-

激光制孔具有高效率、高精度、无机械应力及无工具损耗等优点,已经成为现代微小孔加工领域的关键技术之一[1]。飞秒激光作为时域脉冲宽度在飞秒量级的激光,其功率密度极高,近年来不断被国内外诸多学者研究和开发,开始广泛应用于各类微加工领域[2-5]。同时,飞秒激光加工过程中存在效率过低的问题,难以实现高速微加工[6],凭增加激光器功率可提高激光的烧蚀效率,但会伴随等离子体堆积引起的屏蔽效应、局部热损伤和熔渣去除困难等负面影响[7]。

研究表明,水辅助激光打孔可以改善打孔的质量[8-9]。Zhai等[10]采用纳秒脉冲激光对镍基合金进行了激光打孔研究,比较了空气环境和水环境中的微孔加工效果。通过分析比较结果发现环境介质对激光打孔的形貌有明显的影响,水环境下孔外表面无飞溅物堆积。Chen等[11] 在空气和水下对氮化硅陶瓷进行了纳秒脉冲激光制孔实验,研究了激光扫描速度和加工环境对孔锥度的影响。结果表明,水下激光打孔对孔锥度的影响比空气中明显,在固定扫描速度下,锥度随孔深增加而减小,在相同孔深下,锥度随着扫描速度的降低而减小;同时水下激光制孔可以获得较好的孔壁加工质量。Feng等[12]用皮秒激光在水下对氧化锆进行了激光打孔,系统研究了工艺参数对孔几何质量的影响。发现水环境有利于减少孔内壁裂纹,降低孔内壁表面粗糙度,降低打孔过程中激光对孔周围材料力学性能的影响。Wang等[13]对比了有无水辅助条件下,磁场辅助激光在镁合金上打孔质量的变化。发现水下激光加工的孔洞质量更高,水介质可以有效地减少孔口处的氧化物碎屑堆积和孔内壁的重铸层厚度。Wang等[14]研究了水辅助对飞秒激光4H-SiC材料制孔的影响,实验发现,通过水在孔内部的冲刷和扩散作用,可以消除空气条件下微孔出现的入口碎屑再沉积、裂纹、表面材料脱落、热影响区和重铸层等现象。

综上,为了进一步改善飞秒激光制孔质量,国内外研究学者提出了水辅助方法,该方法可以有效减少微孔出入口碎屑、内壁微裂纹、重铸层和热影响区等缺陷。但大部分只对某一种水辅助方法进行了研究,没有开展不同水辅助方法的对比分析,同时,工件在水中的不同位置也会影响到水介质何时开始介入到激光与材料的作用过程。目前的水辅助激光加工依旧存在静态水介质会受到材料碎屑污染而变浑浊,动态水介质的水面大范围波动会影响激光的折射、透射效果等问题。为了进一步优化水辅助飞秒激光制孔方法,文中搭建了水辅助飞秒激光逐层逐圈切孔系统,对比分析了在不同激光脉冲重复频率下,水基辅助和水膜辅助对飞秒激光逐层逐圈切孔微孔出入口直径、锥度、内壁形貌和内壁粗糙度的影响。文中研究对比了两种水辅助方式(试样上方没有水和试样下方没有水)对飞秒激光制孔质量的影响,为水辅助飞秒激光制孔工艺的优化实验研究提供了技术支持,为水辅助飞秒激光制孔的工业应用提供一定的参考。

-

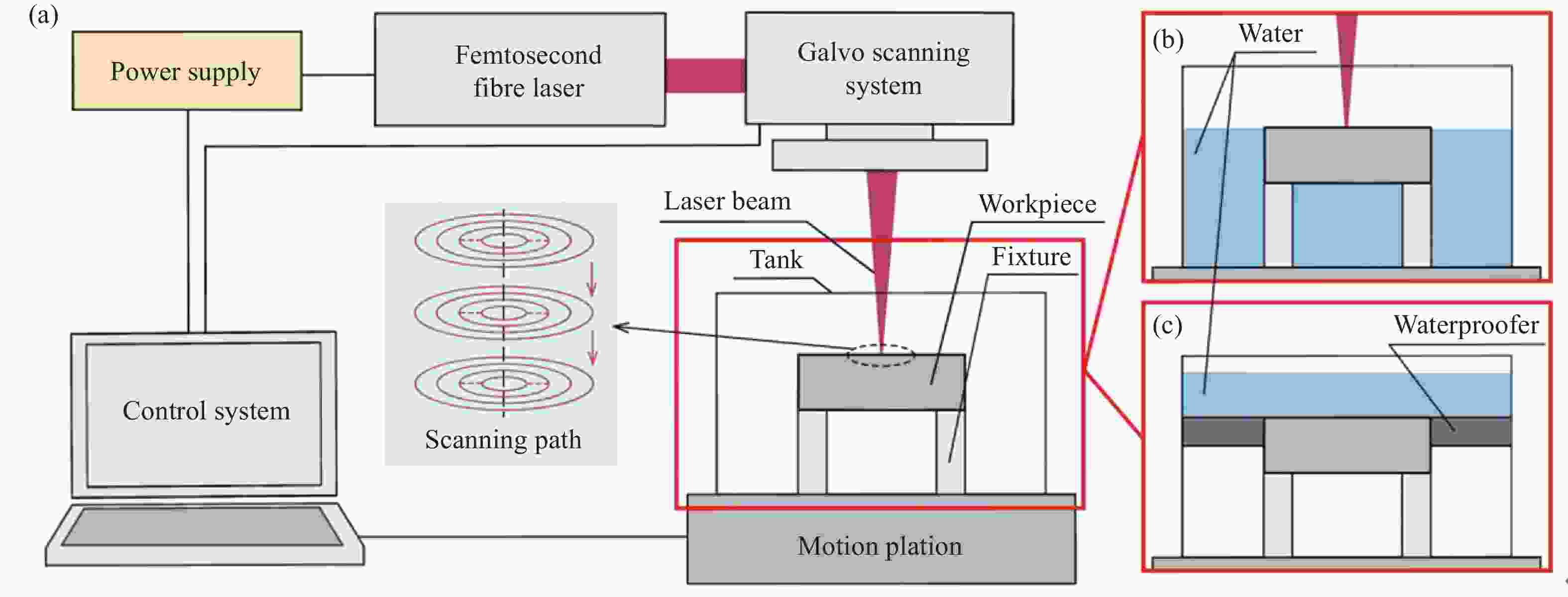

文中实验采用的水辅助飞秒激光逐层逐圈切孔系统如图1所示,主要由电源、飞秒光纤激光器、光学模组系统、运动控制平台和控制系统构成。通过控制系统控制光学模组和运动平台,可以实现逐层逐圈的激光扫描路径。实验主要研究了水基辅助激光制孔和水膜辅助激光制孔两种水辅助情况,并同时与工件在空气中的加工效果做对比。在水基辅助条件下,水面应尽量与工件上表面持平,如图1 (b)所示,这是为了保证孔被打通后水介质能上溢到通孔内部,充分参与后续激光制孔过程,对微孔的几何形貌和内壁质量产生影响。水膜辅助条件如图1 (c)所示,通过隔水层结构将水限制在工件上表面,形成一层厚度在1 mm左右的水膜,工件下表面与空气接触。

Figure 1. Schematic diagram of water-assisted femtosecond laser layered-ring trepanning system. (a) In air; (b) Water-based; (c) Water film

实验所用装置为高功率飞秒激光微纳加工系统(Active Fiber Systems GmbH, Germany, UFFL_1030_EXTAOM),实物图如图2所示。该系统的光纤激光器系统发出的激光束中心波长为1030 nm,重复频率为50 kHz~19.12 MHz,光束质量M2<1.25,出口光斑直径约为3 mm,最大脉冲能量为160 μJ,脉冲持续时间为262 fs~10 ps。装置光路中同时配备扫描振镜(SCANLAB, Germany, IntelliSCAN 14Ⅲ)及Helical旋光模组系统,实验使用的是扫描振镜模组系统,系统的最大扫描速度可达2 m/s,可实现80 mm×80 mm的单次最大扫描辐面。该系统具有较高的精度,在计算机软件的控制下可达到X轴±0.75 μm/200 mm;Y轴±0.75 μm/600 mm;Z轴±0.75 μm/100 mm;A轴0.001°;B轴0.001°的重复定位精度。光纤激光器发出的激光各种参数也可以通过计算机软件调整。

-

实验开始前先制备工件样品,实验中使用的GH4220镍基高温合金由东莞市腾锋金属材料有限公司生产,化学成分如表1所示,可以直接购买。首先,通过线切割加工方式将母材棒料切割成初始工件样品,并预留一定的磨抛余量;然后,使用金相磨砂机配合水磨砂纸去除线切割留下的划痕(一般磨至1000~1200目左右即可,避免表面过于光亮增大反射率),直至样品厚度达到1 mm左右;之后,将样品放入烧杯中使用超声波清洗机清洗5 min (清洗液为无水乙醇),去除表面碎屑和污垢;最后,取出样品在空气中干燥,封装标记备用。

Composition Cr Ni Co W Mo Al Ti V Mass fraction 9%-12% Allowance 14%-15.5% 5%-6.5% 5%-7% 3.9%-4.8% 2.2%-2.9% 0.25%-0.8% Composition C Fe B Ce Mg Mn Si P Mass fraction ≤0.08% ≤3% ≤0.02% ≤0.02% ≤0.01% ≤0.5% ≤0.35% ≤0.015% Composition S Cu Pb As Sn Sb Bi — Mass fraction ≤0.009% ≤0.07% ≤0.001% ≤0.002 5% ≤0.001 2% ≤0.002 5% ≤0.000 1% — Table 1. Chemical composition of nickel-based superalloy GH4220

实验中为保证水辅助条件下水面的高度能达到设计要求,可以在计算水箱的容积后,加入符合要求的水量(水介质为普通纯净水)。激光在工件上的扫描路径为一定数量的同心圆,相邻圆之间的半径差保持一致,最外层圆的直径为300 μm。加工完一层后,激光束下移加工下一层,直至整个加工过程结束,从而实现逐层逐圈的加工效果。具体工艺参数如表2所示,该参数可以保证微孔在空气条件下具有一定的出口直径,从而使后续水基辅助实验中,水介质可以及时参与激光制孔过程,每组参数重复3次,每个孔的制造时间在80 s左右。

Laser pulse duration/

fsLaser spot

diameter/μmPulse repetition

rate/kHzScanning

speed/mm·s−1Singer laser pulse

energy/μJFeed distance/

mmFeed rate/

μm·layer−1276 30 50-300 50 80 1 20 Table 2. Specific parameters used in the experiment

实验结束后,需要对样品进行多步处理,获取更多实验数据。首先,用绸布简单擦拭样品,通过基恩士激光共聚焦显微镜(CLSM)对孔出入口的几何形貌进行测量并计算锥度;然后,通过金相磨砂和抛光机磨抛出微孔截面(研抛过程中应同样保持对样品的超声清洗,避免磨粒和碎屑堵塞微孔,划伤内壁),通过CLSM和对孔截面的形貌和孔内壁的表面粗糙度进行表征和测量,通过可变真空钨灯丝扫描电镜(SEM)对孔内壁质量进行表征;最后,对抛光后达到镜面效果的孔侧壁进行金相组织腐蚀处理,腐蚀后通过无水乙醇和清水洗去样品上的腐蚀液,在CLSM最高倍数下未发现重铸层,故不在后续文字中分析。

-

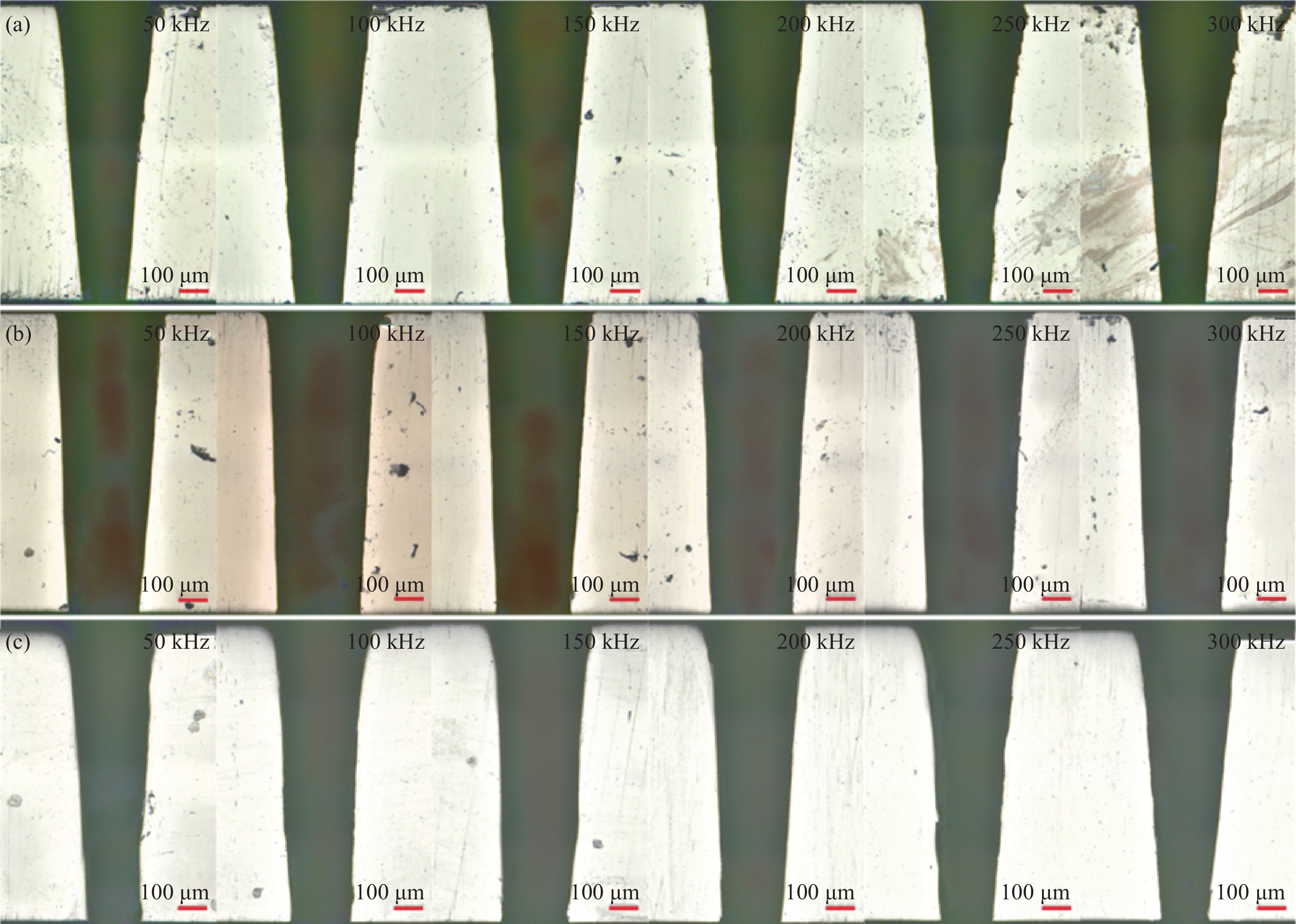

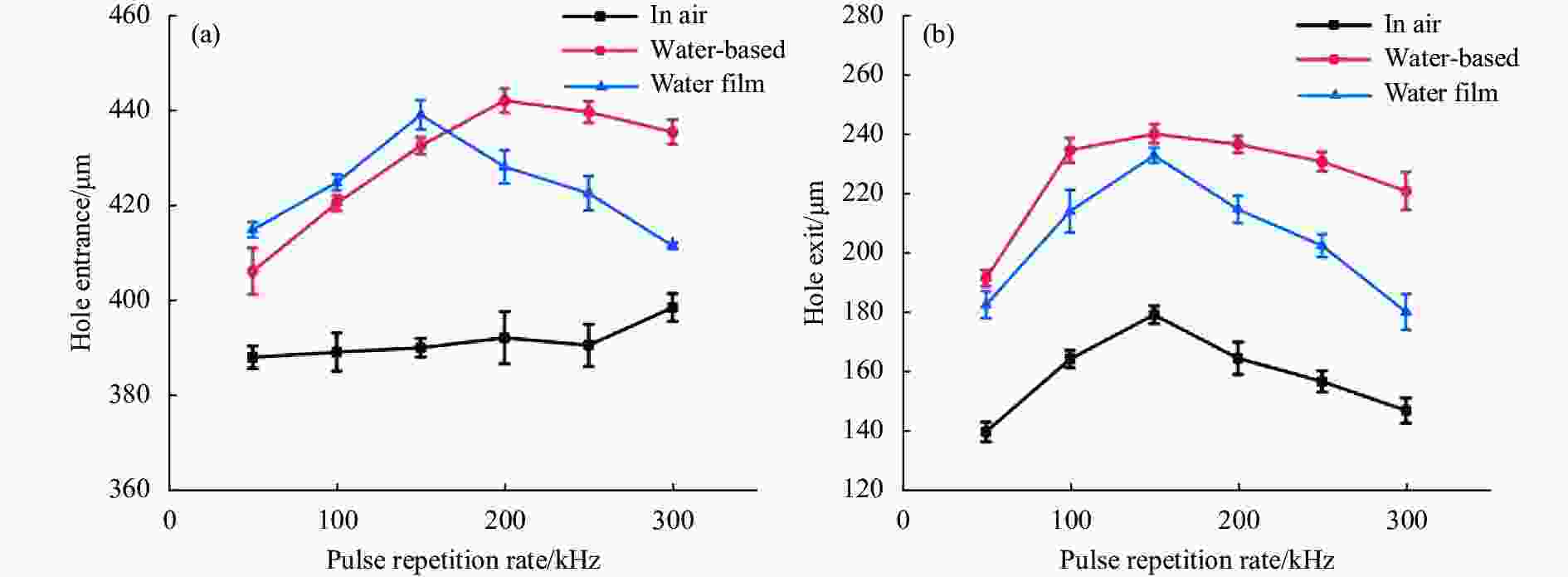

图3显示了空气和不同水辅助飞秒激光制孔的入口和出口形貌。结合图4可以看出,水基和水膜辅助飞秒激光加工高温合金时,孔的入口和出口直径相较于空气中的都有所增加,且出口增加较为明显。当脉冲重复频率为50 kHz、100 kHz和150 kHz时,此时水膜辅助情况下的微孔入口直径要大于水基辅助,这是因为水膜辅助情况下,刚开始加工激光就与水介质相互作用,在水介质的作用下,微孔入口直径增加;而水基辅助情况下,当微孔被打通后激光才会与水介质相互作用,水介质对微孔入口的影响要小于水膜辅助,从而导致入口直径小于水膜辅助。当脉冲重复频率不断增加,重复频率为200 kHz、250 kHz和300 kHz时,水膜辅助情况下的微孔入口直径要小于水基辅助,这是因为水膜辅助情况下,水介质的总量较少,随着脉冲重复频率的增加,单位时间内作用到水膜上的脉冲个数增加,单位时间内水膜吸收更多的能量,更多的水分被蒸发掉,从而导致水介质对材料去除的促进效果降低,水膜中水分的蒸发量增加,导致入口直径越接近于空气情况。水基辅助情况下,水介质的蒸发量相对于水介质的总量而言较小,随着脉冲重复频率的增加,水介质依然可以较好地促进飞秒激光加工中材料的去除。对于出口直径,水基辅助要大于水膜辅助,这是因为水基辅助情况下,当微孔被打通后,水介质直接与试样下表面接触,而水膜辅助情况下,一开始水介质并不与试样下表面接触,只有当微孔被打通后,渗入的水介质才有可能与试样下表面接触,且水量较少。所以水基辅助情况下,水介质对试样下表面材料的去除影响较大,微孔出口直径较大。

Figure 3. The morphology of the hole entrance/exit at different pulse repetition frequencies. (a) In air; (b) Water-based; (c) Water film

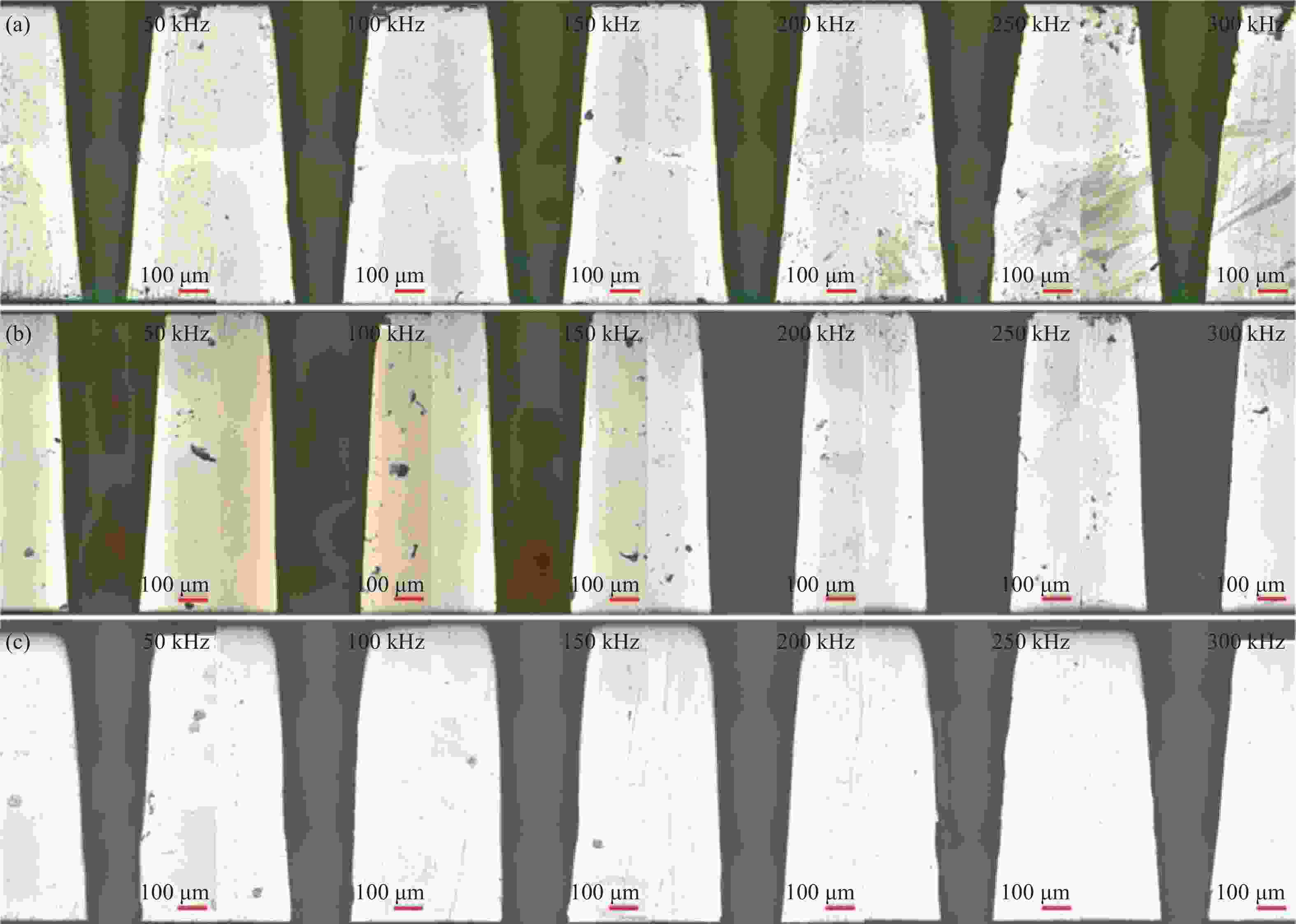

Figure 5. Hole sidewall morphology at different pulse repetition rates. (a) In air; (b) Water-based; (c) Water film

图3中还可以发现水基和水膜辅助飞秒激光制孔的入口处存在一圈激光烧蚀区域,且水膜辅助时烧蚀面积更大。这是由于水增强了激光诱导等离子体产生的冲击波[15],冲击波作用于工件表面,促进了熔融物和碎屑去除,一定程度上扩大了烧蚀区域。同时,相较于空气,水有效地抑制了激光诱导等离子体的膨胀,高密度的水下等离子体与工件表面交换热量,增大了烧蚀面积。随着重复频率的增大,水膜不断吸热蒸发,水膜辅助下孔入口处的激光烧蚀区面积不断减少。

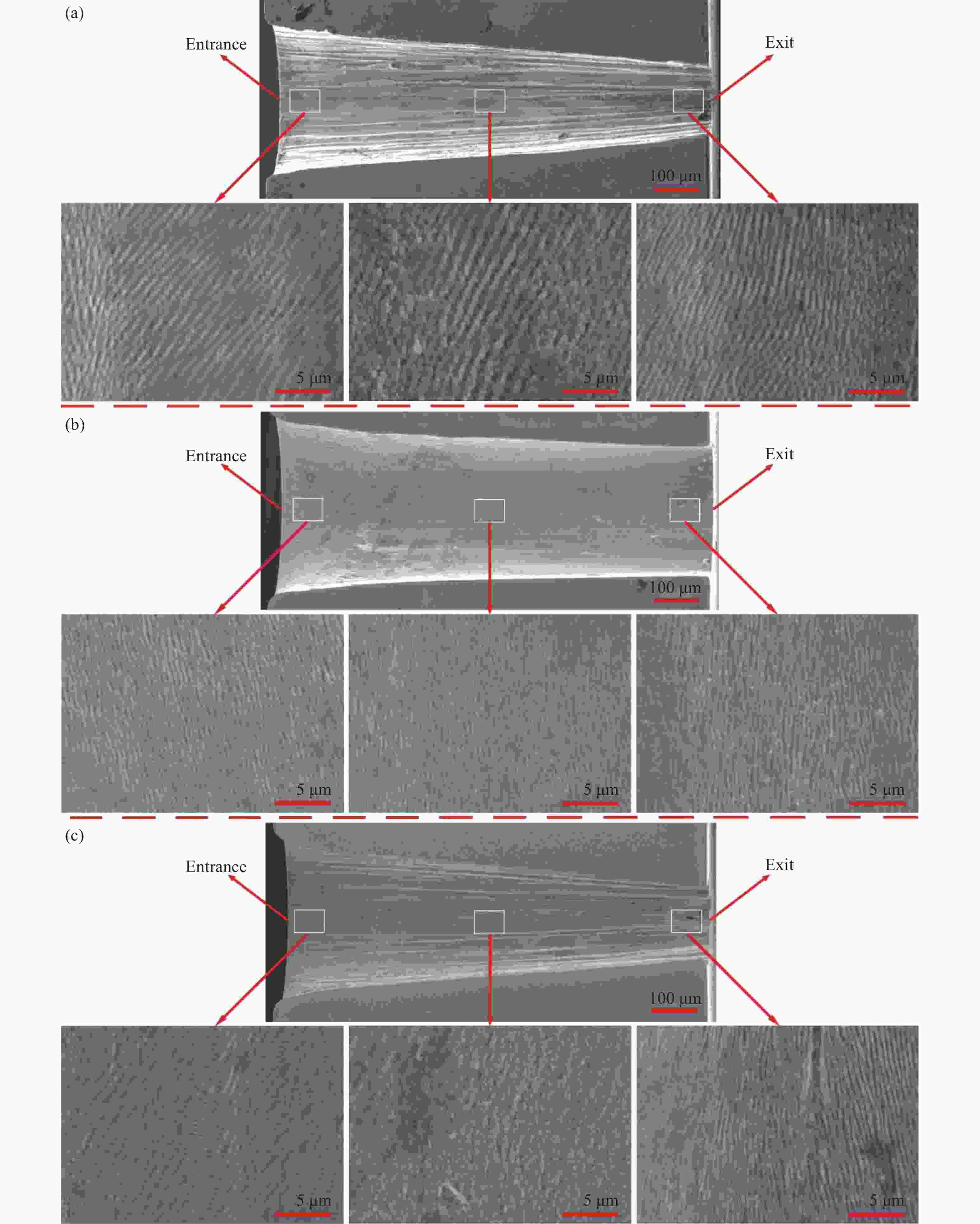

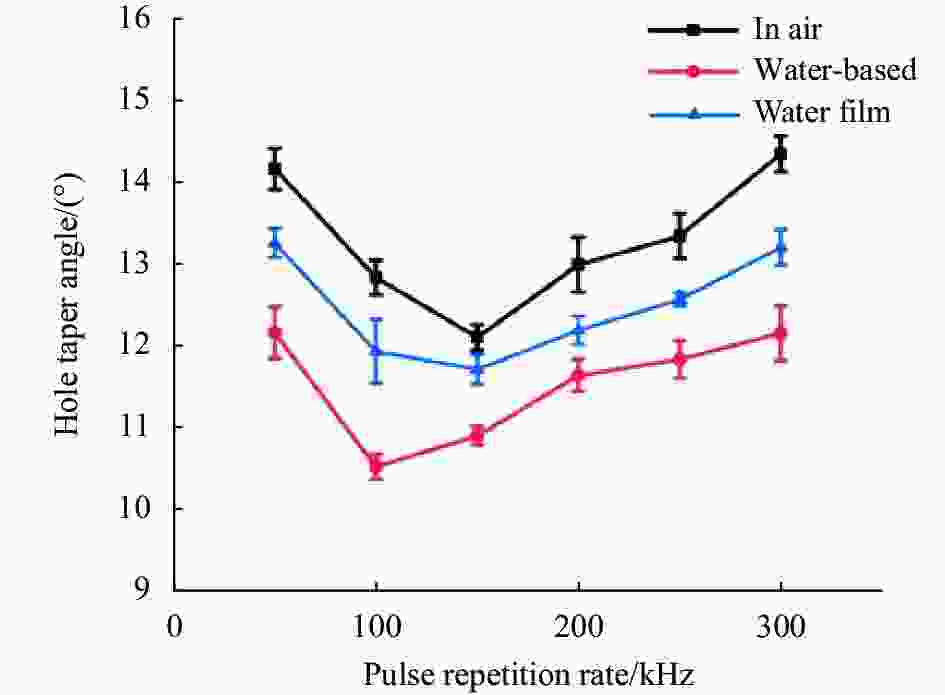

图5显示了空气和不同水辅助条件下飞秒激光制孔的侧壁形貌。结合图6可以发现,水基辅助时制孔的材料去除率最高,锥度最小;空气中制孔的材料去除率最低,锥度最大;水膜辅助时制孔的去除率和锥度介于两者之间。飞秒激光在空气中加工高温合金时,孔内形成的等离子体羽流吸收激光能量降低能量密度,减少了激光对材料的去除效率。在水基条件下,孔打通后底部存在水流上溢现象,一方面水流受热后的汽化作用会驱动等离子体羽流向上扩散,为孔内碎屑和烧蚀材料的排出提供更多动力[16];另一方面,水流受热形成气泡,气泡上浮破裂形成的压力进一步促进碎屑的排出。同时,等离子体在水和水汽中的大小比在空气中要小,孔内的等离子羽流被约束,更多的激光能量作用于材料上,提高了激光对材料的去除效率。水膜辅助时受热的水层虽然同样可以促进碎屑排出,约束孔内的等离子体羽流,但由于激光穿过水层过程中部分能量会被水层吸收和散射,因此,材料去除效率要小于水基辅助,孔的锥度也更大。随着重复频率的增加,工件上的热累积效应快速增强[17],激光作用于孔内材料上而产生的等离子体逐渐增多,等离子体对激光能量的屏蔽效应逐渐增强,导致高重复频率下激光对材料的去除效率降低,因此,3种条件下孔的锥度都随着重复频率的增大先减小后增大。同时,两种水辅助方式下孔的出入口直径均大于空气条件,且水基条件下孔的出口直径还要大于水膜条件,这导致了两者的孔锥度均小于空气条件,水基条件下孔的锥度最小。

不同脉冲重复频率时两种水环境与空气条件下激光制孔的孔径和锥度改善情况如表3所示。可以发现,与空气条件下对比,不同脉冲重复频率时,水基辅助激光制孔的孔入口直径增加了4.67%~12.73%,出口直径增加了34.02%~50.38%,锥度减小了9.93%~18.04%;水膜辅助激光制孔的孔入口增加了3.27%~12.59%,出口直径增加了22.62%~30.64%,锥度减小了3.24%~7.96%。

Pulse repetition rate/kHz 50 100 150 200 250 300 Hole entrance Water-based 4.67% 8.05% 10.93% 12.73% 12.59% 9.29% Water film 6.91% 9.19% 12.59% 9.18% 8.20% 3.27% Hole exit Water-based 37.07% 42.86% 34.02% 43.82% 47.29% 50.38% Water film 30.64% 30.36% 29.99% 30.49% 29.21% 22.62% Hole taper angle Water-based −14.15% −18.04% −9.93% −10.45% −11.34% −15.29% Water film −6.40% −7.07% −3.24% −6.19% −5.84% −7.96% Table 3. Improvement of hole diameter and taper under different pulse repetition rates using two water-assisted methods compared with air conditions

-

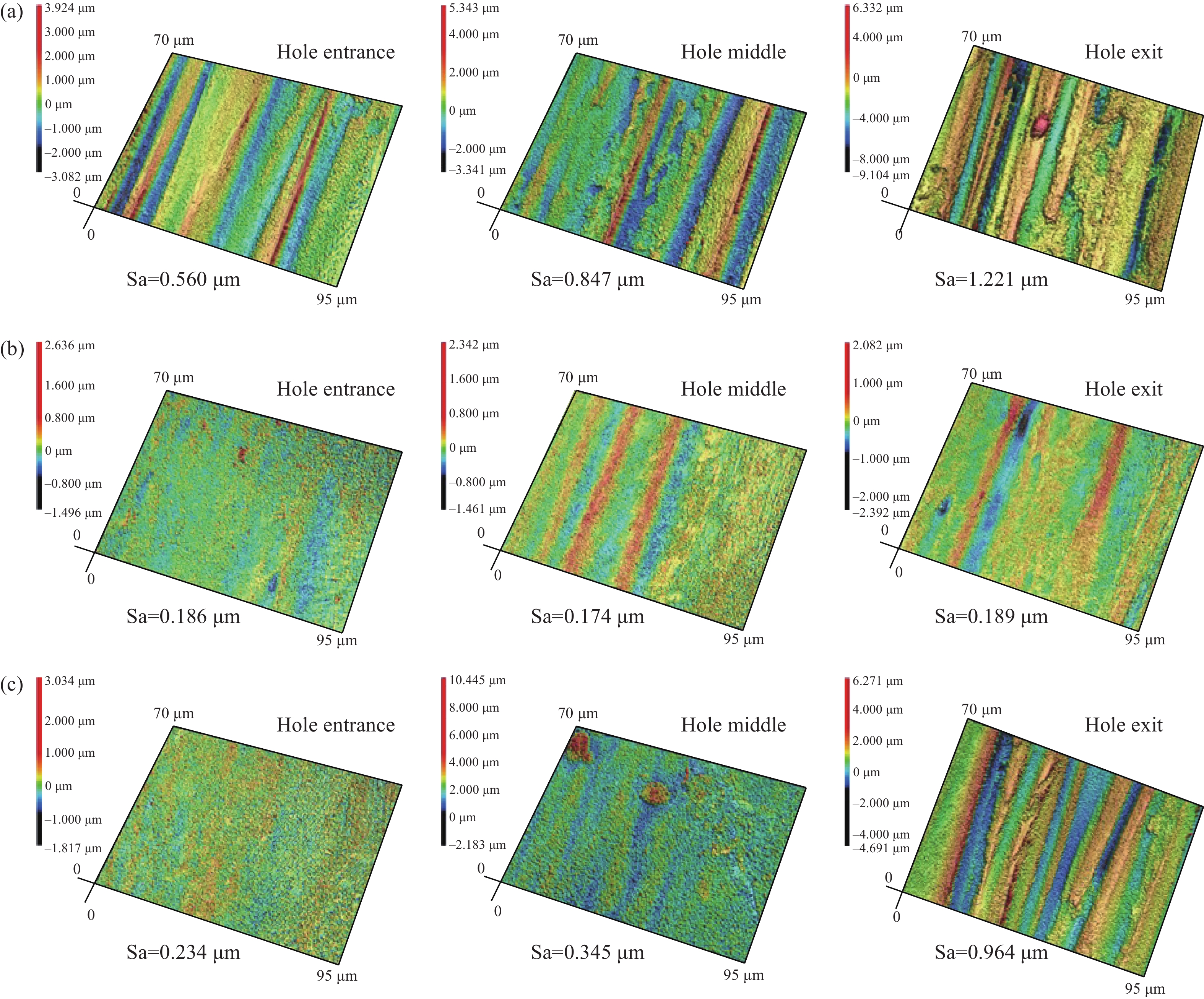

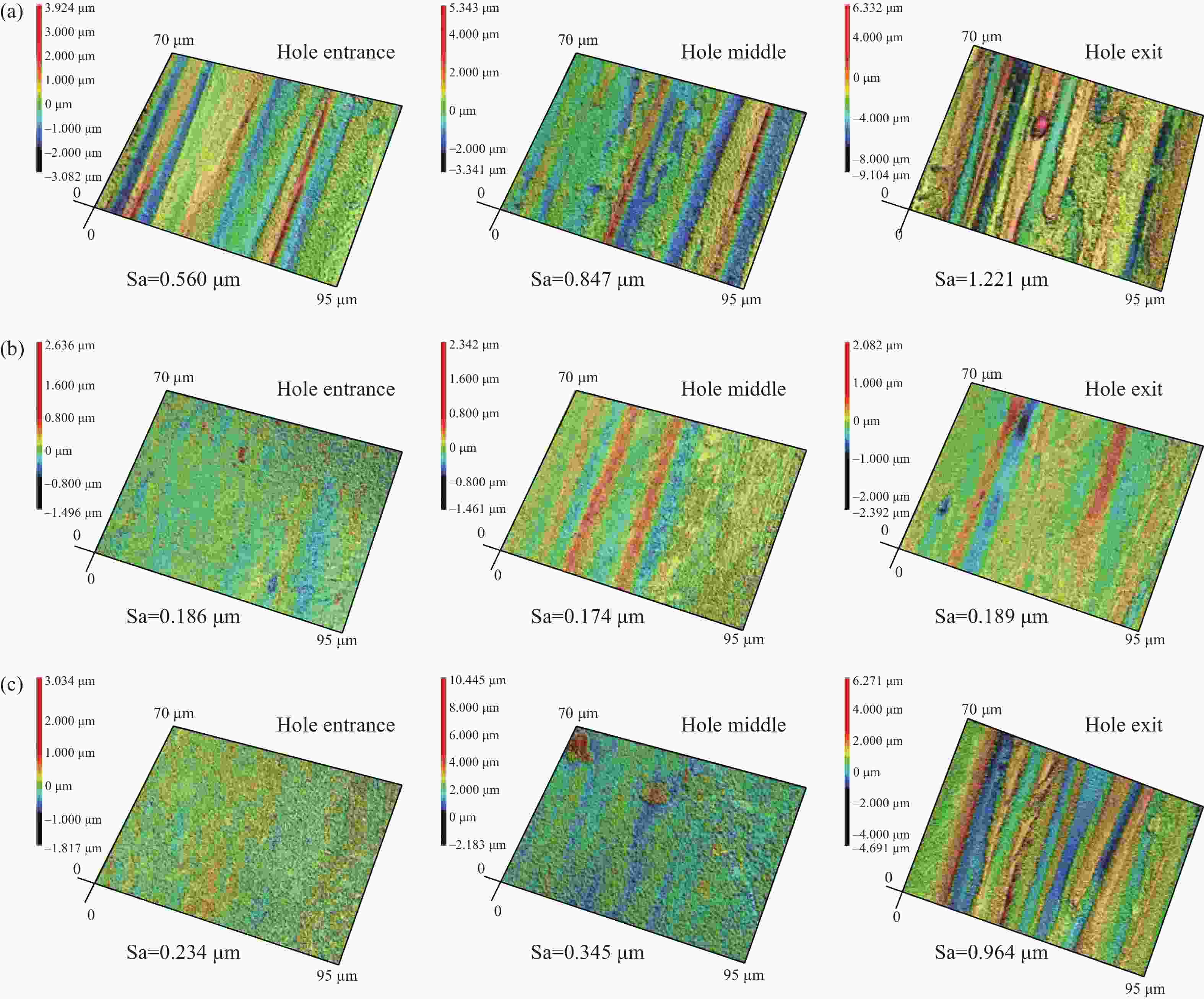

图7显示了激光脉冲重复频率在300 kHz时,空气和不同水辅助条件下飞秒制孔内壁入口、中间和出口处的三维形貌。可以发现水膜辅助和空气条件下,测量位置越接近孔出口,孔内壁形貌越不光整,粗糙度越大,且水膜辅助时孔内壁质量整体好于空气条件下;水基辅助时孔内壁质量最好,且孔不同区域内壁的粗糙度数值波动不大,整体形貌较为平整。图8为激光脉冲重复频率在300 kHz时,空气和不同水辅助条件下飞秒制孔截面的SEM图。可以发现:高重频时,孔内壁存在明显的激光诱导表面微织构,其周期结构与飞秒激光的偏振方向有关[18]。两种水辅助均可改善孔内壁上由于激光诱导产生的表面微织构,且水基辅助的改善效果更明显。

Figure 7. CLSM 3D morphology for different inwall locations of the hole at laser pulse repetition rate of 300 kHz. (a) In air; (b) Water-based; (c) Water film

Figure 8. SEM observation for hole sections at laser pulse repetition rate of 300 kHz. (a) In air; (b) Water-based; (c) Water film

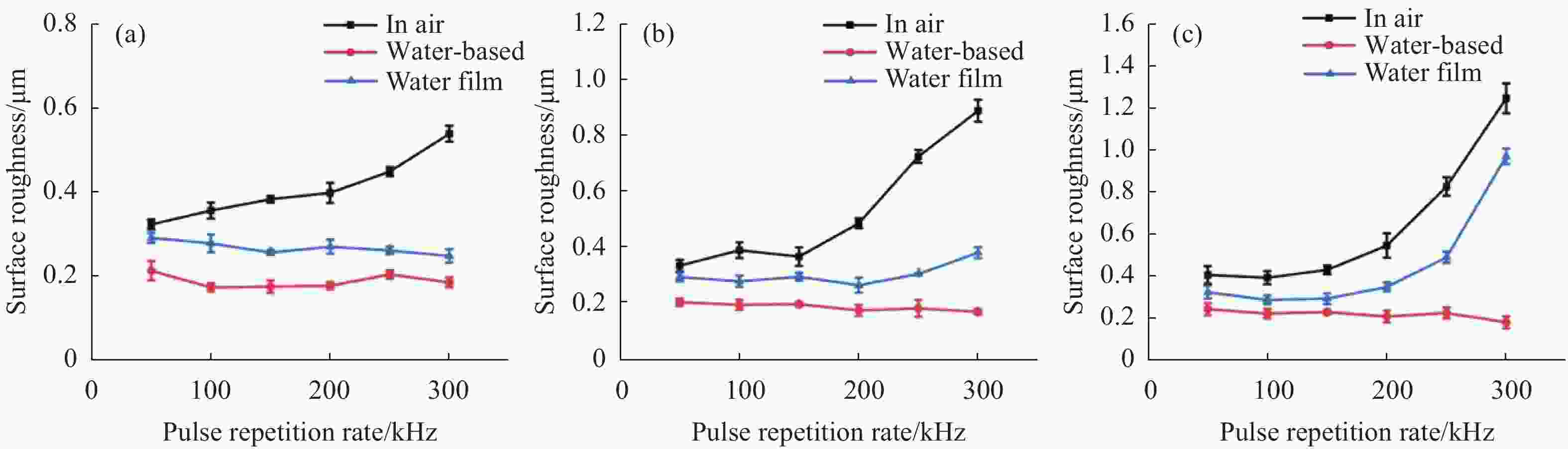

图9显示了不同水辅助和空气条件下,微孔内壁不同区域粗糙度数值随着激光脉冲重复频率增加的变化曲线。可以发现,随着重复频率的增加,空气中的内壁粗糙度不断增大;水基中内壁的粗糙度变化不大,且数值较低。这是由于飞秒激光在水中的空化效应产生空泡,空泡的急速产生、扩张和溃灭,在液体中产生激波或高速微射流[19-21],引起局部液体爆炸[22],从而使材料受到冲击,内壁去除得更加均匀,整体形貌更光整[23]。水膜辅助时,随着重复频率的增加,刚开始孔内壁粗糙度变化不大,当重复频率增加到一定程度时,孔内壁中间和出口处的粗糙度开始增大。这是由于重复频率增大后,水膜的汽化加快,激光在水中的空化效应只在加工初期出现,当水膜被击穿后,孔的加工条件变成了在空气中,导致孔中间和出口处的内壁质量变差。

不同脉冲重复频率时两种水环境与空气条件下激光制孔的孔内壁粗糙度改善情况如表4所示。可以发现,与空气条件下对比,不同脉冲重复频率时,水基辅助激光制孔的孔内壁入口粗糙度减少了33.95%~65.56%,中间粗糙度减少了38.64%~80.49%,出口粗糙度减小了39.95%~85.43%;水膜辅助激光制孔的孔内壁入口粗糙度减少了9.88%~53.89%,中间粗糙度减少了12.09%~57.61%,出口粗糙度锥度减小了20.10%~40.65%。

Figure 9. Effect of laser pulse repetition rate on the hole sidewall roughness. (a) Hole entrance; (b) Hole middle; (c) Hole exit

Pulse repetition rate/kHz 50 100 150 200 250 300 Hole entrance Water-based −33.95% −51.26% −54.17% −55.39% −54.44% −65.56% Water film −9.88% −21.85% −33.07% −32.08% −41.78% −53.89% Hole middle Water-based −38.64% −49.49% −45.82% −63.47% −74.49% −80.49% Water film −12.09% −28.17% −19.41% −45.10% −57.61% −56.84% Hole exit Water-based −39.95% −43.29% −46.53% −61.68% −72.62% −85.43% Water film −20.10% −26.84% −31.71% −35.95% −40.65% −22.10% Table 4. Improvement of hole sidewall roughness under different pulse repetition rates using two water-assisted methods compared with air conditions

-

文中实验研究了不同激光脉冲重复频率下,水基和水膜两种水辅助飞秒激光制孔方式对微孔几何形貌与孔壁质量的影响,为水辅助飞秒激光制孔工艺的优化提供了参考。可以得出以下结论:

(1) 相较于空气条件下,两种水辅助方式均可增加GH4220高温合金飞秒激光制孔的孔出入口直径,减小孔的锥度,提高微孔内壁质量,且水基方式下微孔的质量整体更好。

(2) 当激光脉冲能量为80 μJ,脉冲重复频率在100 kHz左右时,水基辅助飞秒激光制孔可以获得较好的内壁质量,同时相比于空气条件下孔的锥度减少了18.04 %。

(3) 随着飞秒激光脉冲重复频率的增加,微孔的入口直径在空气条件下略微增大,在两种水辅助条件下均先增大后减小,出口直径在3种条件下均先增大后减小;微孔的内壁粗糙度在水膜辅助和空气条件下不断增加,在水基辅助条件下变化不大。与空气条件对比,当脉冲重复频率达到300 kHz时,水基辅助条件可以使微孔出口处的内壁粗糙度减少85.43 %。

(4) 根据实验结论分析预测,将两种水辅助条件下的水介质状态由静态改为动态,可以促进制孔过程中碎屑的排出,避免水介质浑浊,进一步提高材料的去除率;在水基辅助条件下,使用更高温度的水介质,实验时更多的水蒸气会参与激光加工过程,从而提高材料去除率。

Influence of different water-assisted methods on femtosecond laser layered-ring trepanning in superalloy

doi: 10.3788/IRLA20220143

- Received Date: 2022-03-03

- Rev Recd Date: 2022-04-17

- Publish Date: 2022-12-22

-

Key words:

- femtosecond laser /

- water assistance /

- laser layered-ring trepanning /

- pulse repetition rate /

- superalloy

Abstract: The effects of water-based and water film assisted methods on the hole quality of femtosecond laser layered-ring trepanning on superalloy was studied. The influence of the laser pulse repetition rate on the hole entrance/exit diameter, taper angle, hole sidewall morphology and hole sidewall roughness under different water assisted methods were compared and analyzed. The results shown that both water-based and water film assistance could improve the quality of femtosecond laser drilling, reduced the hole taper angle and the sidewall roughness, and the improvement effect of water-based assistance was more obvious. When the laser pulse energy was 80 μJ and the pulse repetition rate was 100 kHz, the quality of hole sidewall was better with water-based assistance, and the taper of the hole was reduced by 18.04% compared with that in air. With the increase of laser pulse repetition rate, the hole entrance/exit diameter and taper angle decreased firstly and then increased under the two water-assisted conditions, the changes of hole sidewall roughness were not obvious with water-based assistance, but the hole sidewall roughness with water film assistance increased continuously. The experimental results provided a reference for optimizing the water-assisted femtosecond laser drilling.

DownLoad:

DownLoad: