-

激光通信具有距离远、速率高、体积小、质量轻、功耗低的优点[1-2],所以近年来星间激光通信发展迅速,国内外相关单位已经开展了大量研究工作,研制了实验样机并在卫星上开展了演示实验。单摆镜式粗跟踪伺服转台是一种重要的激光通信机械转台,其采用一面可二维转动的伺服摆镜实现粗跟踪功能,该结构形式具有体积小、质量轻的优势[3]。为了减小摆镜的质量,保证其面形精度,其背部多采用中心支撑方案[4]。王桂冰等人针对空间遥感器摆镜,采用锥形后表面结构结合中心支撑方案,设计的摆镜组件包括摆镜、柔性支撑件以及背部支撑板。采用双层挠性结构在柔性支撑底面开六条相互交错的槽,来吸收温度变化时产生的变形[5]。王朋朋等人针对某型离轴三反光学系统的长条形反射镜采用的中心支撑方式,设计了一种柔性支撑结构,包括锥套、柔性元件、背板、过渡角等,柔性元件采用一种双轴圆弧柔性铰链结构,具有体积小、无机械摩擦、无间隙和高灵敏度传动的特点,可通过自身的变形来改善镜面由于热应力所造成的面形误差[6]。国内的研究均未见对大厚度平背形伺服摆镜支撑方式的相关报道。

针对某激光通信系统地面原理样机,系统采用相干通信体制,为了保证激光偏振态稳定伺服摆镜需镀制介质膜,介质膜厚度和应力较大容易破坏面形精度,为此,伺服摆镜必须采用平背形结构、正面和背部双面同时镀膜的方式保证摆镜正反两面受力对称,减小介质膜对面形精度的影响。由于摆镜的厚度和质量较大,且无法采用中心支撑,对摆镜采用周边支撑方案,对周边支撑的镜座和柔性支撑结构进行了参数化优化设计。系统要求摆镜组件在重力作用以及环境温度(23±5) ℃ 时,组件的一阶谐振频率超过300 Hz;最大面形误差RMS影响成像质量和通信耦合效率,通常要求平面镜RMS≤λ/40。文中通过摆镜形状尺寸优化、支撑方案的设计、柔性支撑结构的参数优化三个方面进行结构设计,并运用有限元方法对组件结构进行仿真分析,最后通过实验验证了组件结构满足设计指标要求。

-

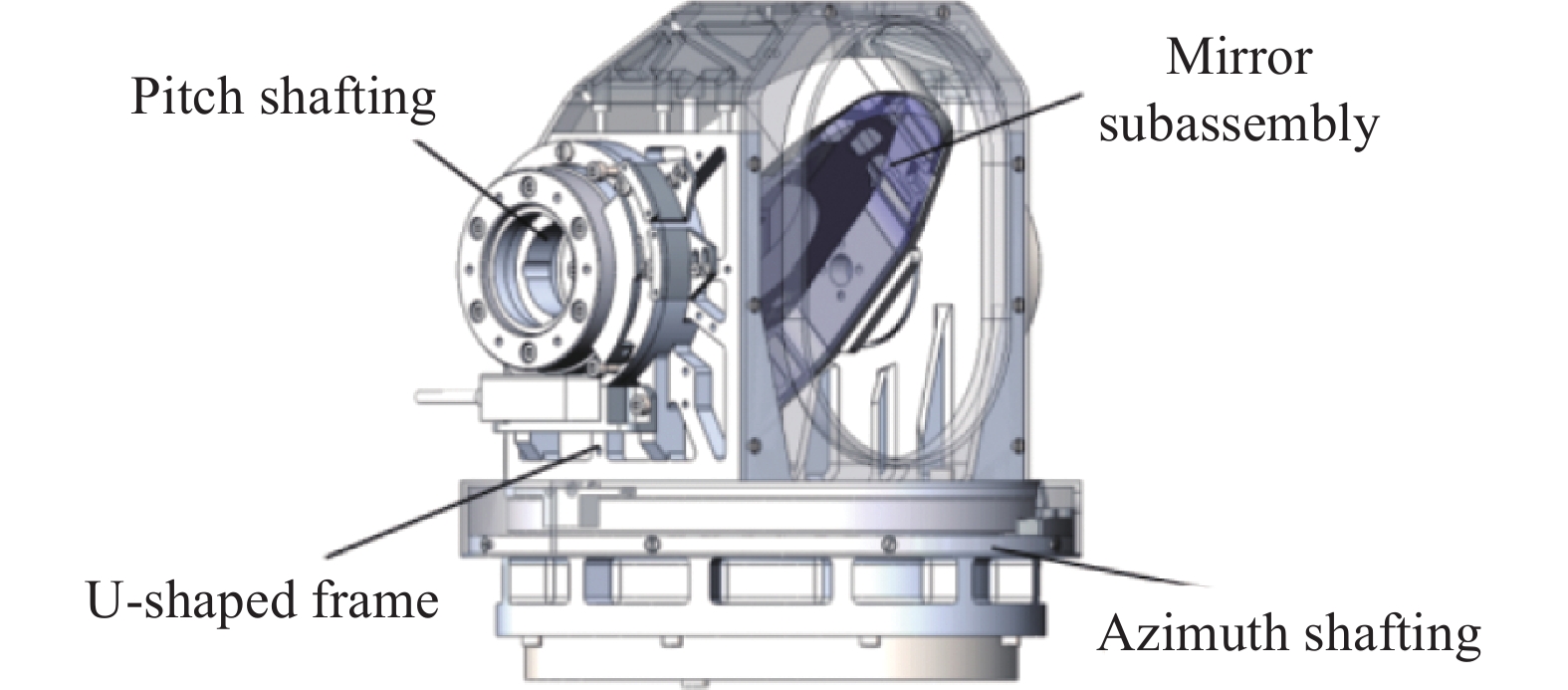

激光通信实现的前提是通信双向链路的建立以及收发视轴保持稳定的精确对准,所以需要良好的光束捕获、对准以及跟踪性能[7]。某星间激光通信系统地面原理样机中,由于需要的工作角度范围不大,为了减小可动部件的质量,降低系统的质量,粗跟踪转台采用单摆镜式结构,总体结构与布局如图1所示。转台主要由方位组件、U形架、俯仰组件和摆镜组件组成,可二维转动摆镜对光轴角度进行调整,实现通信激光的对准捕获和跟踪。

为了保证摆镜结构刚度,减小质量,传统伺服摆镜背部截面多采用非平面结构,常见截面形状有锥形、弯月形、单拱形等。但在文中的激光通信系统中,需要将摆镜正反两面镀制保偏介质膜[8-9],保证镜体等厚,两侧双面受力均匀。系统通过热控设计后,保证摆镜的工作环境温度为±5 ℃。

-

系统有效通光口径为Ф75 mm,摆镜工作角度在60°时长轴最长,留取设计余量后,摆镜有效形状设计为长轴154 mm、短轴79 mm的椭圆,径厚比为8∶1,厚度为20 mm。摆镜材料选用微晶玻璃,加工后面形误差PV优于λ/7,RMS优于λ/50;为减小系统质量,支撑镜座选用钛合金材料,摆镜组件材料性能参数如表1所示。

Part Material E/GPa ρ/g·cm−3 α/℃ k/W∙(M∙K)−3 ν Mirror Zerodur 91 2.53 0.05 1.64 0.24 Support TC4 109 4.44 8.9 7.8 0.31 Table 1. Material properties of reflector components

为了方便在摆镜周围设计粘接点位置,同时为椭圆形摆镜的光学有效区域建立缓冲区,减小粘接点对摆镜面形的影响,故将摆镜设计为八边形结构,每条斜边与椭圆相切,在四条斜边上设计粘接点,每条斜边设计两个粘接点,摆镜平面形状如图2所示。

-

设计时,粘接点处与有效椭圆区域间的镜体可以作为缓冲区,有效减小应力对有效区域内面形的影响。粘接点位置决定了各点应力和缓冲区域的大小,为此有必要对摆镜的形状、切点位置和粘接点位置进行优化。以切点1、粘接点1和粘接点2为例,如图2所示,角度α决定了切点1的位置以及摆镜形状,粘接点与切点的距离L1和L2确定了粘接点位置。由于优化参数较多,采用正交实验法对参数α、L1和L2进行优化[10]。为了简化优化难度,约束条件设定为在重力作用下摆镜椭圆内有效区域面形最优。

结合结构尺寸且保证粘接点位置的合理性,确定α≥108°,L1>22 mm,L2>12 mm,各参数取值如表2所示。采用四水平三因素正交实验法,用16种组合完成全部的64种参数组合的参数优化方案,具体参数设置如表3所示。评价指标为标准地球重力作用下有效椭圆区域内面形精度RMS值,由V表示。

Level Factors α/(°) L1 /mm L2 /mm 1 106 20 14 2 107 21 15 3 108 22 16 4 109 23 17 Table 2. Parameter level table of the position of the bonding point of the pendulum mirror

No. α/(°) L1/mm L2 /mm V/nm 1 106 20 14 0.861 2 106 21 15 0.804 3 106 22 16 0.877 4 106 23 17 1.067 5 107 20 15 0.851 6 107 21 14 0.660 7 107 22 17 1.070 8 107 23 16 0.863 9 108 20 16 0.895 10 108 21 17 0.905 11 108 22 14 1.059 12 108 23 15 1.053 13 109 20 17 1.117 14 109 21 16 1.033 15 109 22 14 1.198 16 109 23 15 1.289 Table 3. Orthogonal test scheme of the position of the bonding point of the pendulum mirror

各因素的极差如表4所示,N1、N2、N3、N4分别表示角度α、粘接点1到切点距离L1、粘接点2到切点的距离L2这三个因素在四个水平条件下摆镜面形RMS值的平均值。R为三个因素全水平平均值中的极差值,极差值越大表示该因素下所选水平对面形精度值的影响越大。

Factors A B C α/(°) L1/mm L2/mm N1 0.902 0.931 0.945 N2 0.861 0.851 0.999 N3 0.978 1.051 0.917 N4 1.159 1.068 1.039 R 0.298 0.217 0.122 Table 4. Range analysis of factors of the position of the bonding point of the pendulum mirror

通过极差分析可得出各因素对摆镜面形的影响顺序依次为:角度α>粘接点2到切点的距离L2>粘接点1到切点距离L1。通过分析,在标准地球重力的工况下最佳组合参数为A2B2C3组合,即α=107°,L1=21 mm,L2=16 mm。

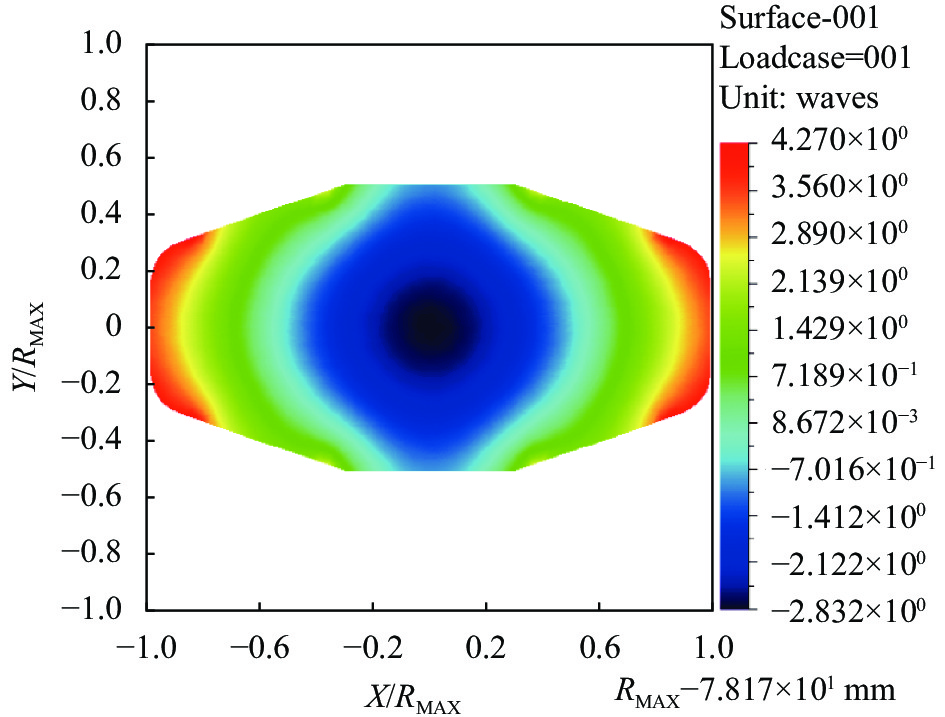

对优化后的摆镜在轴向标准地球重力作用下进行静力学分析。经过Sigfit面形拟合后,摆镜面形精度RMS值为0.784 nm,面形云图如图3所示。

-

常见的摆镜支撑结构有背部支撑、侧面支撑和周边支撑[11-12]三种方式,这三种方式都可以引入柔性结构,降低热应力的影响,但是应用场合有所不同。文中设计的大厚度平背形伺服摆镜,由于镜体背部截面为平背形,镜体等厚且无法采用轻量化设计,常见的背部支撑方案并不适用,故采用周边柔性支撑方案[13]。摆镜组件在设计时不仅要充分保证摆镜面形精度,还要保证组件的谐振频率。因此,需对柔性支撑参数进行优化设计,满足面形和谐振频率的要求。

-

柔性支撑多采用切口铰链结构,通过对粘接点处机械结构进行切口处理形成铰链结构,达到降低结构刚度、减小结构变形产生的应力的作用[14]。

摆镜镜座如图4所示,采用四周封闭的结构形式增大支撑镜座结构的刚度,在摆镜粘接点对应的位置设计柔性铰链和粘接结构[15]。在结构变形时,每个粘接点会在三个方向上产生应力,以粘接点1为例,坐标系X轴垂直于粘接面,Y轴平行于粘接面,Z轴满足右手定则。考虑到摆镜在厚度方向上的变形尺寸远小于另外两个方向,因此忽略Z轴方向的影响,柔性铰链重点考虑X轴和Y轴方向的影响。

Figure 4. Schematic diagram of flexible hinge structure. (a) Schematic diagram of hinge 1; (b) Schematic diagram of hinge 2

为了抑制X轴和Y轴方向应力的影响,每个粘接点的柔性支撑结构由两组铰链构成,通过开槽提高结构柔度,减小结构变形产生的应力,同时使最大应力点远离粘接点,减小对摆镜面形的影响。某一粘接点处柔性铰链1结构如图4(a)所示,铰链1主要抵消X轴方向的应力;柔性铰链2结构如图4(b)所示,铰链2主要抵消Y轴方向应力。镜座在支撑点处设计有注胶点和粘接面,采用硫化硅橡胶粘接,粘接点处设计凸台,方便保证粘接点位置尺寸精度,同时便于柔性铰链的设计与加工。

-

由于摆镜镜座柔性支撑结构参数较多,采用正交实验法对结构参数进行优化。以粘接点1为例,柔性支撑的主要结构参数有:铰链1长度a,铰链1宽度h,铰链1高度b,铰链2长度r,铰链2宽度s,铰链2高度t,各参数如图5所示。

在实际结构设计中,根据结构尺寸以及加工工艺,确定a≤16 mm,h≥2.4 mm,b≥16 mm,r≥2 mm,s≥2.4 mm,t≥8 mm,各参数的取值如表5所示。采用五水平六因素正交实验法,根据L25(56)标准正交表,用25种组合完成全部15625种参数组合的柔性支撑结构的参数优化方案,具体参数设置如表6所示。评价指标为5 ℃温升作用下有效椭圆区域内面形精度RMS值,均由P表示。

Level Factors a/mm h/mm b/mm r/mm s/mm t/mm 1 12 2.4 16.5 2 2.4 8 2 13 2.8 17 2.5 2.8 9 3 14 3.2 17.5 3 3.2 10 4 15 3.6 18 3.5 3.6 11 5 16 4 18.5 4 4 12 Table 5. Parameter level of flexible support structure

No. a/mm h/mm b/mm r/mm s/mm t/mm P/nm 1 12 2.4 16.5 2 2.4 8 24.03 2 12 2.8 17 2.5 2.8 9 33.04 3 12 3.2 17.5 3 3.2 10 44.58 4 12 3.6 18 3.5 3.6 11 59.03 5 12 4 18.5 4 4 12 70.99 6 13 2.4 17 3 3.6 12 41.27 7 13 2.8 17.5 3.5 4 8 38.35 8 13 3.2 18 4 2.4 9 22.70 9 13 3.6 18.5 2 2.8 10 33.63 10 13 4 16.5 2.5 3.2 11 47.07 11 14 2.4 17.5 4 2.8 11 20.58 12 14 2.8 18 2 3.2 12 30.08 13 14 3.2 18.5 2.5 3.6 8 25.17 14 14 3.6 16.5 3 4 9 44.48 15 14 4 17 3.5 2.4 10 24.02 16 15 2.4 18 2.5 4 10 29.49 17 15 2.8 18.5 3 2.4 11 16.25 18 15 3.2 16.5 3.5 2.8 12 22.05 19 15 3.6 17 4 3.2 8 16.60 20 15 4 17.5 2 3.6 9 30.25 21 16 2.4 18.5 4 3.2 9 12.01 22 16 2.8 16.5 2 3.6 10 20.19 23 16 3.2 17 2.5 4 11 32.46 24 16 3.6 17.5 3 2.4 12 14.84 25 16 4 18 3.5 2.8 8 10.09 Table 6. Orthogonal test scheme of flexible support structure

各因素的极差如表7所示,N1、N2、N3、N4、N5分别表示柔性支撑结构铰链1长度a、铰链1宽度h、铰链1高度b、铰链2长度r、铰链2宽度s以及铰链2高度t这六个因素在五个水平条件下摆镜面形RMS值的平均值。R为因素全水平平均值中的极差值,极差值越大表示该因素下所选水平对面形精度值的影响越大。

Factors A B C D E F a/mm h/mm b/mm r/mm s/mm t/mm N1 46.33 25.48 31.64 27.70 20.37 22.85 N2 36.60 27.58 29.48 33.45 23.88 28.57 N3 28.87 29.27 29.72 32.28 30.07 30.38 N4 22.93 33.72 30.28 30.71 35.18 35.08 N5 17.92 36.48 31.61 28.58 43.15 35.85 R 28.41 11 2.16 5.75 22.78 13 Table 7. Range analysis of factors of flexible support structure

通过极差分析可得出各因素对摆镜面形的影响顺序依次为:铰链1长度a>铰链2宽度s>铰链2高度t>铰链1宽度h>铰链2长度r>铰链1高度b。根据四个水平的面形平均值可见,在5 ℃温升工况下最佳组合参数为A5B1C2D1E1F1,即a=16 mm,h=2.4 mm,b=17 mm,r=2 mm,s=2.4 mm,t=8 mm。

-

为了验证摆镜组件的动态刚度,对模型进行模态分析,边界条件定义为摆镜镜座与转台连接位置六自由度全约束,与实际安装工况一致。

摆镜组件的前六阶模态分析结果如表8所示。有限元分析结果表明,摆镜组件一阶频率为446.66 Hz,动态刚度较高,满足设计指标要求的元件模态频率大于300 Hz。一阶阵型为摆镜沿x轴平移,结果云图如图6所示,因此摆镜组件完全满足结构动态刚度要求。

Order Fz/Hz Mode of vibration 1 446.66 Pendulum mirror translates along the x-axis 2 1137.7 Pendulum mirror translates along the y-axis 3 1248.2 Pendulum mirror translates along the z-axis 4 1282.7 Pendulum mirror rotates around x-axis 5 1361.1 Pendulum mirror rotates around z-axis 6 2134.1 Pendulum mirror rotates around y-axis Table 8. Results of modal analysis of pendulum mirror assembly

-

对摆镜组件在X、Y、Z三个方向施加标准地球重力载荷以及5 ℃温升(降)耦合的工况下分析结果如表9所示,面形云图如图7所示。

Load case direction Temperature rise Temperature reduction PV RMS PV RMS X λ/16.34 λ/92.13 λ/16.75 λ/95.13 Y λ/17.23 λ/94.97 λ/17.47 λ/95.43 Z λ/16.55 λ/83.28 λ/19.88 λ/101 Table 9. Analysis results of 5 ℃ temperature rise (fall) and standard earth gravity under the pendulum mirror surface shape accuracy (Unit: nm)

从表9的分析结果可见,摆镜组件在标准地球重力载荷以及5 ℃均匀温升、温降的共同作用下,最大面形误差PV值为λ/16.34,RMS值为λ/83.28。摆镜的最终面形精度由摆镜加工后面形与支撑机构产生的面形误差共同决定。为评价支撑后摆镜面形,整体面形误差PV值按摆镜加工面形误差PV值与支撑结构产生面形误差PV值叠加计算,RMS值按两者的均方根值计算。经计算后,采用该支撑结构后摆镜的最终面形误差PV值为λ/5,RMS值为λ/42.87,满足面形精度要求。

-

摆镜镜座实物如图8(a)所示,摆镜组件实物如图8(b)所示,整机装配图如图8(c)所示。使用ZYGO激光干涉仪在(23±5) ℃温度范围内对摆镜组件进行面形检测,检测系统如图9所示。

检测结果如表10所示,不同温度下摆镜面形结果如图10所示。经检测,摆镜组件在(23±5) ℃温度范围的面形误差RMS值最大为λ/43.28,满足指标要求,证明该周边柔性支撑结构能够保证摆镜组件具有良好的热稳定性。

Temperature/°C PV RMS 15 λ/5.41 λ/45.34 20 λ/5.49 λ/45.71 25 λ/5.10 λ/43.28 Table 10. Results of pendulum mirror assembly face shape test (Unit: nm)

-

通过正弦扫频实验验证摆镜柔性支撑的结构刚度。在摆镜镜面安装传感器,测该点的响应曲线如图11所示。由响应曲线可知,摆镜组件Z向一阶谐振频率为458.3 Hz,与模态分析结果的相对误差为2.5%,分析结果相对准确。

-

为保证大厚度平背形伺服摆镜系统在恶劣环境下的动态刚度以及面形精度,提出了一种周边柔性支撑结构方案。对摆镜形状、粘接点位置以及周边柔性支撑结构进行了参数化设计,并根据正交实验法对其参数进行优化,得到了满足设计要求的周边柔性支撑结构。经过有限元分析,摆镜组件基频为446.66 Hz,满足设计指标要求的元件模态频率大于300 Hz;在(23±5) ℃温度范围内,摆镜面形PV值为λ/5,RMS值为λ/42.87,优于λ/40的指标要求。使用ZYGO激光干涉仪对摆镜在不同温度下进行面形检测,实验结果表明,摆镜面形RMS值优于λ/40的设计值。因此,对摆镜形状、粘接点位置以及周边柔性支撑结构的参数化设计使摆镜组件的结构刚度和热稳定性满足了系统的设计要求。

Laser communication flat back servo pendulum mirror support structure optimization design

doi: 10.3788/IRLA20230336

- Received Date: 2023-06-07

- Rev Recd Date: 2023-07-04

- Available Online: 2023-12-22

- Publish Date: 2023-12-22

-

Key words:

- laser communication /

- flexible support /

- orthogonal optimization /

- peripheral support /

- pendulum mirror

Abstract:

DownLoad:

DownLoad: