-

飞秒激光加工具有烧蚀阈值低、加工精度高等特点[1]。飞秒激光烧蚀阈值受辐照的脉冲数影响,研究单脉冲以及多脉冲作用下飞秒激光烧蚀阈值和孵化效应对于可控、精确的激光加工具有十分重要的意义[2]。近年来,人们针对飞秒激光与材料的相互作用及其应用、飞秒激光烧蚀及孵化效应等已开展了广泛研究。飞秒激光作用于透明电介质材料时,通过多光子吸收、隧穿电离、碰撞电离等过程将电子从价带激发到导带,产生局域化的自由等离子体。充分电离时,逆轫致辐射产生电子和离子间的碰撞,等离子体中的电子通过逆轫致辐射吸收激光能量后,电子将会被加热到极高的温度,随后电子再通过电子声子耦合将能量传递给晶格,从而使等离子体温度升高[3−6]。在多激光脉冲重复作用过程中,激光诱导形成的缺陷(如色心等)逐步积累,材料的光学特性逐渐发生改变,发生孵化效应,烧蚀阈值降低[5,7−8]。孵化效应已经在多种材料中被观察到:德国马克斯-伯恩非线性光学和短脉冲光谱学研究所的Ashkenasi等人发现钇锂氟化物(YLF)和熔石英的表面烧蚀阈值在第一次激光脉冲辐照后会发生急剧下降[2,5];日本中部大学的Qi等人发现孵化效应导致蓝宝石的烧蚀阈值与辐照在衬底表面的激光脉冲数成反比[9];上海交通大学的Chen等人发现在铌酸锂晶体中,多脉冲烧蚀阈值相较单脉冲烧蚀阈值发生了明显的降低[10]。利用孵化效应,可以有效降低脆性电介质的烧蚀阈值,获得更小的飞秒激光微加工特征尺寸和比聚焦激光束直径小的微孔[2]。 上海工程技术大学的赵万芹等人论述了超短脉冲激光与不同类型材料之间的相互作用机制,并总结和对比了孔径和阈值关系模型、多脉冲累积模型和单脉冲烧蚀深度三个经典模型[11−12]。四川大学的王震等人利用双温方程推导了多脉冲辐照分析模型,分别对单脉冲及多脉冲烧蚀铁的温度变化规律进行了定量计算和比较,为加工过程中的激光控制提供了理论依据[13];宁波大学的周伟杰等人研究了拥有超20 μm的超宽透射范围的硫族化物玻璃(GAST)的激光诱导损伤阈值(LIDT),其随着样品中Ge含量的增加而增加,随着激光的脉冲辐照数量和重复率的增加而逐渐减小[14]。

YAG晶体在0.25~5 μm范围内具有较高的透过率,是一种优良的紫外、红外光学材料,且具有优良的热力学性质[15]、良好的抗温度蠕变性[16],以及很强的耐高温塑性变形能力[17]。YAG的力学性能和化学稳定性接近蓝宝石晶体,并且没有蓝宝石的双折射效应[18]。YAG在飞秒激光作用下的损伤机理、烧蚀特性以及孵化效应具有十分重要的理论意义和应用价值[19],尚需进一步研究。文中旨在研究多脉冲作用下YAG晶体烧蚀过程中的孵化效应,对比分析典型孵化模型的优缺点和适用性,获得单脉冲、多脉冲作用下YAG的烧蚀阈值,为超快飞秒激光处理和加工YAG提供实验参数参考。

-

飞秒激光的空间分布近似为高斯光束,其空间能流密度分布可由下式给出[20]:

式中:r表示到光束中心的距离;$ \mathrm{\omega } $为高斯光束的光斑半径;$ {{F}}_{0} $表示高斯光束中心的激光能流密度(高斯光束截面上的最大激光能流密度)。$ {{F}}_{0} $与入射脉冲能量$ {{E}}_{\mathrm{i}\mathrm{n}} $相关[10,20]:

其中,$ {{E}}_{\mathrm{i}\mathrm{n}} $可简单地由平均激光功率$ {{P}}_{\mathrm{a}\mathrm{v}\mathrm{g}} $和激光的重复率 f 得到:

在脉冲数一定的情况下,损伤坑的尺寸随脉冲能量的增加而增加。N个激光脉冲作用后的阈值能量$ {{E}}_{\mathrm{t}\mathrm{h}} $(N)与损伤坑直径的平方$ {{D}}^{2} $相关[5,10,20−21]:

当$ {D}^{2} $=0时,所得的${E}_{{\rm{th}}}$(N)即为作用脉冲数N时的阈值能量。相应的,可以求得阈值激光能流密度${F}_{{\rm{th}}}$。由公式(4),可以通过绘制D2–ln${E}_{{\rm{in}}}$曲线来计算${E}_{{\rm{th}}}$(N)和$ \mathrm{\omega } $。

在多脉冲作用下,由于非线性吸收和材料缺陷的积累,材料烧蚀过程中将发生孵化现象。

-

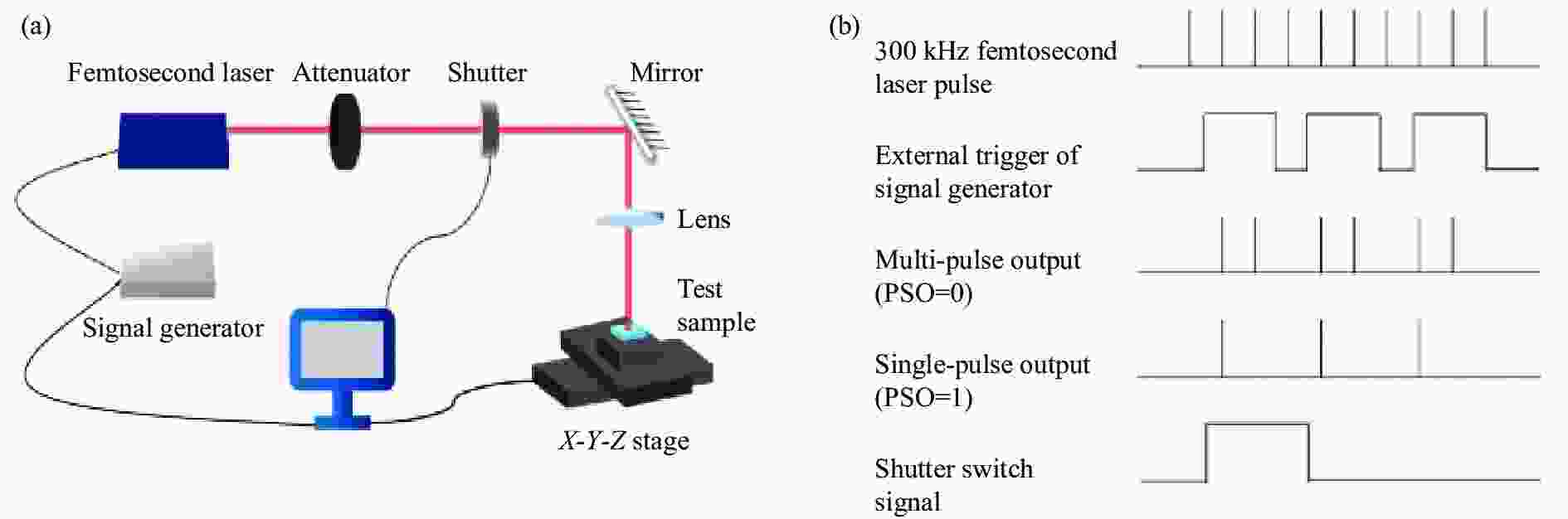

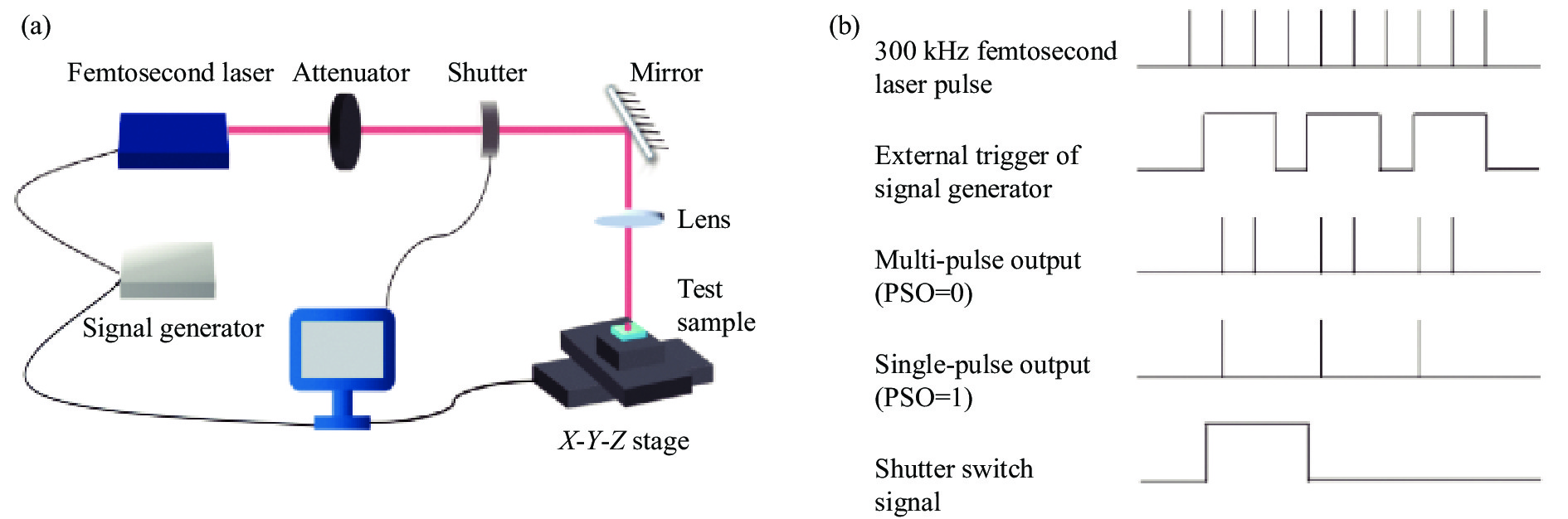

实验装置示意图如图1(a)所示,飞秒激光输出模式通过信号发生器外触发控制,高精度电子快门用于控制作用于样品表面的脉冲数量,半波片和偏振器的组合(衰减器)实现激光功率的调控,反射镜用于对光束转向,使其正入射于样品表面。

Figure 1. Experimental schematic diagram. (a) Schematic diagram of the experimental device; (b) Timing diagram of femtosecond laser output pulse number control

实验中,飞秒激光采用外控模式,其控制时序如图1(b)所示,通过同步位置输出模式(PSO=1)控制单脉冲输出,在高精度函数/任意波形信号发生器(DG1000Z)的一次高电平期间输出一个激光脉冲;通过电平触发输出模式(PSO=0)实现多脉冲输出,在信号发生器的高电平期间,激光脉冲连续输出。设置信号发生器的触发频率至百赫兹以下,此时电子快门的开关精度足够实现快门打开时间刚好为一个信号发生器外触发周期,从而实现对脉冲数量的精确控制。

-

实验采用YAG晶体,样品尺寸为5 mm×3 mm×0.5 mm。实验前,使用丙酮对YAG进行浸泡清洗,去除表面杂质和灰尘。采用中心波长为1030 nm的光纤飞秒激光器,脉宽约为400 fs,重复频率为300 kHz。利用10×显微物镜(NA = 0.28)将激光束聚焦于样品表面,光斑大小为$ {\mathrm{\omega }}_{0} $=(3.5±0.2) μm。样品的移动通过高精度三维电控位移台实现。

样品固定于高精度三维电控位移台上,表面形貌变化及损伤过程可以利用CCD相机在线观察。在每个加工的点阵中,每一行弹坑都用相同的脉冲数N和固定的单脉冲能量值EP进行烧蚀。在相同的实验参数条件下,对YAG晶体样品表面的不同位置进行辐照,所有实验均在常温、常压的空气中进行。YAG晶体经过激光辐照后,采用光学显微镜(KEYENCE VH-Z500) 、扫描电子显微镜(SU8220)和原子力显微镜(Dimension ICON)观察样品的烧蚀形貌,并测量不同烧蚀坑的直径。

-

单脉冲作用后的烧蚀形貌如图2(a)所示。在单脉冲烧蚀下,损伤坑的直径随着脉冲能量的增加而增加。图2(b)所示为D2(损伤坑直径的平方)与EP的半对数图的相对线性拟合,$ {{F}}_{\mathrm{t}\mathrm{h}} $可以通过线性外推到D2 =0获取。实验测得单脉冲下的烧蚀阈值为(11.77±1.81) J/cm2。图2(c)所示为YAG晶体的单脉冲作用SEM图,可以看出,在飞秒激光作用后,烧蚀坑内和周围形成了一定数量的纳米颗粒。图2(d)所示为单脉冲下烧蚀坑的AFM测量结果,在图中所示能量范围的单脉冲飞秒激光作用后,烧蚀坑直径约为1.5~3 μm,烧蚀深度约为170~290 nm。

-

多脉冲作用下,孵化效应在烧蚀过程中扮演重要角色。在介电材料和半导体材料中,由外部激光作用引起的晶格缺陷,可以在带隙中产生额外的能级。新的激发路径的存在有利于对后续激光脉冲能量的吸收[5]。缺陷密度随着激光辐照脉冲数的增加而增加,直到达到饱和[22]。同时,缺陷的积累将导致有效吸收系数增加[23],表面烧蚀阈值随之降低,直到达到饱和。

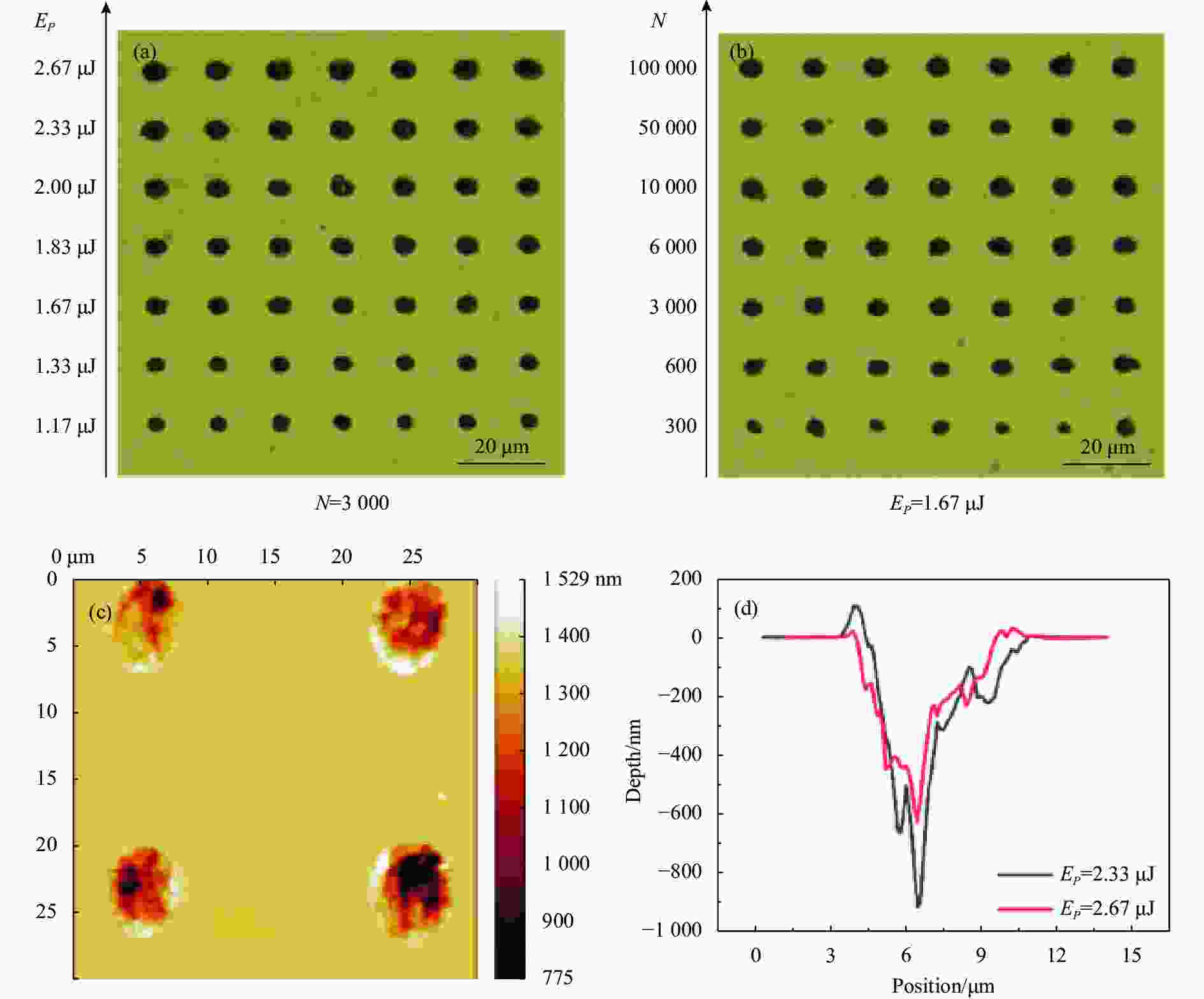

图3(a)为激光重频300 kHz、脉冲数量N=3 000时,不同烧蚀能量下的烧蚀坑形貌。随着激光功率的增加,烧蚀坑直径随之增加,且同一功率下的烧蚀坑直径大小基本相当。图3(b)为脉冲能量为1.67 μJ时,不同脉冲数飞秒激光作用后的烧蚀坑形貌。可见在脉冲数较少时,烧蚀坑的直径更小。随着作用脉冲数的增加,烧蚀坑的直径也随之增加。当脉冲数超过600后,作用材料的脉冲数增加对直径大小的增加效果显著降低。实验中观察到作用脉冲数较少时,相同实验参数的多组重复实验中烧蚀坑的大小之间的差异比多脉冲作用下大,这是由于相对于作用脉冲数较多的情况,作用脉冲数较少时烧蚀坑的大小、形貌受前期的激光脉冲作用产生的已形成的表面局部形貌影响更大。材料的去除主要是由于热气化和库伦爆炸,纳米颗粒将再沉积于烧蚀坑内或周围。单脉冲作用后的纳米颗粒沉积如图2(c)所示,这些纳米颗粒将导致后续激光脉冲作用时的能量沉积受到调制[24]。由于纳米颗粒的具体位置具有一定随机性,将导致在作用脉冲数较少时,烧蚀坑大小形状具有一定差异;当脉冲数较多时,烧蚀坑的大小仅受阈值影响。

Figure 3. (a) Optical micrographs (1000×) of YAG crystals after ablation with different pulse energies, with pulse number N=3 000; (b) Optical micrographs (1000×) of YAG crystals ablated with different pulse numbers, with pulse energy EP 1.67=μJ; (c) AFM ablation morphology of YAG crystals under multi-pulse action; (d) Cross section diagram of ablation craters under multi-pulses

由图3(c)和图3(d)可得,多脉冲作用下,YAG的烧蚀形貌极不规则,烧蚀直径为7~8 μm,烧蚀深度为600~900 nm。在同样的激光能量下,单脉冲作用后的烧蚀坑深度较浅,直径较小,而多脉冲作用后的烧蚀坑边缘出现了不规则的凸起(烧蚀产生的纳米颗粒堆积),烧蚀坑内壁变得更为粗糙。根据AFM测量所得的YAG晶体单脉冲烧蚀坑直径,求得其单脉冲烧蚀阈值为$ {{F}}_{\mathrm{t}\mathrm{h},1} $=(12.16±2.43) J/cm2,该值与光学显微镜下的结果基本一致。

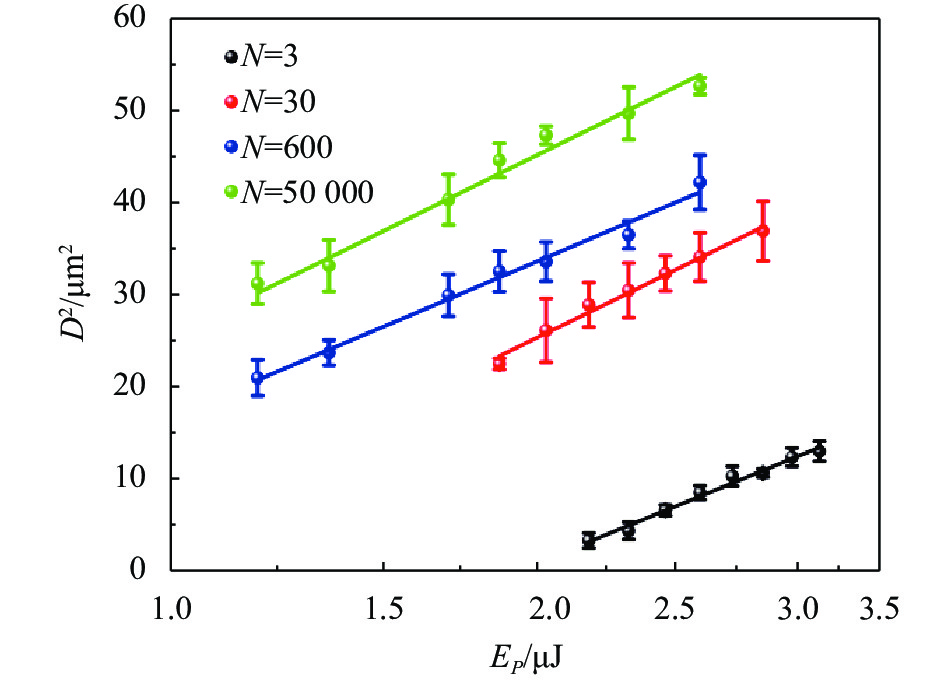

随着脉冲能量和脉冲数量的增加,烧蚀孔直径随之增加,烧蚀阈值明显降低。图4所示为多脉冲烧蚀的D2与EP半对数图。图中,黑色拟合曲线(N=3)和红色拟合曲线(N=30)的相对间距较大,而蓝色曲线(N=600)与绿色曲线(N=50 000)的相对间距明显变小,表明在脉冲数较少的情况下,烧蚀阈值急剧降低。随着脉冲数的增加,拟合曲线间的相对距离增加速度变缓,即烧蚀阈值的降低速度急剧变缓。当脉冲数足够多时,拟合曲线将逐渐趋于重合,此时孵化饱和发生。曲线的斜率对应飞秒激光作用在材料表面的光斑面积,通过对拟合曲线斜率的计算,可以得到作用于材料表面处的光斑大小[25]。四条拟合曲线斜率基本一致,即激光光斑大小在样品表面处基本相同。

-

研究者们相继建立了三种孵化模型来描述多脉冲作用下材料的烧蚀规律,被广泛用于各种介电材料和半导体材料[5,17,26]孵化效应的研究。文中分别采用上述三种模型,对单脉冲和多脉冲飞秒激光烧蚀下的孵化效应进行分析。

模型Ⅰ:Jee等人引入孵化系数S,将多脉冲阈值能流密度$ {{F}}_{\mathrm{t}\mathrm{h}} $(N)和单脉冲阈值能流密度$ {{F}}_{\mathrm{t}\mathrm{h},1} $通过幂函数[27]进行了描述,如下式所示:

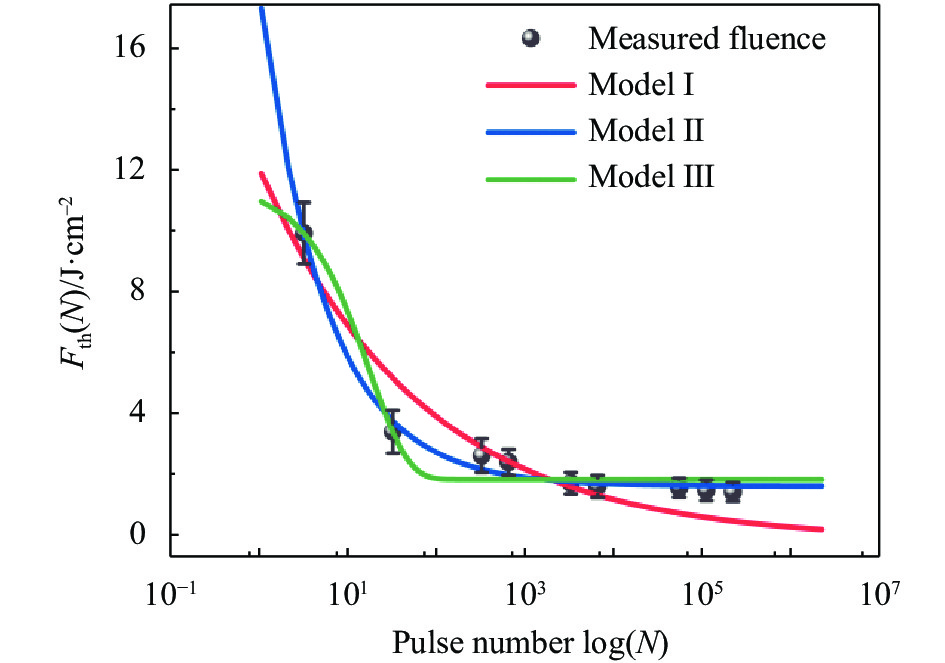

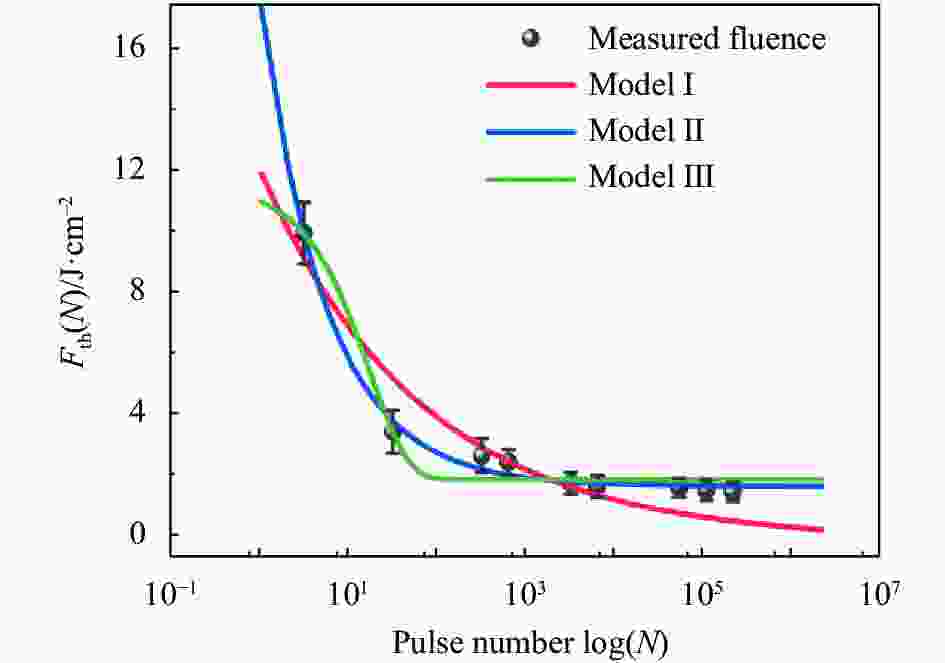

通过模型Ⅰ拟合得到$ {{F}}_{\mathrm{t}\mathrm{h},1} $=(12.27±3.56) J/cm2,与AFM及光学显微镜的测量结果较为接近,而在多脉冲下的拟合结果误差较大。模型Ⅰ(图5中红色曲线)能较为准确地拟合少脉冲数下的烧蚀阈值。在脉冲数很少时,烧蚀坑大小具有不稳定性,烧蚀阈值的测量结果误差增加,而通过模型Ⅰ可以一定程度上解决这一困难。

Figure 5. Experimental and fitting results of ablation threshold energy flux density (black sphere) $ {{F}}_{\rm{t}\rm{h}} $(N) as a semi logarithmic function of laser pulse number N under the shot of multi pulse femtosecond laser (The red curve (Model I), blue curve (Model II), and green curve (Model III) correspond to the linear fitting of the three models, respectively)

模型Ⅱ:在模型Ⅰ的基础上,Di Niso等人引入了偏置值${{F}}_{\mathrm{t}\mathrm{h},\mathrm{\infty }}$(孵化饱和阈值能流密度[28])对模型进行优化,用于描述孵化饱和的现象,如下式所示:

模型Ⅱ的拟合结果如图5中蓝色曲线所示,其具有很高的拟合度和相关系数。通过模型所得的${{F}}_{\mathrm{t}\mathrm{h},\mathrm{\infty }}=(1.82\pm$0.37) J/cm2与实验观察的结果最为吻合。相比模型Ⅰ,在脉冲数量较多时,模型Ⅱ对孵化饱和现象具有很好的拟合结果,较好地描述了实验中随着脉冲数量增多、烧蚀阈值降低的趋势逐渐减缓、直到相对稳定的现象。但当作用脉冲数小于10时,模型Ⅱ过高地估计了此时的烧蚀阈值。

孵化系数S为取决于目标材料的经验系数,孵化系数能够很好地反映飞秒激光多脉冲烧蚀过程中的孵化效应强度。模型Ⅰ和模型Ⅱ的S取值在0~1之间。模型Ⅰ中,S越小,材料的孵化效应越强,烧蚀阈值随辐照脉冲数下降越快。S趋于1时,烧蚀阈值随脉冲数的增加降低变慢,此时的孵化效应逐渐变弱。S=1时,不存在孵化效应,此时材料的烧蚀阈值与脉冲数无关。模型Ⅰ最初主要应用于金属的孵化效应解释,由于未考虑孵化效应饱和的情况,拟合结果为理想情况下的孵化效应,即随着脉冲数的增加,多脉冲烧蚀阈值持续降低,直到在无限脉冲数下降到0,因此该模型具有一定的局限性。在模型Ⅰ的基础上提出的模型Ⅱ考虑了近似在无限脉冲数下的饱和现象,引入一个恒定的饱和阈值量,更好地解释了孵化现象。模型Ⅱ的孵化系数(S=0.42±0.17) 相较于模型Ⅰ(0.76±0.08)明显降低,这是由于在实际情况下,孵化效应会发生饱和,饱和孵化阈值的引入必然导致观察到的孵化效应增强,S随之降低。

模型Ⅲ:类似于模型Ⅱ,Rosenfeld等人也考虑了偏置值(孵化饱和阈值能流密度)$ {{F}}_{\mathrm{t}\mathrm{h},\mathrm{\infty }} $,建立了指数函数孵化模型[2]来描述多脉冲下的孵化饱和现象,如下式所示:

不同于模型Ⅰ和模型Ⅱ,模型Ⅲ使用因子k表示指数模型的孵化系数。指数孵化模型的整体(单脉冲和多脉冲)衰减过程与实验吻合的整体趋势最为相近。从与实验结果的误差大小来看,模型Ⅲ(图5中绿色曲线)在整体上能够较好地拟合不同脉冲数下的烧蚀阈值,但在单脉冲和多脉冲下的拟合效果分别差于模型Ⅰ和模型Ⅱ。

模型Ⅲ的因子k也为取决于目标材料的经验系数,但根据材料的孵化强度,k的值理论上可以取任何正值。在透明材料中,孵化系数一般在0.06左右,k对应孵化强度,表示单位脉冲数作用后烧蚀阈值的改变度。k值越大,材料的孵化效应越强,烧蚀阈值随脉冲数的增加下降得越快,孵化饱和的发生所需的脉冲数越少。在烧蚀阈值降低到一定值后,继续增加作用脉冲数,烧蚀阈值的改变量将越来越小,与该模型的结果一致。模型Ⅲ已广泛用于电介质材料孵化效应的解释,如石英、蓝宝石、氟化钙和氮化镓等,并具有最佳的整体拟合度。

表1总结了的三种不同孵化模型的拟合参数,其中R2表示模型的拟合函数和实验数据的相关系数。显然,在不考虑脉冲数较少的情况下,模型Ⅱ具有最高的拟合相关系数;而当考虑脉冲数较少的拟合时,模型Ⅲ则为相关系数最高且适用的模型。

Parameter Model Ⅰ Model Ⅱ Model Ⅲ Fth,1/J·cm–2 12.27±3.56 17.79±3.63 11.34±0.83 Fth,∞/J·cm–2 - 1.82±0.37 2.04±0.18 S 0.76±0.08 0.42±0.17 - k - - 0.061±0.012 R2 0.891 0.990 0.977 Table 1. Figure 5 fits the results

不同的模型具有不同的适用性,在不同的条件下,可采用不同的模型来描述材料在不同脉冲数作用下的烧蚀过程。文中拟合得到的模型Ⅰ的孵化系数S、模型Ⅲ的孵化系数k与文献报道的其他透明材料(如石英[5]和蓝宝石[2])相当,所得孵化模型结果也与文献中基本一致。模型Ⅱ的孵化系数较文献中其他材料大了约一倍,但相关系数明显更高,对多脉冲(脉冲数大于10)下YAG晶体的孵化效应拟合较好。文中研究获得了波长为1030 nm、脉宽为400 fs的飞秒激光作用下YAG晶体烧蚀阈值。针对YAG晶体烧蚀过程,对比了三种常用的孵化模型对不同脉冲数作用下烧蚀阈值的拟合效果。研究发现,三种模型对不同脉冲数下的烧蚀阈值具有不同的拟合准确度,通过三种模型可以一定程度上得到所有脉冲数作用下的较为准确的烧蚀阈值,对飞秒激光加工过程中的参数控制具有重要意义。电子科技大学的Xu等人[29]报道的YAG晶体在800 nm飞秒激光(脉宽479 fs)辐照下的烧蚀阈值为5.04 J/cm2,约为文中的1/2。YAG晶体是宽带隙材料,通过多光子吸收过程吸收激光能量,在这个过程中,吸收的光子阶数越高,吸收系数则越小[30]。1030 nm激光的光子能量低于800 nm激光的光子能量,需要更高阶多光子吸收才能有效实现激光能量的有效吸收。因此,1030 nm飞秒激光作用下的烧蚀阈值相较于800 nm大幅上升。

-

文中研究了1030 nm飞秒激光作用YAG晶体的烧蚀阈值和孵化效应,并通过实验获得了单脉冲烧蚀阈值。研究了多脉冲下烧蚀阈值的变化规律,结合三种孵化模型,研究了多脉冲下的孵化现象。其中,模型Ⅰ适用于单脉冲烧蚀阈值拟合;模型Ⅱ在多脉冲下具有最佳的拟合准确性;模型Ⅲ具有最佳的整体拟合性。该研究提供了超快飞秒激光处理和加工YAG的参数及操作条件,为更小结构的表面微结构加工以及参数控制提供了参考。

Threshold and incubation effect of femtosecond laser ablation of YAG crystals

doi: 10.3788/IRLA20230583

- Received Date: 2023-12-08

- Rev Recd Date: 2024-01-26

- Publish Date: 2024-03-21

-

Key words:

- femtosecond laser /

- ablation threshold /

- incubation effect /

- incubation model

Abstract:

DownLoad:

DownLoad: