-

近年来,随着人们的生活水平不断提高以及工业技术的不断发展,CO2的排放量逐年增多,大气中的CO2含量也逐渐增加,各种生态问题会随之出现,环境问题已经成为人类所面临的重大问题[1-2]。大气中的CO2平均值已经上升到400 ppm (1 ppm=10−6)以上,增多的CO2导致全球气候变暖、极端天气频现等一系列问题,如2019年意大利威尼斯遭受60年以来最大洪水侵袭[3]。同时,CO2具有无色无味无毒特性,当其浓度达到一定量时,会导致人头痛甚至死亡。因此,CO2浓度检测成为了当今人们生活生产的安全保障要求之一,具有良好的应用前景。2017年,Hodgkinson J设计了一款圆柱形CO2传感器,直径20 mm,高16.5 mm,实现了最低1 ppm的检测[4]。2019年德黑兰大学采用聚类(甲基丙烯酸甲酯) PMMA基通道和PDMS聚合物研制出超低功耗的CO2传感器[5]。国内相比国外虽起步较晚,但各大高校与研究所积极支持和发展各类传感器,现已实现较大进步。2015年,中北大学设计了一款三气体传感器,实现了对CH4、CO2、CO的检测[6]。

文中对非分光法检测CO2浓度进行了研究,设计了一款体积小、便携的CO2检测系统。系统利用STM32单片机作为控制核心,通过信号处理电路将传感器信号经过处理之后,利用ADC采集输出信号的峰峰值,并根据浓度拟合公式和温度补偿公式转换为气体浓度数据。测试结果表明,该系统的测量范围为0~50000 ppm,最大相对误差值为1500 ppm,能够满足防火报警、矿下监测等场合的安全需求。

-

许多气体分子都具有吸收光谱中某一特定频率的红外辐射的特性。其原理为当红外辐射入射在气体分子上时,当红外线的波长与分子的自然频率或共振相匹配时,会引起分子振动能级间跃迁[7]。非分光红外检测气体是根据所检测气体的原子振动频率及其跃迁能量的唯一性,即当一束具有连续波长的红外光透过待测气体时,气体会吸收相应波段的红外光,从而衰减了此波段的红外光能量,根据进出气室的红外光强不同进一步推出环境中气体分子的浓度。该吸收关系符合朗伯-比尔定律[1, 8-9],如公式(1)所示:

式中:

$ C $ 为气室内待测气体浓度;$ \varepsilon $ 为气体的吸收系数,根据波长不同而改变;$ L $ 为红外光透过待测介质的距离;$ I_0 $ 和$ I $ 分别为吸收目标气体前和后的红外光强。然而该定律只针对于单色光成立。从理论上来讲,所测CO2的浓度与红外光的衰减程度遵循朗伯比尔定律,但在实际的测试中,如果直接使用该定律进行计算,由于环境温湿度对其吸收系数影响较大,所得出的CO2浓度将不准确[10]。因此,文中采取用标准CO2气体标定的方法,建立气体浓度值与电压峰峰值的关系,通过函数拟合得到气体浓度与电压值的函数。鉴于任何函数都可以通过泰勒展开为高阶多项式,在数据处理时,应该优先选择多项式拟合。 -

光学气室是其中很重要的一环,设计合适的光学气室对检测系统的性能具有非常大的影响。从理论上讲,光学气室的光程越长,待测气体对辐射的吸收就越充分,但在实际应用中,如果气室的光程过长,就会导致红外辐射的损耗变多,这将会导致测量结果精度的降低,因此气室的光程不应过长[11-12]。所提设计利用SolidWorks建立气室的三维模型,然后将整个模型导入TracePro中,对气室进行仿真。

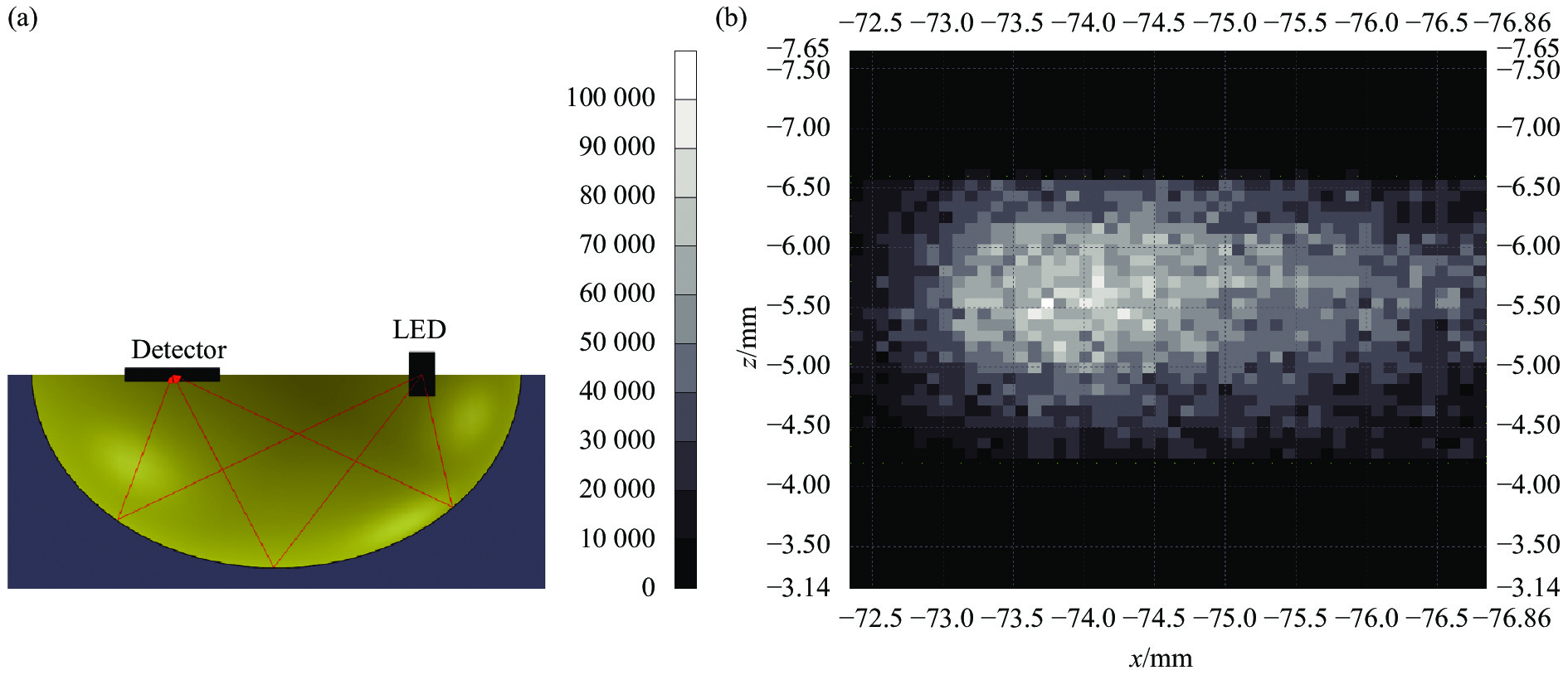

文中设计使用的气室结构为椭球形,椭球形具有和椭圆相似的光学特性,即由一个焦点射出的光线经过椭球壁反射后必定经过另一个焦点。所建立的气室及光线效果,如图1所示,气室具有体积小、光程适中的特点,通过对其内壁进行镀金处理,在一定程度上减小了光线传播过程中的损耗,总体直径为22 mm,椭球气室长半轴为10 mm,光程为16 mm。在仿真中,设置波长为4.26 μm,气室内表面反射率设置为95%,以及探测器38.9°内可吸收光。之后设置光源辐射总功率为1 W,光线设置为10000条,且每条光线能量均分。采用此结构能够实现光线充分利用,合理增加光程,实现检测范围和精度提高。

-

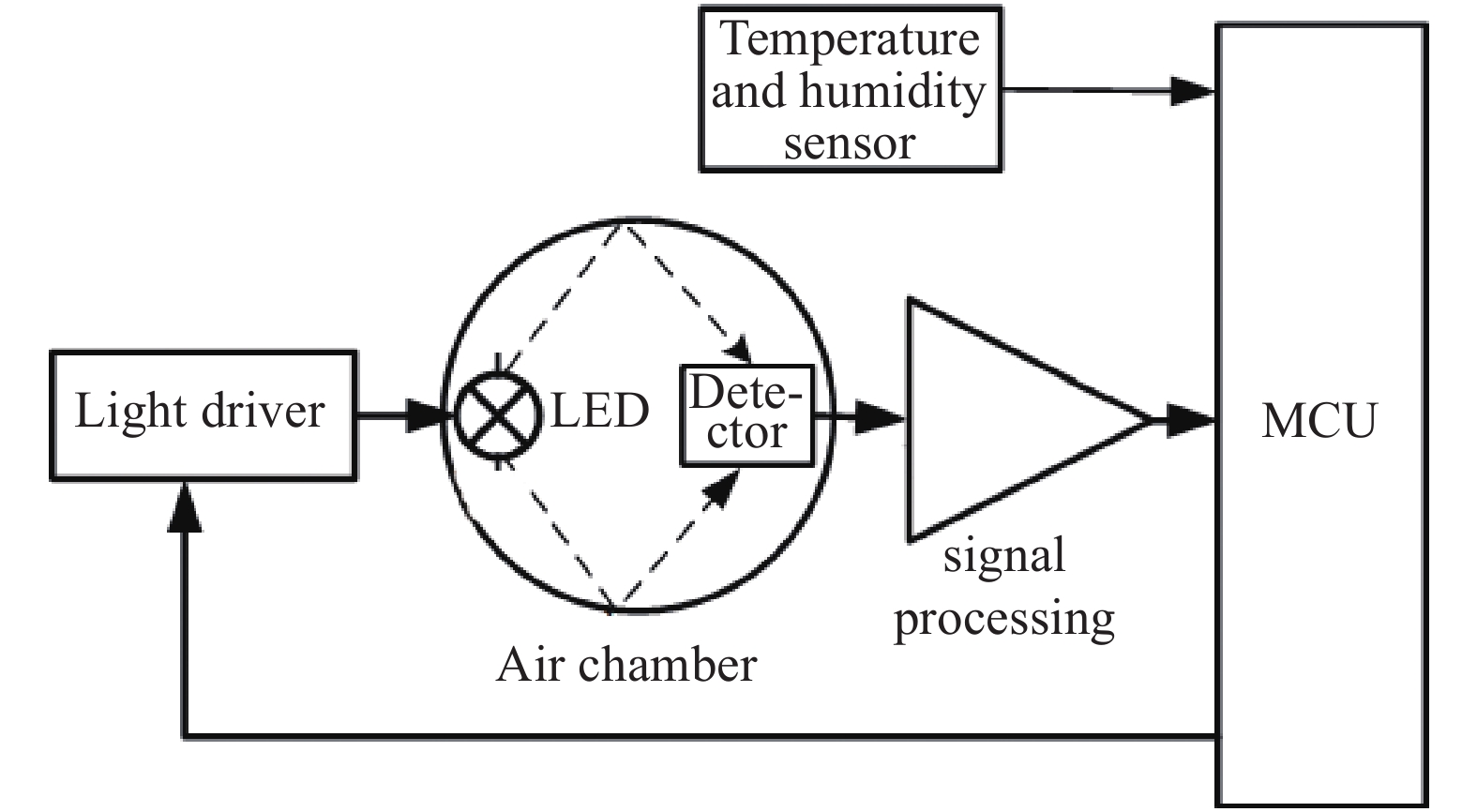

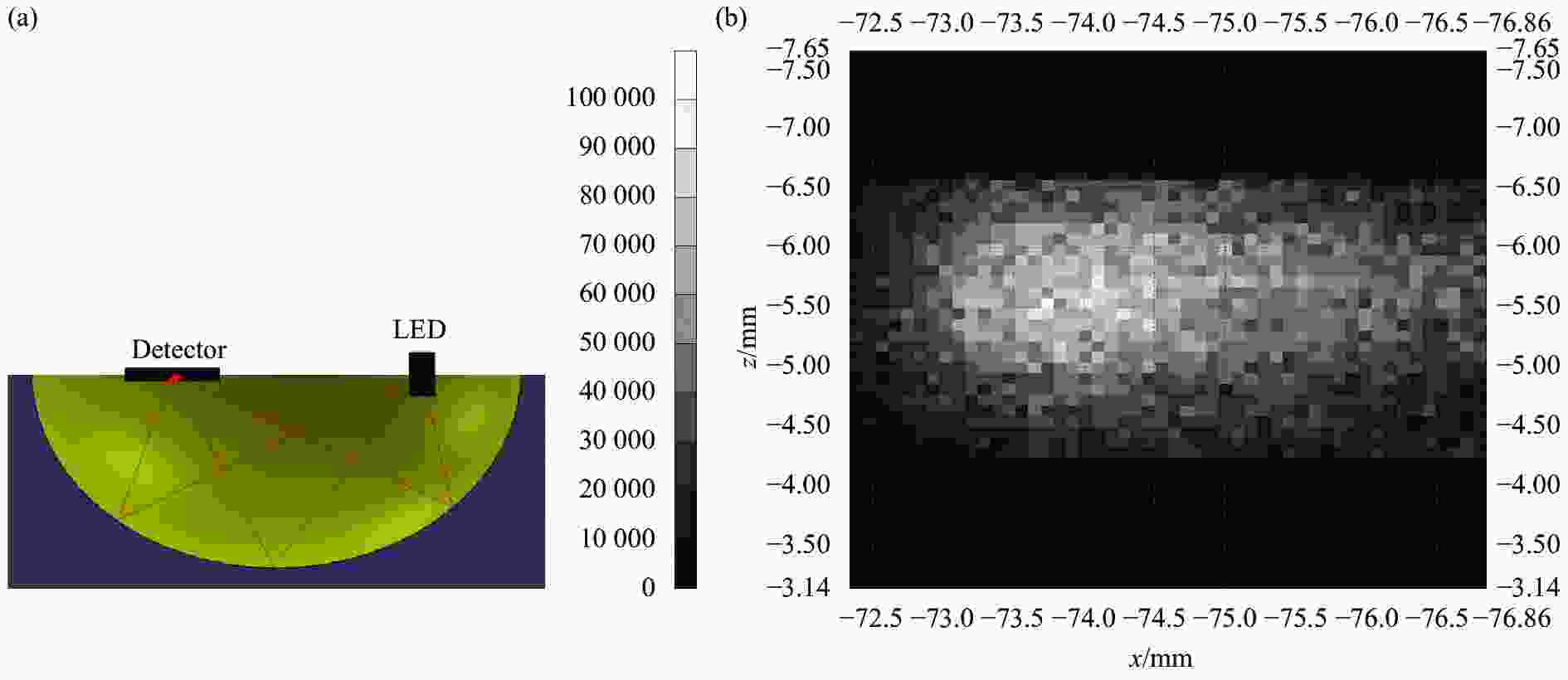

一个良好的系统不只是能够在满足基本设计需求,还应具有良好的可用性和稳定性、可扩展性以及模块间的低耦合性。红外CO2传感器系统设计框图如图2所示。该设计采用模块化设计方式。各个模块之间的工作流程为:首先单片机发出方波驱动信号输入给光源驱动模块,光源发出红外辐射;红外CO2传感器捕捉到含有气体浓度信息的红外辐射后,产生感应电流,通过前端放大器的放大之后,由信号调理模块放大滤波处理;同时采集温湿度信息,用于单片机处理信号与计算浓度值时进行温湿度补偿;单片机内部ADC对信号调理模块处理后的信号进行采样、分析与处理,最终得出气体浓度信息。

-

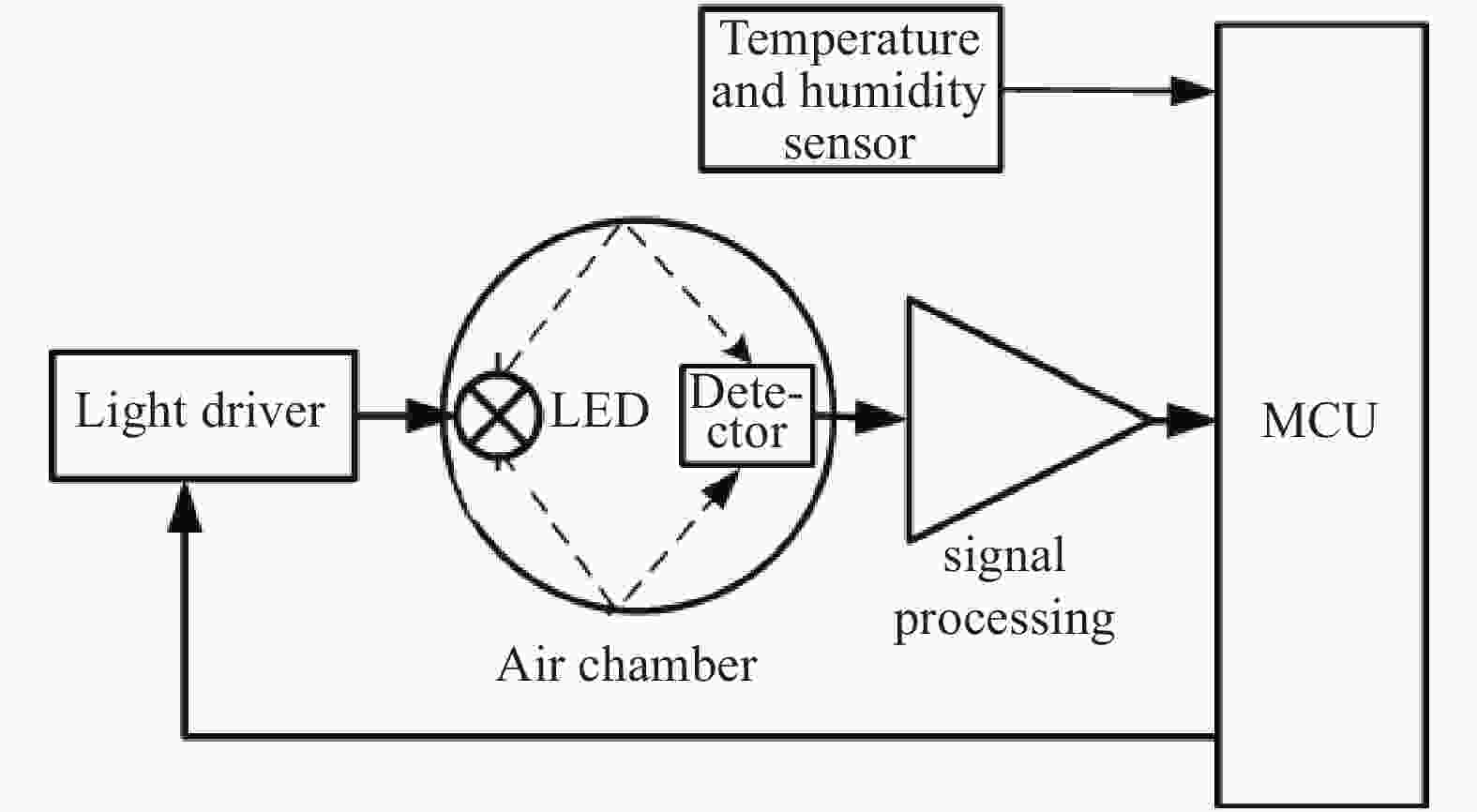

文中系统的电源设计采用兼容5 V与3.3 V的双电压输入方式,电源输出为稳定的3.0 V。电源芯片是TC1185,低压差,低功耗运行,小型化,输出电压精度高,输出电流可达到150 mA,可以为整个系统供电。电源部分设计电路如图3所示。

-

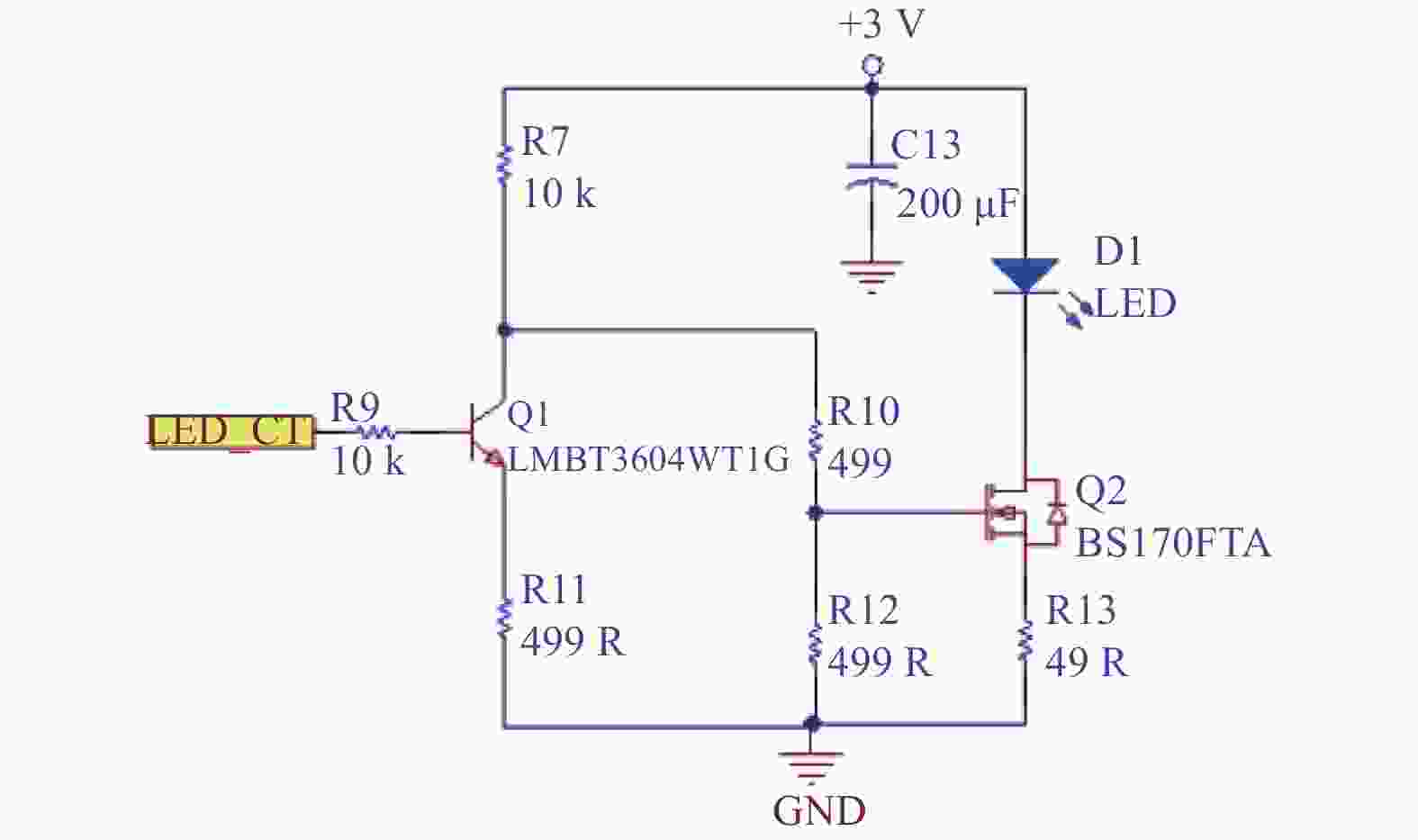

光源驱动电路上承STM32,下启光源,作为系统的主要驱动电路。如图4所示,将STM32发出的2 Hz的方波调制信号,经过三极管与晶体管后,控制光源的亮灭,实现光源调制。当LED_CTRL为高电平的时,三极管和晶体管导通,光源发光;当LED_CTRL为低电平的时,三极管和晶体管断开,光源关闭。由于光源开启与关闭时对系统电源影响较大,从而影响系统其他部件的正常工作,采用较大容值的钽电容降低该影响。

-

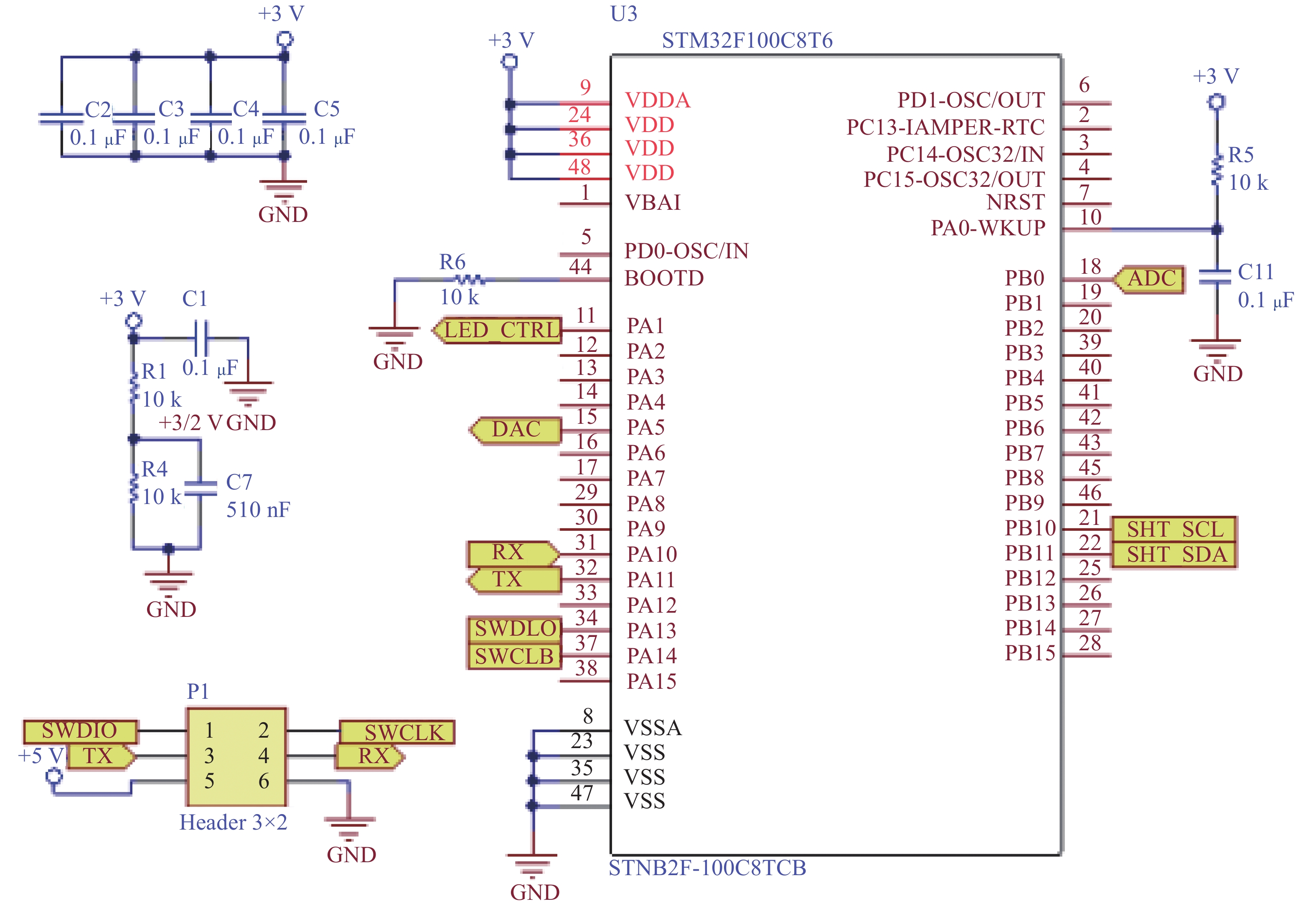

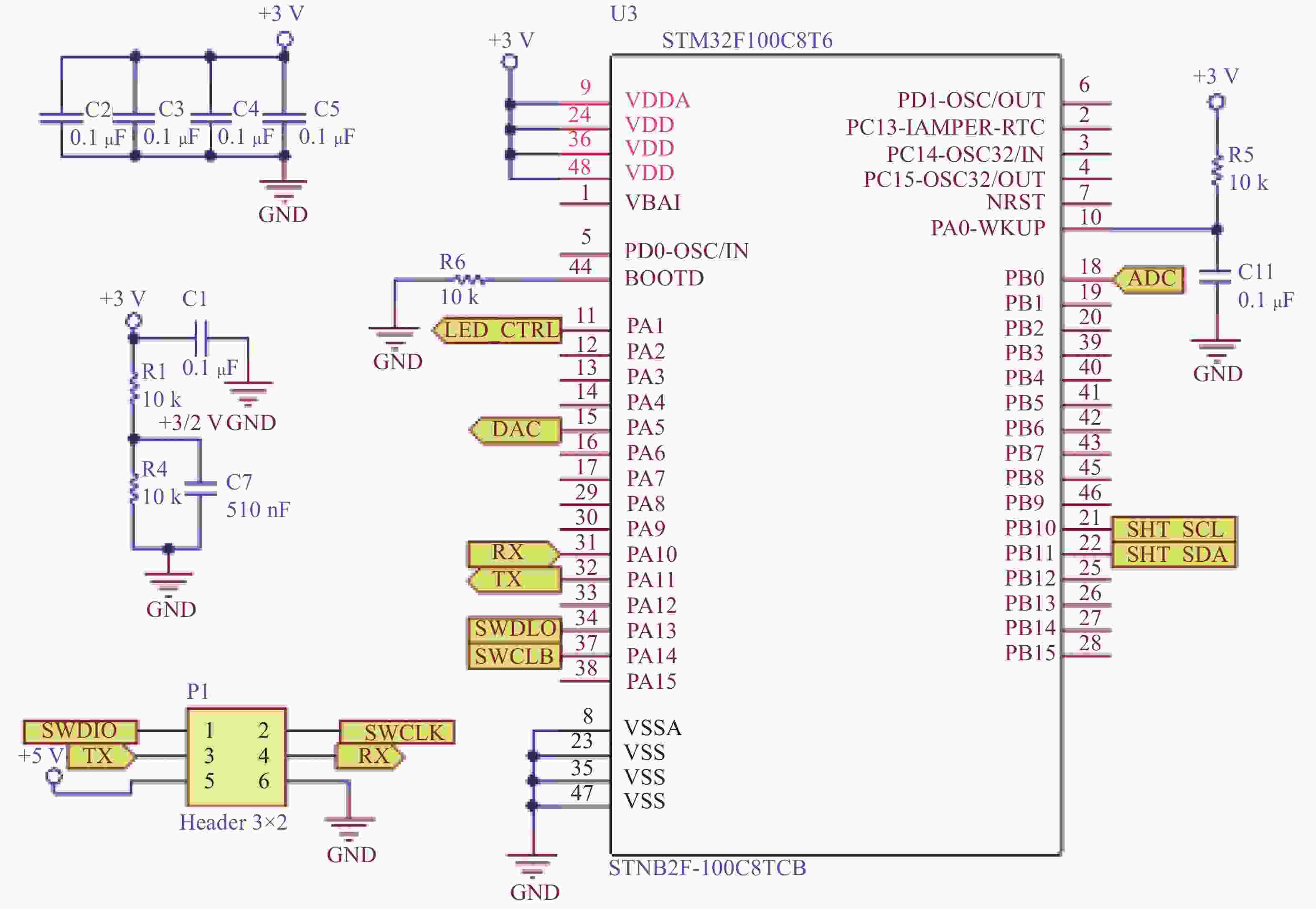

控制模块是系统进行控制输出、处理输入、信号处理与数据计算的核心部件。核心控制芯片采用STM32 F100 C8 T6 B,此型号为ST公司设计的一款低功耗的单片机,具有丰富的片上外设且设置系统工作频率为8 MHz,采用二线制下载程序。同时,芯片内部时钟相对较稳定,可以不需要外部时钟电路,简化了外围电路,有利于系统的集成化和小型化。

控制模块电路如图5所示,应在每一个单片机的电源引脚上均放置一个0.1 μF的高频去耦电容,此电容可有效防止高频噪声对MCU的影响,同时,也可以有效滤除电源引脚对外围电路的影响。控制模块电路主要作用是采集与处理ADC采集的信号,与温湿度传感器通讯,并驱动光源。

-

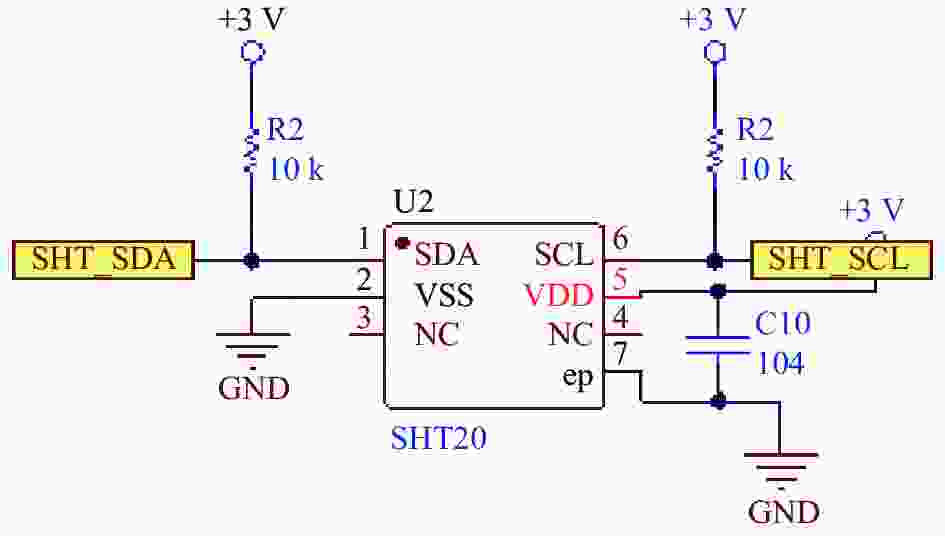

环境中的温湿度对气体传感器的影响非常大,所以利用温湿度传感器设计温度采集电路(图6)采集环境温湿度信息。采集温度信息旨在单片机计算和处理浓度信号时,对气体浓度进行补偿,以减少误差。采集湿度信息目的在于限制系统工作环境,湿度在高于设定环境时,系统自动停止运行。设计选用高精度、高稳定性和低功耗的SHT20温湿度传感器,其能够通过IIC协议输出数字信号的温度与湿度信息。

-

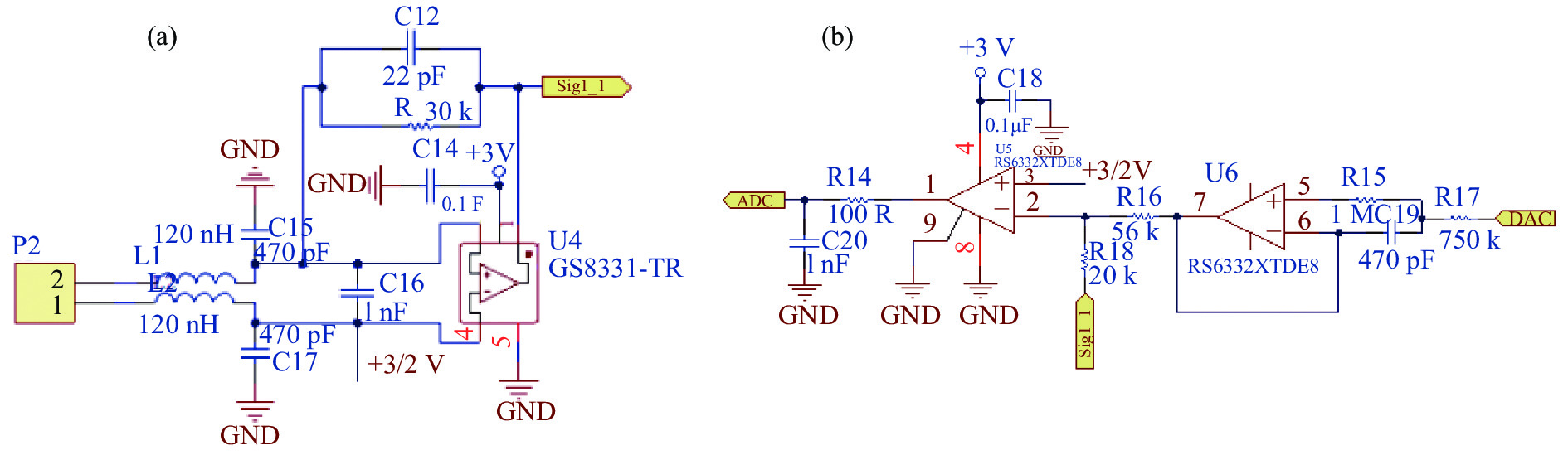

红外探测器输出信号是十分微弱的电流信号,仅为皮安级别。探测器信号处理电路如图7所示,使用放大器芯片分别为GS8331与RS6332。前级放大电路采用的是差分放大电路,将探测器输出的信号与一定的基准电压进行差分,差分放大电路的优点在于抗干扰能力强,如果环境周围有噪声干扰时,可以几乎同时被耦合到差分的两个通道上,同时能够有效地抑制电磁干扰。同时通过该电路实现低通滤波器滤除高频信号。所设计信号放大电路采用单电源供电,所以需要给原始信号一个合理的偏置电压调节信号范围,使输出信号能够完整复现波形。

-

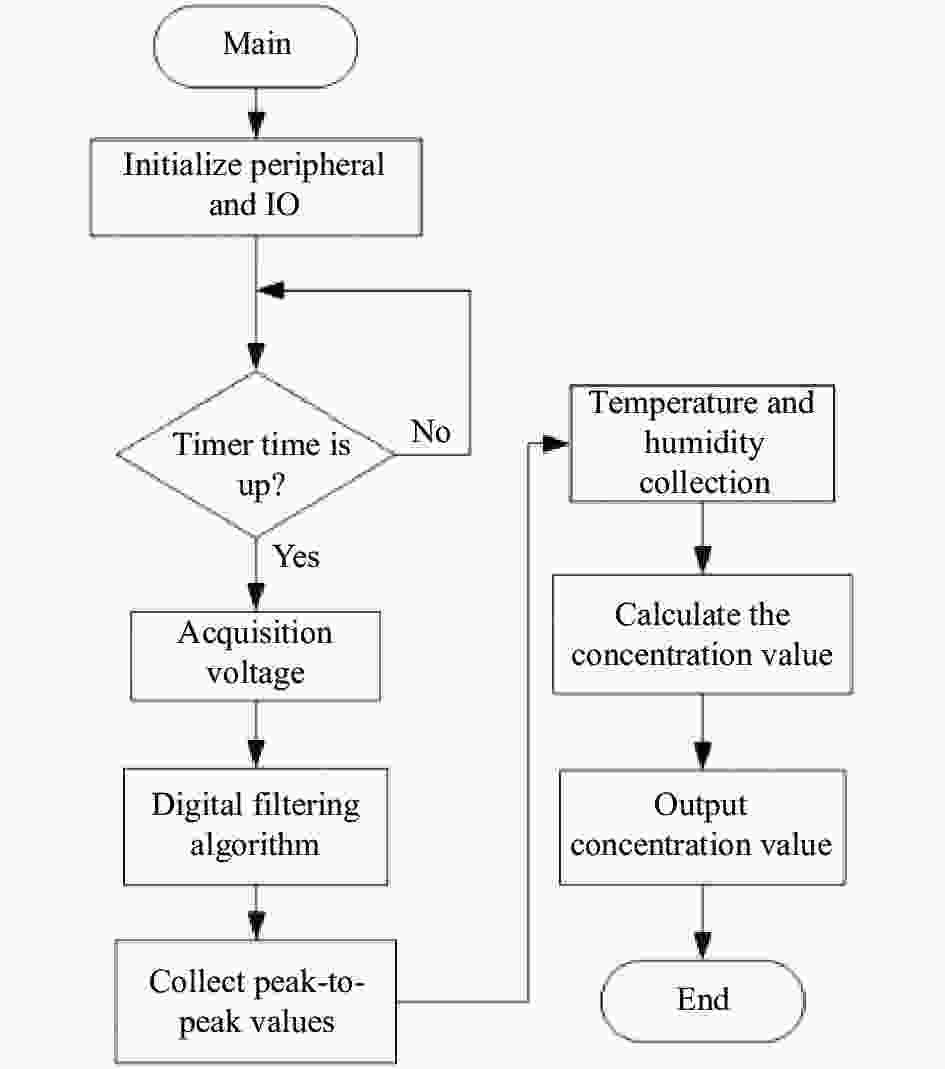

高精度应变测量系统不仅仅需要具有高精度、性能稳定的硬件系统,还需要相对应的软件系统。整个测量系统的软件部分如图8所示,包含对系统的初始化设置、对采集数据的采集、拟合计算以及对串口通信的配置,为了提高整个系统的精度,还需要采取一定的数字处理,系统采用的是数字滤波,提取滤波后的波形峰峰值,可以有效地提高信噪比。为了平衡传感器的精度与响应时间,此处的数字滤波器是特定应用[6, 11],该设计采用平均值滤波与扩展卡尔曼滤波。

-

搭建红外CO2传感器测试平台对所设计传感器系统进行测试,经过对多种情况下的多组测量数据的分析得出红外CO2传感器的精度与误差,并优化拟合系数,从而提高传感器系统的测量精度[13-15]。

搭建测试平台,将传感器放置到密闭气室内,标定实验在标准大气压和25 ℃环境下进行。为了达到测试的准确性,第一,保证密闭气室的密闭性良好;第二,确保测试环境稳定,浓度标定实验的环境稳定性是整组实验数据拟合的根本所在;第三,当气体浓度达到设定值时,等待1 min后再测量通道的峰峰值,并记录它们对应的浓度值。

-

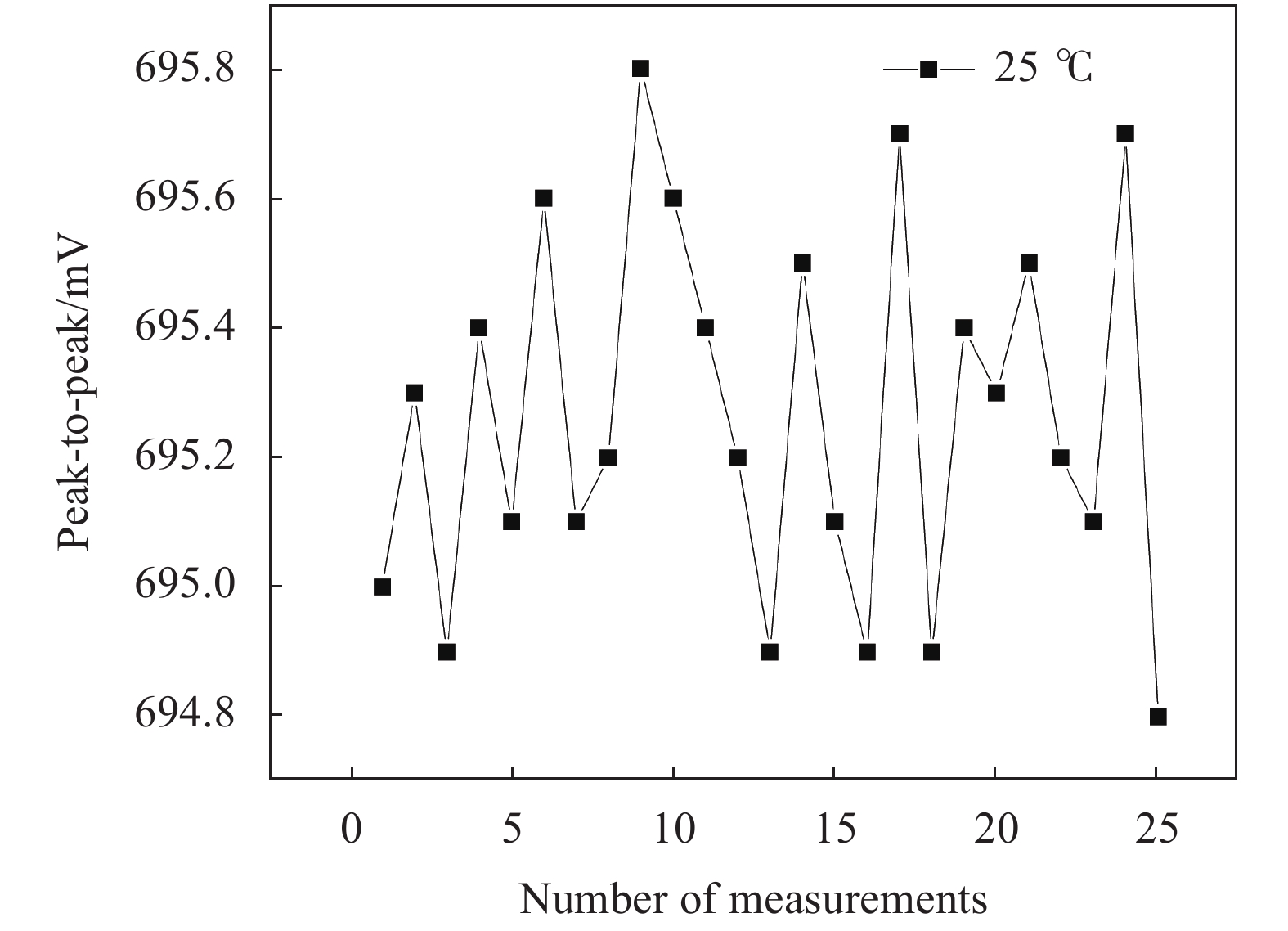

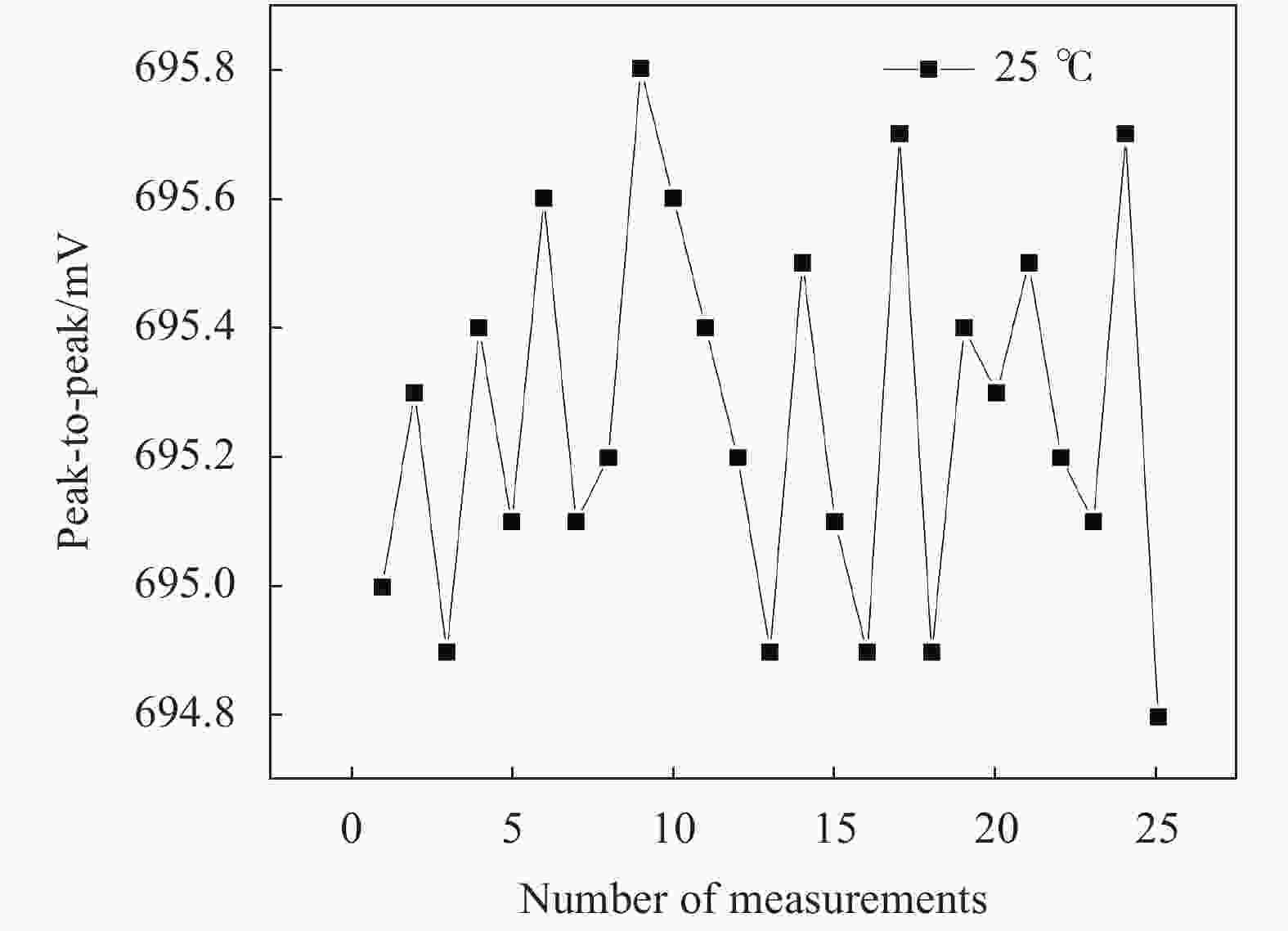

首先,在测试平台的环境下检测传感器性能的稳定性好坏。在密闭气室内充入浓度为10000 ppm的标准CO2气体,传感器接入上位机,持续工作12 h,每隔30 min保存一次数据,观测传感器采集峰峰值的波动情况,如图9所示。

-

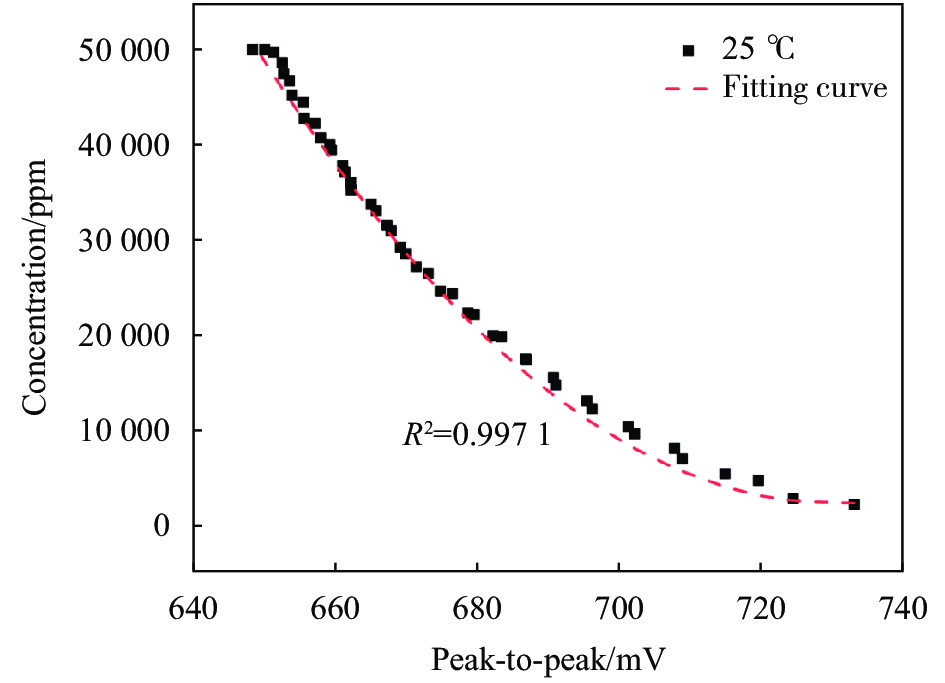

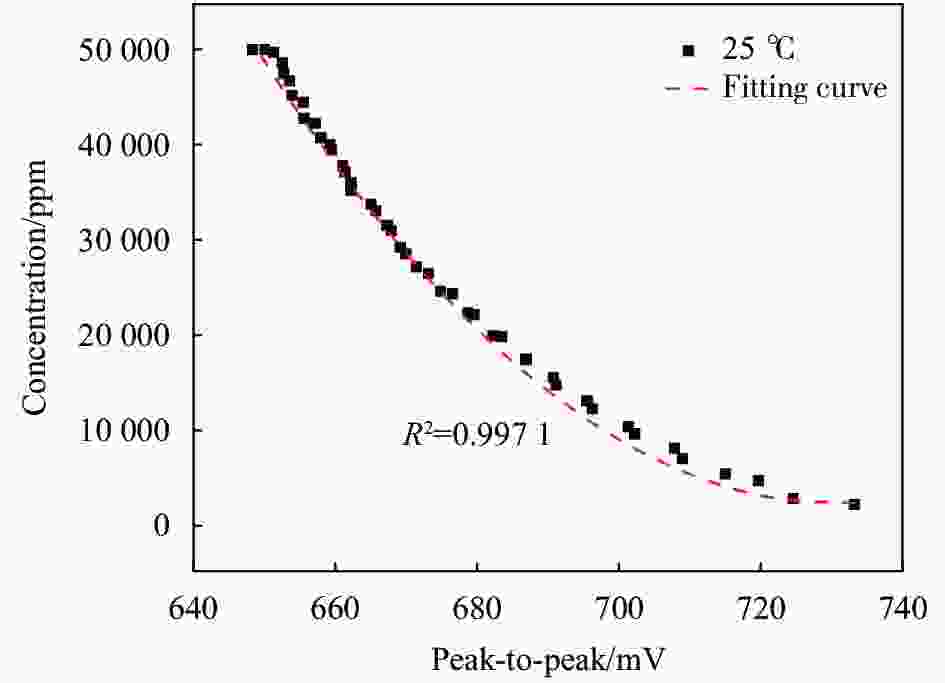

在实验开始之前,首先进行零点标定,利用真空泵将传感器内的气体抽出,密闭气室的注入气体通道接入纯氮气进行零点标定。然后将标气瓶中的浓度98%的标准气体经过气体分析仪器配置成标准的不同浓度的CO2气体,并依序分次注入密闭气室中。之后利用CO2传感器采集的峰峰值与注入的CO2浓度值之间的对应关系图,如图10所示,通过数据拟合得到25 ℃浓度拟合方程,如公式(2)所示。

方程为:

-

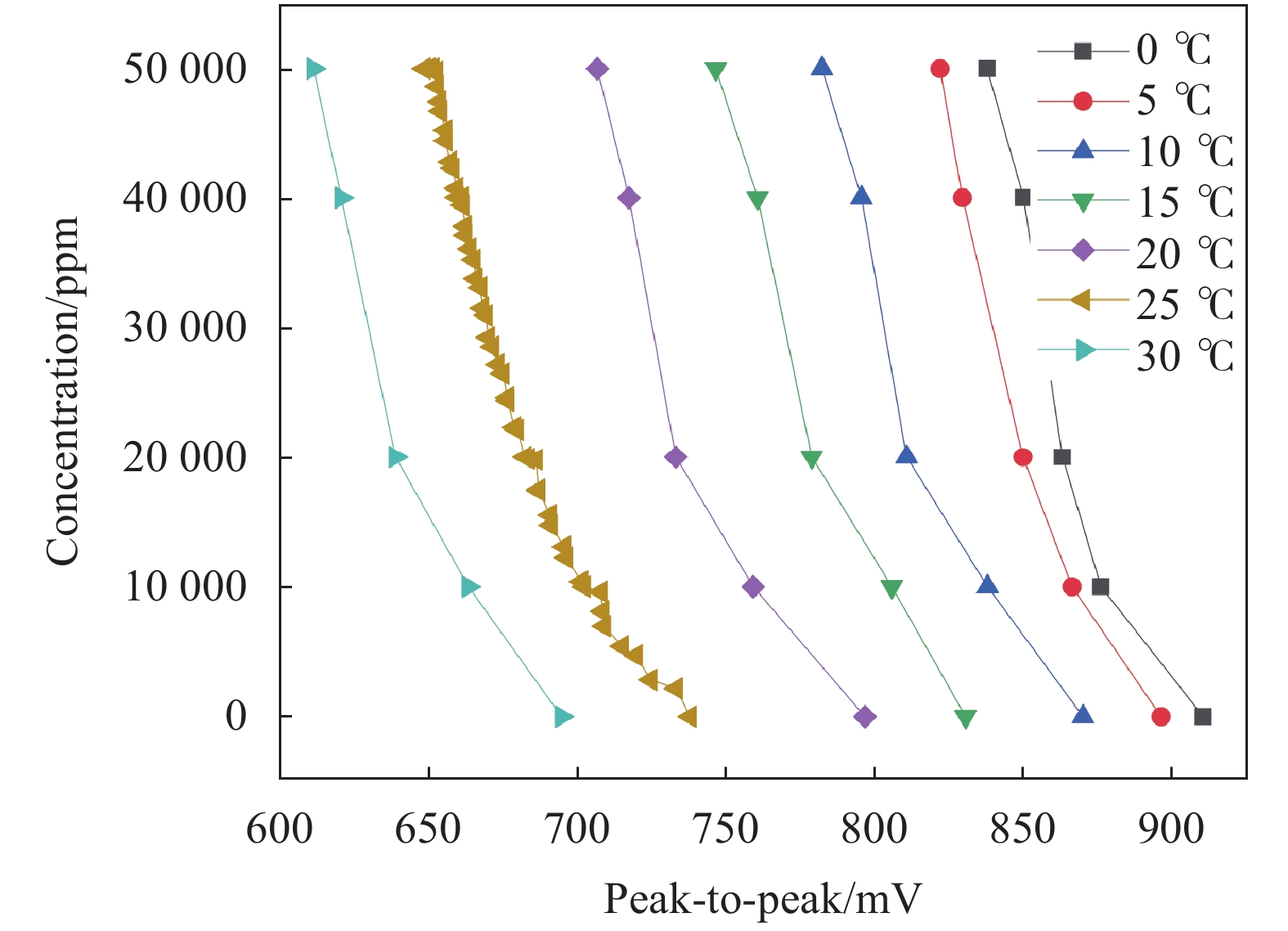

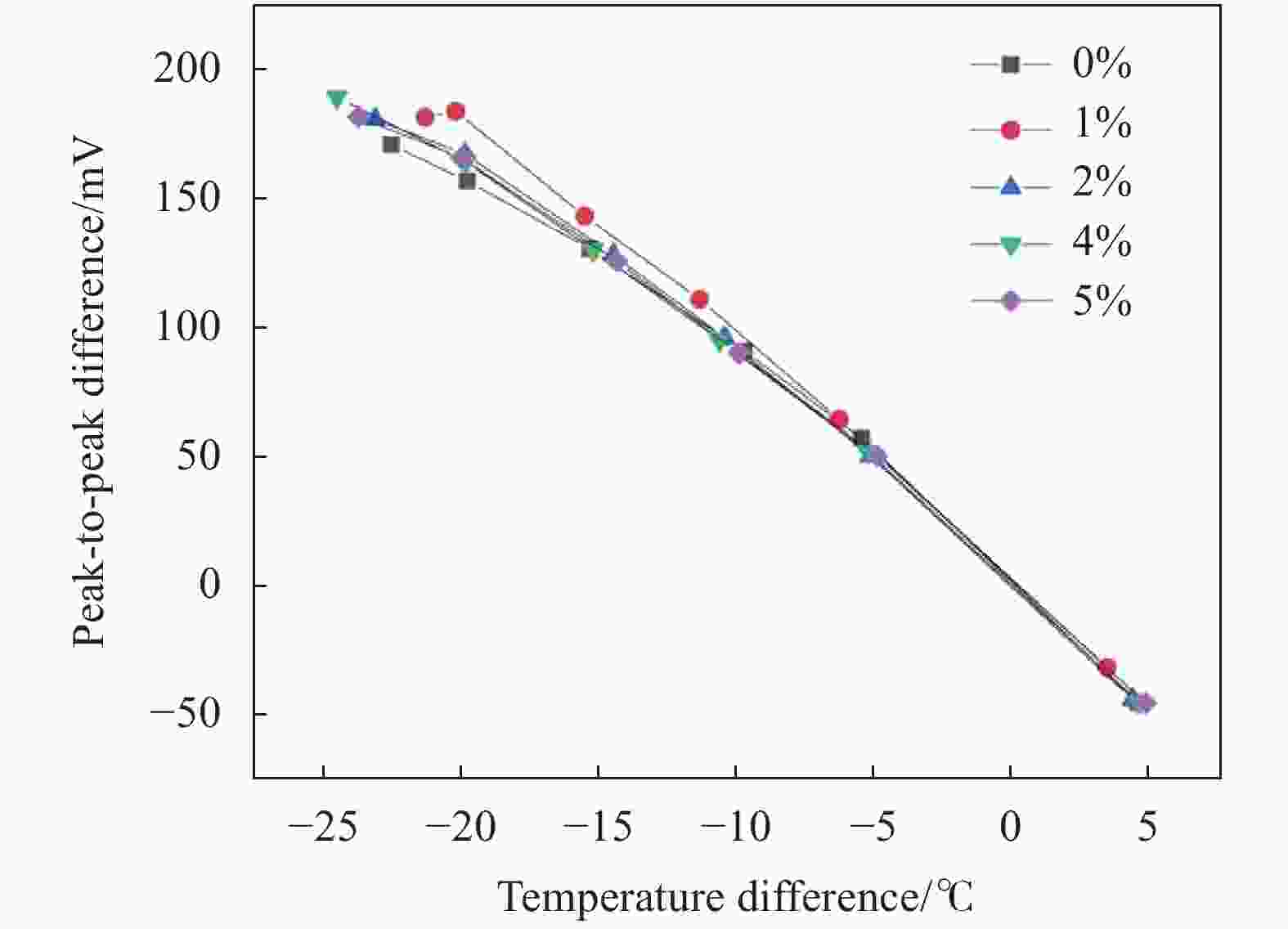

实验温湿度箱中的环境温度设置为可调温度分别为0、5、10、15、20、25、30 ℃,将标气瓶中的纯度0%、1%、2%、4%、5%的标准CO2气体注入密闭气室中。由于温湿度箱内空气流通较大,导致箱内不同位置的温度并不完全相同,所以温度值以温湿度传感器的输出值为准。采集温度传感器输出的温度值与CO2传感器的峰峰值,从而得到不同温度下的浓度值与峰峰值之间的关系,如图11所示。

Figure 11. Relationship between the concentration value and the peak-to-peak value at different temperatures

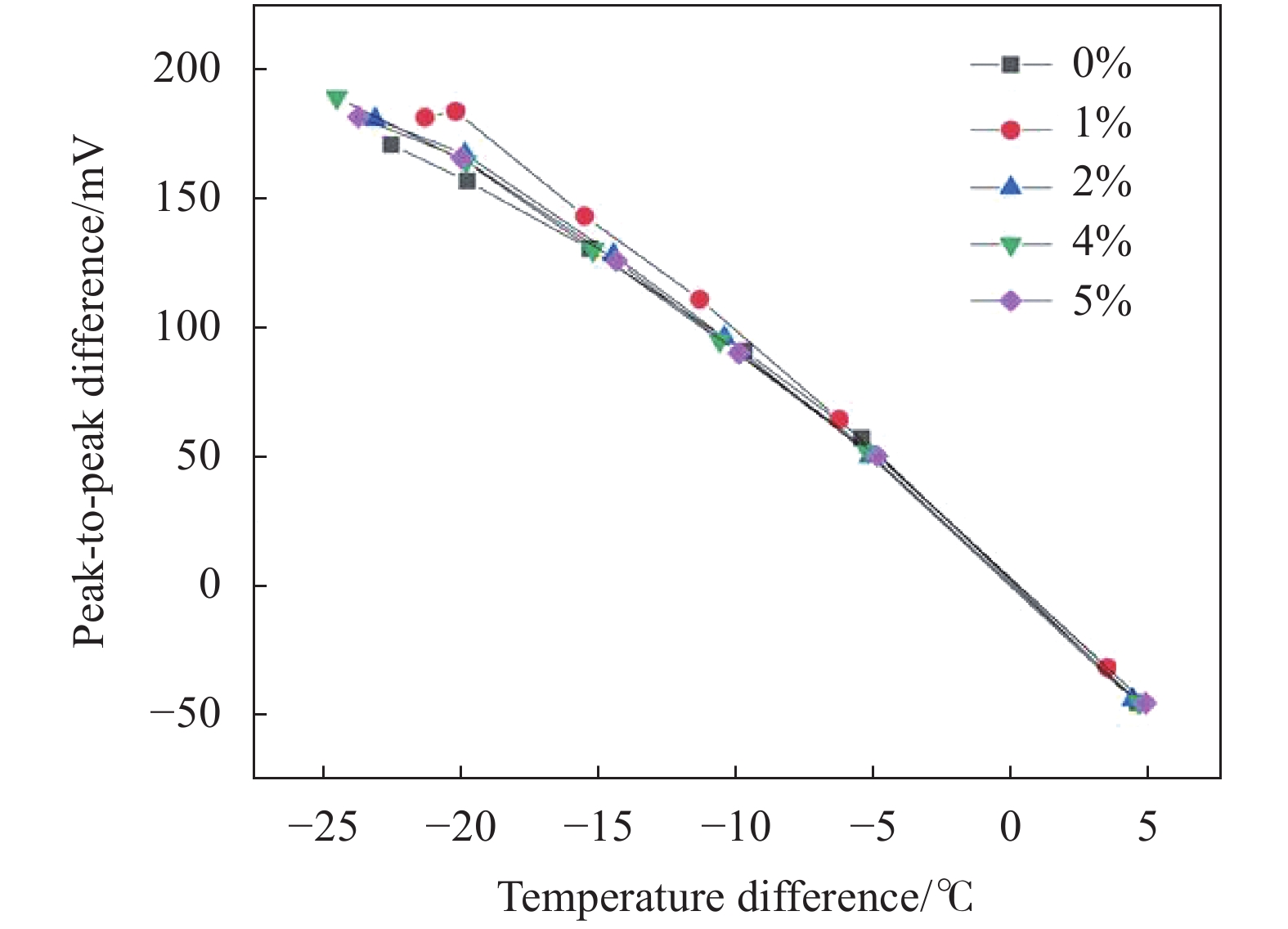

由上图可知,温度主要影响CO2的吸收率,进而影响峰峰值大小,当温度上升时,峰峰值降低,未补偿的情况下测量浓度值偏大。以25 ℃为标准,找寻同一浓度下的峰峰值差值与温度差值的关系,如图12所示。

可以注意到,各个浓度下的峰峰值差值和温度差值近似为一条曲线,符合温度对CO2吸收系数的影响关系与探测器对红外辐射的吸收率的影响关系[6, 9, 13]。故将图10所示曲线拟合为一条曲线,其方程(3)为:

将方程(3)代入方程(2)中,可以得到带有温度补偿功能的浓度计算方程。最终,将带有温度补偿功能的方程编写入STM32的程序中,再次测量,测量结果如表1所示。

Sample gas concentration/ppm Detection of concentration/ppm Absolute error/ppm Relative error 1800 1773 −27 1.5% 12000 11873 −127 1.05% 24000 24269 269 1.12% 30000 30725 725 2.4% 35000 36326 1326 3.7% Table 1. Duplicated testing results

Design of non-dispersive infrared CO2 sensor with temperature compensation

doi: 10.3788/IRLA20210746

- Received Date: 2021-10-11

- Rev Recd Date: 2021-11-29

- Publish Date: 2022-04-07

-

Key words:

- non-dispersive infrared(NDIR) /

- optical simulation of air chamber /

- signal processing circuit /

- temperature compensation concentration algorithm

Abstract: In recent years, the greenhouse effect has become more and more obvious. The side effects brought by increasing of CO2 concentration have seriously affected people's production and life, and are even closely related to everyone's healthy. In defect of the large size, portability, high precision, and modularity of CO2 commercial sensors currently, a pyroelectric-based non-dispersive infrared (NDIR) method measuring CO2 concentration system was designed. The system design was mainly divided into four parts: air chamber structure design, signal circuit design, software control design and data processing. The air chamber structure design adopted a single-channel structure design, which was optically simulated. Finally, the size of the air chamber was determined, which effectively improved the measurement accuracy of the system. In terms of signal circuit design, a small signal amplifying circuit based on the differential method was designed to extract and amplify the effective signal from the noise to increase resolution. The software control design employed digital filtering algorithm to filter out interference and clutter, extract the effective value in the data, and improve the signal-to-noise ratio. In view of data processing, a gas test platform was built, and the temperature and humidity and peak-to-peak compensation formulas were used to compensate for the influence of temperature on the peak-to-peak value. Then, the gas concentration value was calculated using the curve fitting method at 25 ℃, and finally output through the serial port. After testing, the measurement range of the system is 5%, and the relative error is within 1500 ppm, which can meet the safety requirements of fire alarm, underground and other occasions monitoring.

DownLoad:

DownLoad: