收线谱,当红外成像检测仪视场中存在动态泄漏气体时,在相应的吸收波段会形成动态的辐射差异,从而形成目标场景红外辐射灰度差图像信息,气体浓度越大,吸收越强,灰度差异越明显。因此,通过检测动态气体痕迹图像可实现气体泄漏的探测,根据浓度差异可判断气体的浓度。

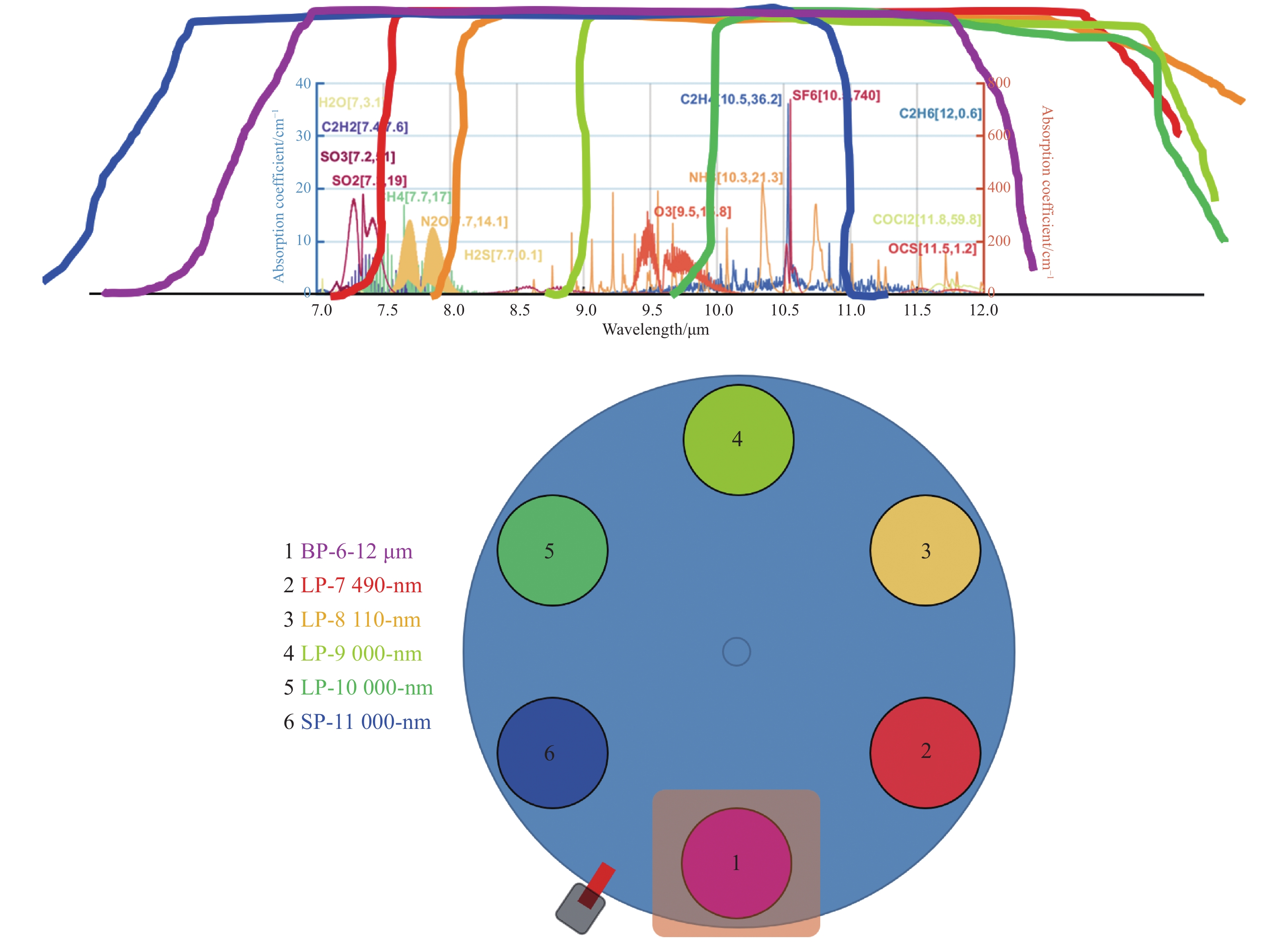

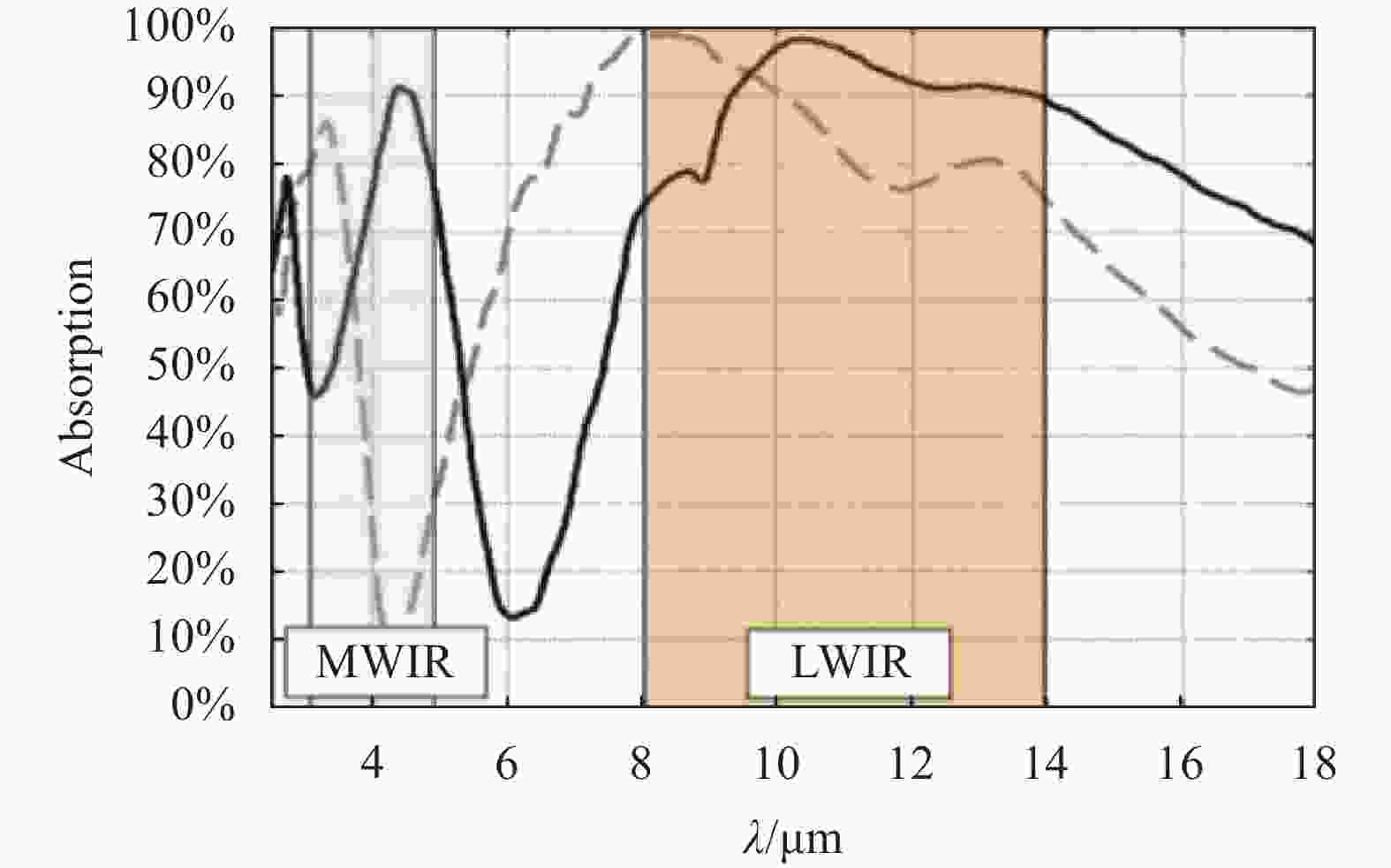

图2为典型工业气体的红外波段特征吸收线谱图[13]。红外光谱成像的分辨波段越细,气体光谱区分度越高。在探测灵敏度一定时,工作波段宽度(即光谱区分度)与成像信噪比相互制约。因此,根据探测器灵敏度设置合适的波段宽度是红外成像检测实际应用应考虑的重要因素,需要综合平衡光谱区分度与成像质量。

-

工业气体泄漏探测的非制冷IRFPA主要有多晶硅和氧化钒(VOx)的探测器。常规非制冷IRFPA响应为8~12 μm,可用于长波特征吸收峰的工业气体检测(如图2(c)所示)。由于非制冷IRFPA属于热电探测器,其响应可拓展到中波红外、长波红外乃至太赫兹波段,故宽波段非制冷IRFPA受到普遍关注。

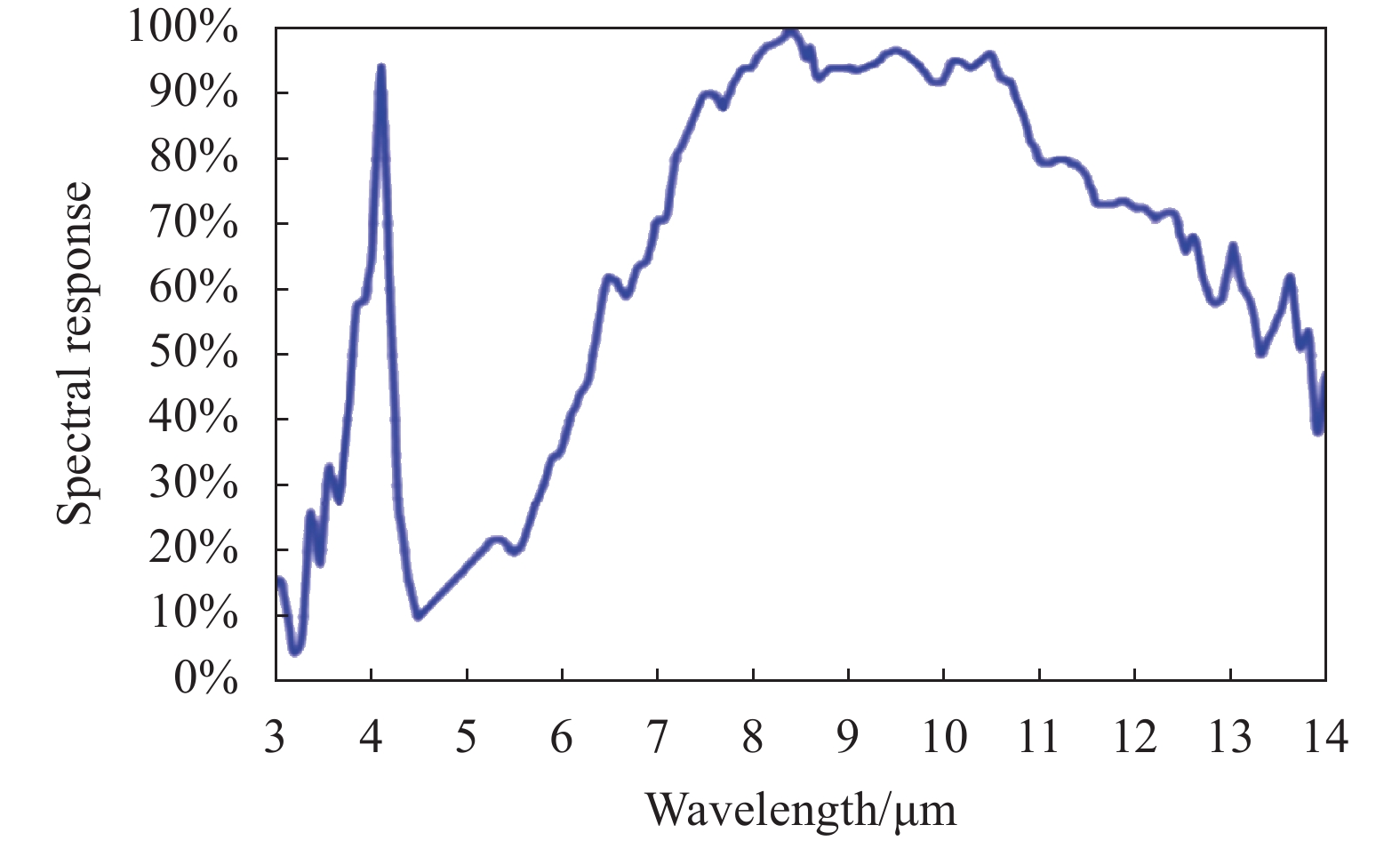

2004年,萨里大学萨里航天中心和法国ULIS公司在美国AFOSR的资助下,提出低成本小型非制冷中波红外热成像概念[14]。ULIS公司于2011年底首次推出多晶硅宽波段非制冷IRFPA Pico640 E-BB[15],探测器规模640×480,光谱响应2~16 μm (如图3所示),像元尺寸17 μm,NETD<50 mK,主要用于气体泄漏检测[16],在长波红外吸收峰7 μm附近的响应有较大提高,但在中波红外3.3 μm附近的响应较低。

2006年,美国DRS公司在美国DARPA的资助下研究MWIR/LWIR非制冷IRFPA[17],并于2009年开发出像距17 μm的640×480宽波段IRFPA[18],采用独特的双光学吸收腔“伞形”像元结构[19],使光谱响应在3~20 μm上都得到较大提高(如图4所示)。

2013年,以色列SCD公司推出宽波段非制冷VOx探测器和机芯组件[20],探测器阵列640×480,像元间距17/25 μm,NETD<35 mK,帧频25/30/60 Hz。虽然其资料上强调用于气体检测成像,在10~14 μm波段响应高于90%,在3~5 μm波段平均响应得到较大提升[21-22](如图5中黑色实线所示),但在烷类气体探测波段的光谱响应反而比一般VOx探测器响应低(如图5中灰色虚线所示)。

2017年,加拿大国家光学研究所INO采用石墨烯薄膜增强了在3~14 μm的吸收,改善了以往宽波段IRFPA在响应区间的振荡特性[23],NETD从60 mK降到22 mK;2018年,研制了17 μm像距的宽波段光谱响应探测器(如图6所示),具有平坦的高响应率[24]。

2011年,北京理工大学金伟其提出基于宽波段非制冷IRFPA的工业气体泄漏成像检测理论和技术思想[25],获得北京市自然科学基金重点项目支持,牵引烟台艾睿公司(640×512, 17 μm, NETD≤ 30 mK,光谱响应如图7所示)和北方广微公司(384×288, 25 μm, NETD≤40 mK,光谱响应如图8所示)分别研制了VOx宽波段非制冷IRFPA及其组件[26],实现了对常见工业危险气体(如烷烃、烯烃、氨气、六氟化硫)泄漏的成像探测。

综上所述,ULIS和SCD拓展和提高了非制冷IRFPA的性能,但在烷类气体探测所需波段响应仍有上升空间。DRS和INO的宽波段探测器光谱响应较高,但国内很少见到产品。目前国内研制的宽波段非制冷IRFPA已达到常见工业危险气体泄漏检测的应用要求。

-

近年来,国内外针对工业气体泄漏检测提出了多种红外成像检测模式。

-

目前气体泄漏红外成像检测仪器大都采用宽波段非制冷IRFPA+单/多个窄带滤光片的组合方式,实现某类或多种工业气体泄漏成像检测。

2012年,金伟其等研制了基于3~14 μm宽波段IRFPA的气体泄漏红外成像检测原理样机(如图9所示)[27-28],通过转轮选择窄波段滤光片,实现了对多种常见工业危险气体(如乙烯、氨气、六氟化硫)泄漏的成像探测。

2017年,在北京市科学仪器培育项目的支持下,金伟其等进一步针对石油天然气泄漏检测进行深入的研究,研制了宽波段非制冷IRFPA+单特征滤光片的红外成像检测样机[12],并与北京智慧共享技术服务公司合作实现技术产品转化(如图10所示),在多家研究院和企业完成了典型工业气体泄漏红外成像检测的应用示范,取得了接近FLIR制冷检测热像仪GF320的成像效果(如图11所示)。

2016年,英国格拉斯哥大学Miguel A. Preciado等设计了一种多孔径多光谱红外成像系统(如图12所示)[29],由2×3阵列的非制冷长波红外热像仪组成。将7~14 μm波段分成六个光谱通道,六个热像仪分别安装不同中心透射波长和带宽的滤光片,每个滤光片通带宽度为798 nm[30]。该系统以陶瓷红外灯作为辐射光源,对甲烷、丙烷和丁烷气体进行了探测和识别实验。由于采用非制冷红外热像仪和窄带宽的滤光片,系统灵敏度相对较低,在背景辐射较高时,成像效果良好,但未给出自然环境下气体的检测性能。

2018年,罗兹理工大学P. Więcek等使用SCD宽波段非制冷IRFPA设计了气体泄漏红外成像检测仪VOxgas640 (如图13所示)[31-32],采用装有两个带通滤光片的转轮以区分不同的气体,输出帧频15 Hz。使用基于高斯混合的背景分割模型以及结构相似性指标和Bhattacharyya距离的直方图增强算法,实现了对NH3、C3H8、C4H10和CH4气体的泄漏成像检测。

2019年,FLIR推出了甲烷泄漏非制冷红外成像检测仪FLIR GF77(如图14所示)[33],响应波段7.0~8.5 μm,阵列规模320×240,像元距25 μm,NETD<25 mK,噪声等效浓度路径长度(Noise Equivalent Concentration Path-Length, NECL)小于100 ppm·m,开发了单触式电平/跨度自动调整功能增强对比度等目标增强方法,采用高灵敏度模式突出显示烟缕运动。

-

1991年,在法国国防部军械装备局DGA资助下,法国Bertin公司提出基于差分式光谱滤波的气体泄漏红外成像检测技术[34-36]。2007年,推出Second Sight系列气体成像仪,使用多种长通宽带红外滤光片,分为参考滤光片和活动滤光片(如图15所示)[37]。通过参考滤光片的红外辐射不受有无气体的影响,通过活动滤光片的红外辐射包含目标气体的吸收波段,采集相邻两种滤光片的红外图像进行差分运算提取气体云团目标,能区分光谱特征相近的不同气体(如甲烷和丁烷)。烷类气体探测成像系统采用非制冷α-Si探测器,响应波段7~14 μm,阵列规模382×272,NETD≈40 mK。

差分式光谱滤波的气体泄漏红外成像检测模式特色可有效减小滤光片自身辐射与反射的影响,灵敏度较高,但帧频较低。

-

2005年,加拿大Telops公司针对气体成分检测需求,研究基于傅里叶变换的气体红外高光谱成像仪[38-39],其商用成像光谱仪FIRST采用制冷型MCT探测器,阵列规模320×256,工作波段为8~12 μm,光谱分辨率为0.25 cm−1,能够获得目标气体的光谱域和空间域信息。之后,基于FIRST又开发了MWIR和LWIR波段气体泄漏检测高光谱成像仪Hyper-Cam(如图16所示)系列[40-43],响应波段涵盖1.5~5.4 μm和7.4~12 μm[44],能对常见危险气体泄漏进行检测。

2011年,日本Takahide Sakagami等[45]采用非制冷IRFPA设计了气体泄漏探测识别系统(如图17所示),响应波段7.5~13.5 μm,NETD为33 mK,能探测气体泄漏并识别气体类型。对氢氟烃气体(HF-152 a)进行了测试,光谱测量结果与标准数据库一致。

红外成像光谱仪是目前最先进的成像模式,能同时获得光谱分辨率和空间分辨率较高的图像,实现气体泄漏探测及泄漏气体识别。但由于探测器灵敏度限制等原因,仅有很少采用非制冷IRFPA的研究报道,从而造成这类设备价格、寿命和可靠性问题。

-

2012年,美国Rebellion Photonics公司研制了基于非制冷IRFPA的气体泄漏云团红外成像检测仪GCI [46-47](图18所示),采用法国Sofradir公司的非制冷IRFPA,阵列大小1024×768,像元17 μm,帧频30 fps,光谱响应范围7~12 μm,能够对多种烷类气体进行成像[48]。2013年,测试了对丙烷气体的成像效果[47](如图19所示),当环境温度和丙烷气体温度相差7 ℃时,以天空为背景,可以有效地观察到气体泄漏。

GCI采用的成像映射光谱技术(Image Mapping Spectroscopy,IMS)基本原理如图20[49-50]所示,分光装置由物镜、映射镜、棱镜和微透镜阵列组成。物镜将来自场景的辐射聚集到映射镜上,映射镜由一系列镜面构成,每个镜面都有自己的三维倾斜角度,在由小镜面倾斜角决定的方向上,每个镜面反射一列图像,所有的镜面最终形成了如图20所示的子图像;准直镜收集子图像,棱镜阵列将子图像每一列的光谱信息分散开来并填充在光学空隙中,微透镜阵列将来自棱镜的子图像聚焦在探测器上;最后,利用算法重构原始目标信息。由于采用降低空间视场而获取光谱信息的方法,其最终的有效图像大小只有225×115 pixel,视场11°×6°。GCI具有较好的烷类气体成像效果,在中国市场已有成功的应用,但分光装置复杂,成本较高。

综合分析多种非制冷IRFPA的工业气体泄漏红外成像检测模式,宽波段探测器+窄带滤光片的成像模式存在图像信噪比低、识别气体种类有限的不足,红外光谱成像模式存在受到非制冷IRFPA灵敏度限制、结构复杂、价格高等不足。考虑到目前非制冷IRFPA成像性能得到提高,并借鉴各成像模式优势,笔者选择差分式长通光谱滤波式成像模式,具有成像信噪比高、光谱范围宽、多光谱组合、可靠性高、性价比高等优点。

-

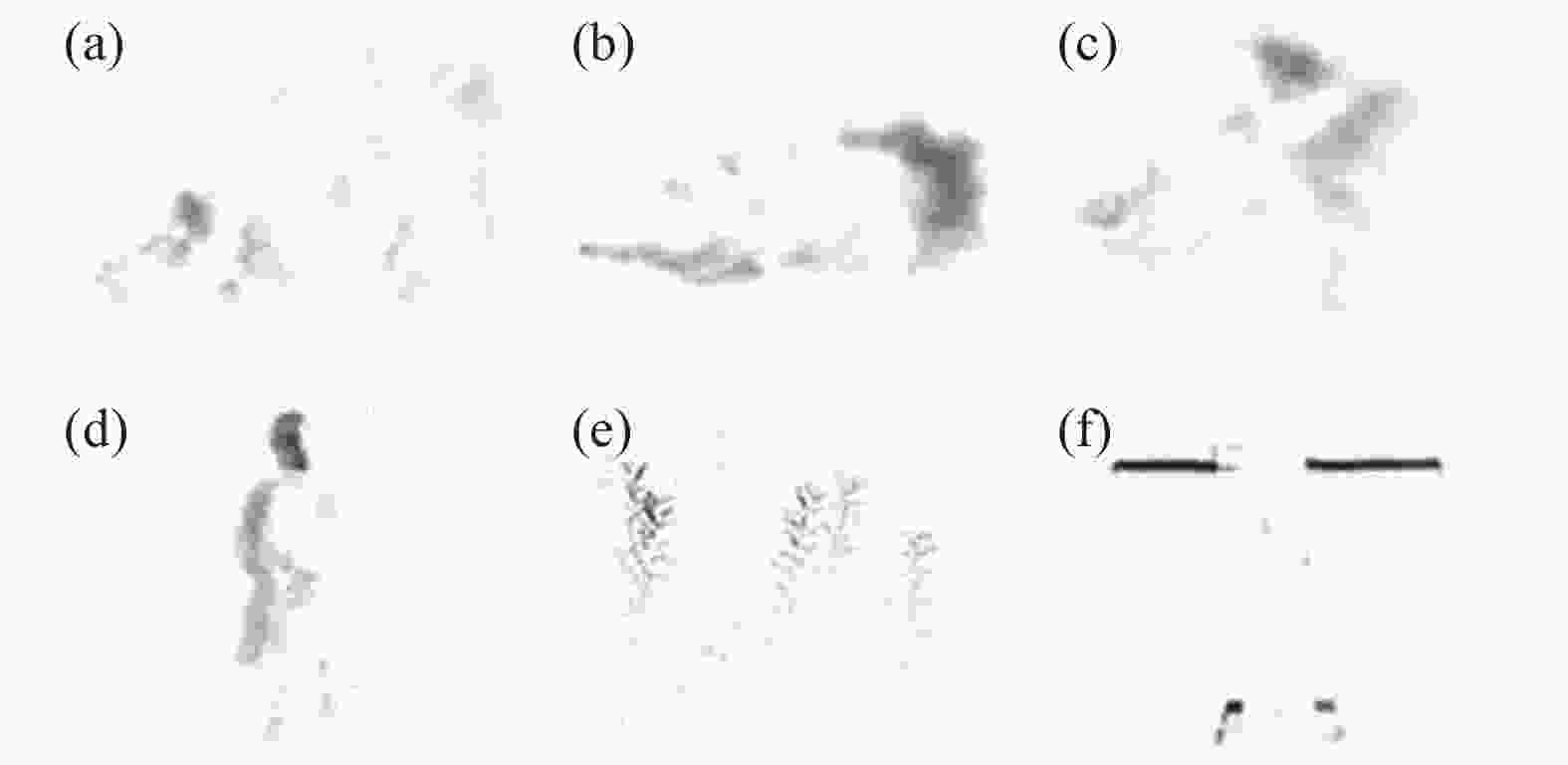

笔者设计了一款差分式光谱滤波气体泄漏红外成像检测系统(如图21所示)。系统采用烟台艾睿宽波段非制冷IRFPA (LA6110-PL16113 S00)和低照度彩色或黑白CMOS成像组件(Crevis MV-BX30,像元规模1024×768,像元尺寸4.65 μm,8 bit Camera Link输出)。在红外物镜(如图22所示,焦距40 mm,F数1.0)后截距中安装六孔转轮(如图23所示,BP、LP和SP分别表示带通、高通和低通滤光片),实现最高100 r/min的光谱调制。红外和可见光视频图像通过FPGA图像处理板(如图24所示)进行预处理和融合,同时控制滤光转轮旋转及定位、视频图像采集、数字视频图像传输、人机交互等。

研制的样机系统如图25所示,六个滤光片的组合可检测的典型工业气体种类如表1所示。图26给出了采用长通滤光片获得的气体泄漏热图像及渲染效果。可以看出:采用长通滤光片获得的图像信噪比较高,气体云团的检测效率也更佳。

Filter combination Spectral band Gas type 1-2 6-7.49 Ethylene, Butane, Toluene, Carbon disulfide 2-3 7.49-8.11 Methane, Nitrous Oxide, Ethylene oxide,

Ethyl mercaptan3-4 8.11-9 Difluoroethane, phenol,

2-propionic acid4-5 9-10 Ozone, Ammonia, Cyclopropane 6-1+5 10-11 Sulfur hexafluoride, Ethylene, Acrylonitrile 1-5 11-12.5 Ethylene oxide, Phosgene, Carbon oxysulfide VIS+IR Water vapor, heat convection Table 1. Gas type detectable by 6 filter combination

-

图像差分是光谱滤波式红外成像模式最大的特点之一,其采用两个截止波长不同的高通滤光片分别进行成像,并由两者的差异解算出两个截止波长差之间辐射差异图像,相对于直接采用窄波段滤波成像,能够获得更多的入射辐射量。因此,成像信噪比较高,且后续处理属于典型的计算成像范畴,利用现代数字图像处理技术可望获得更好的成像检测效果、更弱的泄漏气体痕迹或更远的气体泄漏检测距离。

除常规的红外焦平面成像的图像处理方法外,需特别关注以下几个环节:

(1) 单通道成像的非均匀性校正

各成像通道的通光波段变化将带来非均匀性校正系数矩阵的变化,因此,需要进行六个通道的辐射定标。考虑到检测环境及气体目标温度范围,采用常温黑体进行二点定标模型,以确定每一个通道的非均匀性校正系数增益矩阵

$ {a_i}(i,j) $ 和偏置矩阵$ {b_i}(i,j) $ ,并在实际使用过程中采用挡板或基于场景的自适应非均匀性校正方法完成校正系数矩阵的修正。该类方法已有较多的研究,这里主要进行算法的引用。(2) 不同波段图像之间的均衡化处理

由于系统采用不同高通滤波成像之差构成气体泄漏检测图像,各通道虽然已进行了各自的非均匀性校正,但各通道的响应(即增益与偏置)并不一致,因此,需要对各通道图像进行均衡化处理。

若通道1和2的两点校正模型分别为:

式中:

$ {x_1}(i,j) $ 和$ {x_{\text{2}}}(i,j) $ 、$ {y_1}(i,j) $ 和$ {y_2}(i,j) $ 分别为通道1和通道2探测器输出的原始数据以及经两点校正的数据;$ {a_1}(i,j) $ 和$ {a_2}(i,j) $ 、$ {b_1}(i,j) $ 和$ {b_2}(i,j) $ 分别为通道1和通道2的增益和偏置矩阵。为使通道2的响应与通道1一致,需再进行通道间的线性变换—二次均衡校正:以通道1为参考基准,使通道2校正模型与通道1一致。设对通道2进行二次均衡后的输出数据为

$ {y_3}(i,j) $ ,对应的增益和偏振矩阵分别为$ {a_3}(i,j) $ 和$ {b_3}(i,j) $ 。若使其输出数据与通道1校正后的响应一致,则有:将公式(1)与公式(2)对比,可得到:

故经二次均衡校正后,两个通道输出相减构成的带通滤波输出为:

(3) 泄漏气体痕迹提取方法

由于实际石油天然气设施环景中往往存在人员走动、随风飘动的树木花草和运动车辆等复杂运动背景,对泄漏气体的判断会造成明显干扰。为此,采用帧间差分图像(带通滤波模式)或差分光谱图像(差分光谱滤波模式),利用支持向量机(Support Vector Machine,SVM)和深度学习等智能处理方法有效提取气体痕迹(如图27所示),准确率可达92.5%[51]。

Figure 27. Samples collected. (a)~(c) Leaking gas; (d)~(f) Interference from people, trees, pumping units, etc.

(4) 可见光+红外通道融合图像处理

工业气体泄漏红外成像检测系统通常包含红外和可见光通道,除可提供人们熟悉的可见光监视场景外,同时提供不可探测的泄漏气体动态痕迹红外图像和融合图像,以及采用伪彩色渲染气体痕迹表示不同浓度范围。另外,可见光与红外图像融合还可提高对气体痕迹与水蒸气等的检测能力(如图28所示)。

(5) 泄漏气体识别与浓度的预测方法

不同的光谱滤光片可用于不同泄漏气体的探测和识别,并根据泄漏气体痕迹的标定实现从痕迹图像灰度到气体浓度的估计。

目前已进行了甲烷、二氟乙烷、六氟化硫、汽油(如图29所示)、乙烯等气体的有效探测,并可通过假彩色渲染气体的浓度,但具体的浓度水平估计依赖于实际标定方法与过程。

-

工业气体泄漏红外成像检测技术已展现出广阔的应用前景,成为近年来技术发展的关注点,对于达到“碳达峰”和“碳中和”战略目标以及预防工业气体泄漏事故具有重要的实际意义。文中在分析当前基于非制冷IRFPA的工业气体泄漏红外成像检测模式的基础上,重点研究了差分光谱滤波红外成像检测方法的特点及其图像处理重点,对于工业危险气体泄漏检测技术和装置的发展具有促进作用。

研制了差分光谱滤波红外成像检测实验系统,但系统图像处理方法仍需进一步深入研究,相关处理算法及其效果将在后续的研究和论文中详述。

Research on infrared imaging detection and differential spectrum filtering detection methods for industrial gas leakage

doi: 10.3788/IRLA20210714

- Received Date: 2021-09-28

- Rev Recd Date: 2021-12-01

- Available Online: 2022-08-31

- Publish Date: 2022-08-31

-

Key words:

- industrial gas leakage /

- infrared spectral imaging /

- uncooled IRFPA /

- differential spectral filtering /

- image processing

Abstract: Industrial gases, represented by oil and natural gas, have penetrated people's lives and production processes. Gas leakage has become one of the major disasters in current industrial production, transportation and other fields. Meanwhile, methane emissions have become the main target of China’s "carbon emissions" strategic goal. Rapid and effective gas leakage detection technology and instruments have become the focus of research at home and abroad. In response to the improvement of the performance of the uncooled infrared focal plane array (IRFPA) in recent years, its low cost, long life and high reliability can adapt to industrial gas leakage of infrared imaging detection requirements of continuous work day and night, and a variety of gas leakage infrared imaging detection modes have been developed. Based on the analysis of different infrared imaging detection modes of industrial gas leakage, this paper designs and develops an infrared imaging detection experimental system of industrial gas leakage based on differential spectral filtering, analyses and puts forward five video image processing methods that need to be studied, and gives relevant processing models or typical processing examples. The results show that the imaging detection mode has the characteristics of high sensitivity and is an effective infrared imaging detection technology for gas leakage.

DownLoad:

DownLoad: