-

在工业、医疗、国防等领域有着广泛应用的激光二极管(LD)端面泵浦Yb:YAG激光器,因其有着峰值功率高、寿命长等特点,成为了激光技术研究者们的关注对象[1−3]。与Nd:YAG晶体相比,Yb:YAG晶体在高掺杂情况下不会发生浓度猝灭现象,而且量子亏损很小,更容易产生高效高峰值功率的脉冲激光[4]。然而,激光二极管泵浦Yb:YAG晶体在产生激光辐射的同时也会产生大量的热。热的沉积会导致晶体内温度分布不均匀,使激光晶体产生热效应,严重影响了激光的输出功率及光束质量,减小热效应已经成为激光器设计中的关键步骤[5−7]。

以往的热效应研究常采用解析法计算端面绝热晶体热模型的温度场分布[8−10]。然而,这种模型忽略了空气与端面的热交换,分析结果存在一定误差。文中建立了晶体周边恒温冷却、通光面与空气热交换的热模型,采用有限元分析法,对LD端面泵浦的Yb:YAG方形晶体晶体内的温度场、应力场、形变场及热焦距进行了计算,并对不同高斯阶次、光斑半径和泵浦功率下的晶体温度场分布变化进行了定量分析。

-

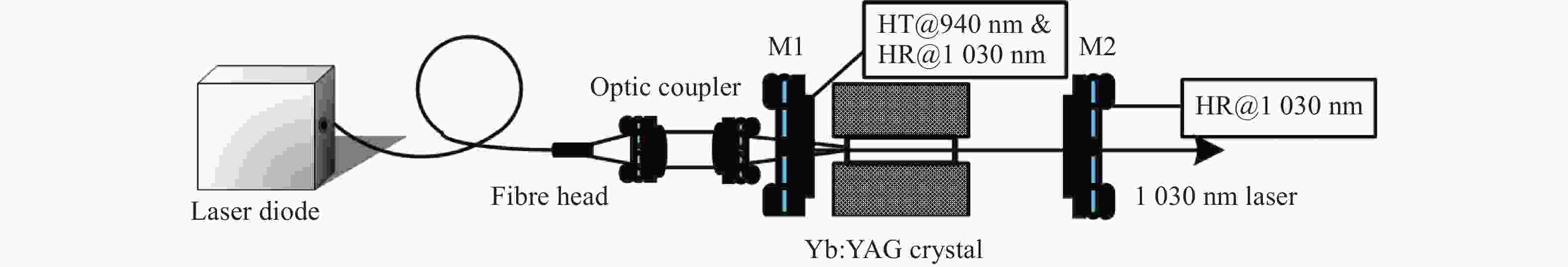

LD发出的泵浦光经耦合镜聚焦后射入激光晶体端面中心。图1为LD端面泵浦Yb:YAG晶体激光器实验装置简图,图2为LD端面泵浦Yb:YAG晶体几何结构图。其中,晶体尺寸为a×b×c,晶体的通关面记作z=0、z=c,令泵浦光线从z=0的端面射入。在晶体端面镀有940 nm波长的增透膜(透射率大于99.8%)和1030 nm波长的增透膜(透射率大于99%)。作为谐振腔输入镜M1,镀有940 nm波长的增透膜(透射率大于99.8%),同时镀有1030 nm波长的高反膜(反射率大于98%);作为谐振腔输出镜M2,镀有1030 nm波长的高反膜(反射率为91%,透射率为9%)。此外,Yb:YAG晶体应涂有导热硅脂并被铟膜包裹,也要尽可能完全接触热沉,达到快速传热冷却的目的。

泵浦光入射到单个光纤中时,其光纤出射光的功率分布为高斯分布,而激光器中由一捆光纤发射到光学耦合元件上的光可视为高斯光的叠加,其光强分布呈“大礼帽”状,称为超高斯分布[11],光强表达式为:

式中:I0为泵浦功率;ω0为泵浦光高斯半径;k为高斯阶次;β为激光介质对泵浦光的吸收系数。

晶体内部的荧光量子效应和内损耗对泵浦光的消耗远大于其他因素造成的光损耗,因此仅考虑量子效应和内损耗所带来的热效应。则z轴截面的热功率密度为:

式中:η为热转换系数,其数值由量子效应及内损耗决定。有:

式中:λp为泵浦光波长,940 nm;λL为出射激光波长,1030 nm。

激光器工作一段时间后,其工作状态和热力学状态达到稳定,此时激光器输出功率稳定,Yb:YAG晶体内部温度场呈梯度分布。方形晶体Yb:YAG的热传导方程可以表示为:

式中:T为温度函数;λ为晶体导热系数。

涂有导热硅脂并被铟膜包裹的晶体与冷却铜块紧密接触,晶体侧面受到铜块限制,仅有与空气接触的端面可自由形变,该情况下z轴方向的应力起到引起形变的主导作用,故将晶体视为各向同性的线弹性材料。

-

通常激光器稳定工作过程中会使用循环水冷,减小热能对激光工作的影响,因此初始温度设为冷却水温度:

考虑到晶体周边恒温冷却、端面与空气热交换,提出以下边界条件。公式(6)描述的是周边恒温冷却条件,x=−a/2、x=a/2、y=−b/2、y=b/2,这四个面始终为冷却水温度。公式(7)、公式(8)为第三类边界条件,z=0、z=c,两个与空气相接触的端面始终与空气热交换。

式中:h为空气传热系数。

此外,激光器水冷装置中的铜块与涂有导热硅脂并被铟膜包裹的晶体紧密接触,故将晶体侧面视为受到铜块限制的固定约束;而端面不受约束,仅与空气接触,故视为可自由形变的端面。

-

按照上述理论建立热模型,该模型尺寸为3 mm×3 mm×4 mm,掺杂浓度为5.0 at.%,对于940 nm泵浦光的吸收系数为5.6 cm−1[11−13],导热系数为0.13 W·cm−1·K−1,高斯阶次为1,冷却温度T0为291 K,热膨胀系数为7.8×10−6 K−1。

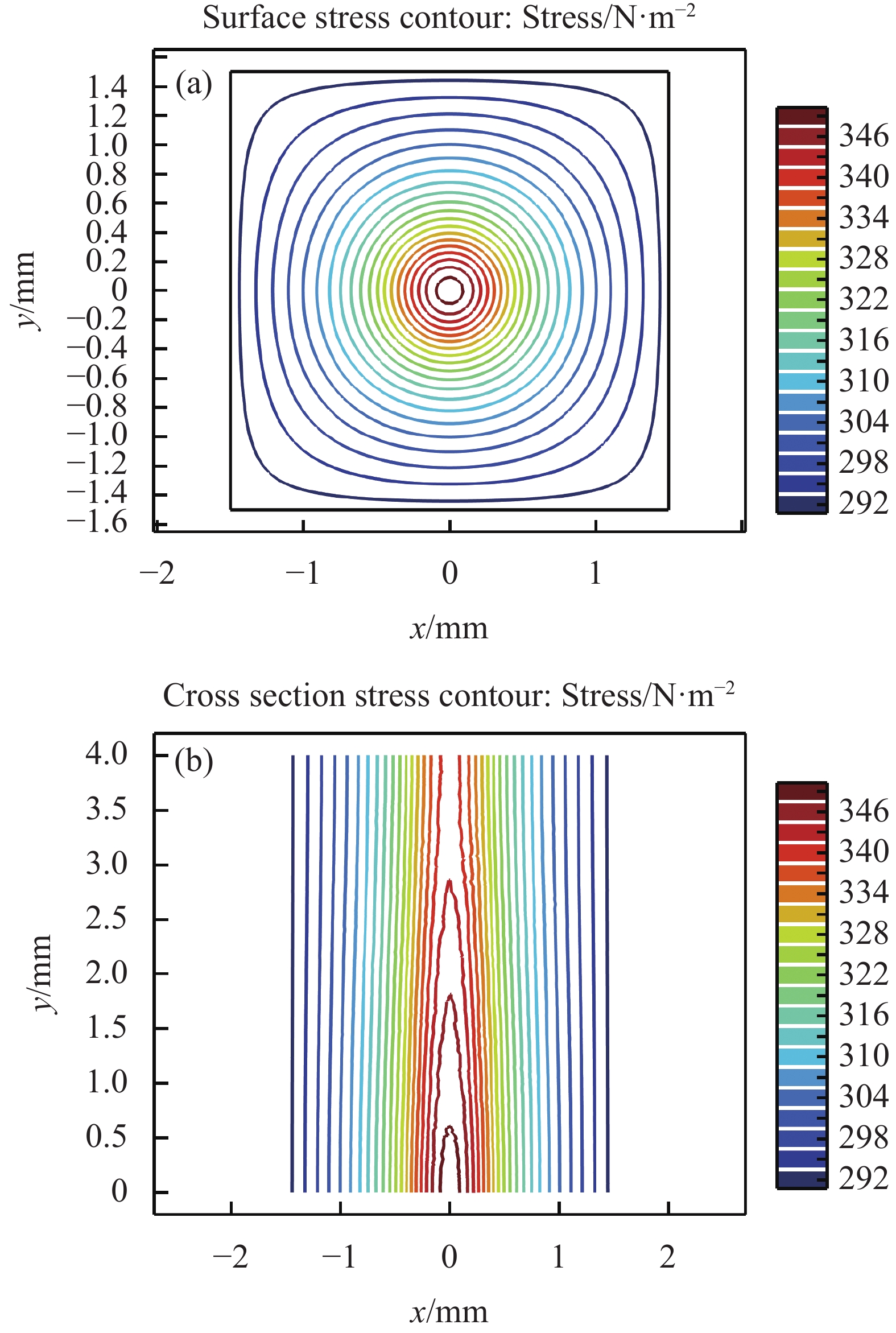

当激光泵浦功率为50 W、泵浦面光斑半径为400 μm时,系统泵浦端面最高温升为59.2 K。图3为激光二极管端面泵浦的Yb:YAG晶体温度场分布图,图4为激光二极管端面泵浦的Yb:YAG晶体内部等温线分布图。

-

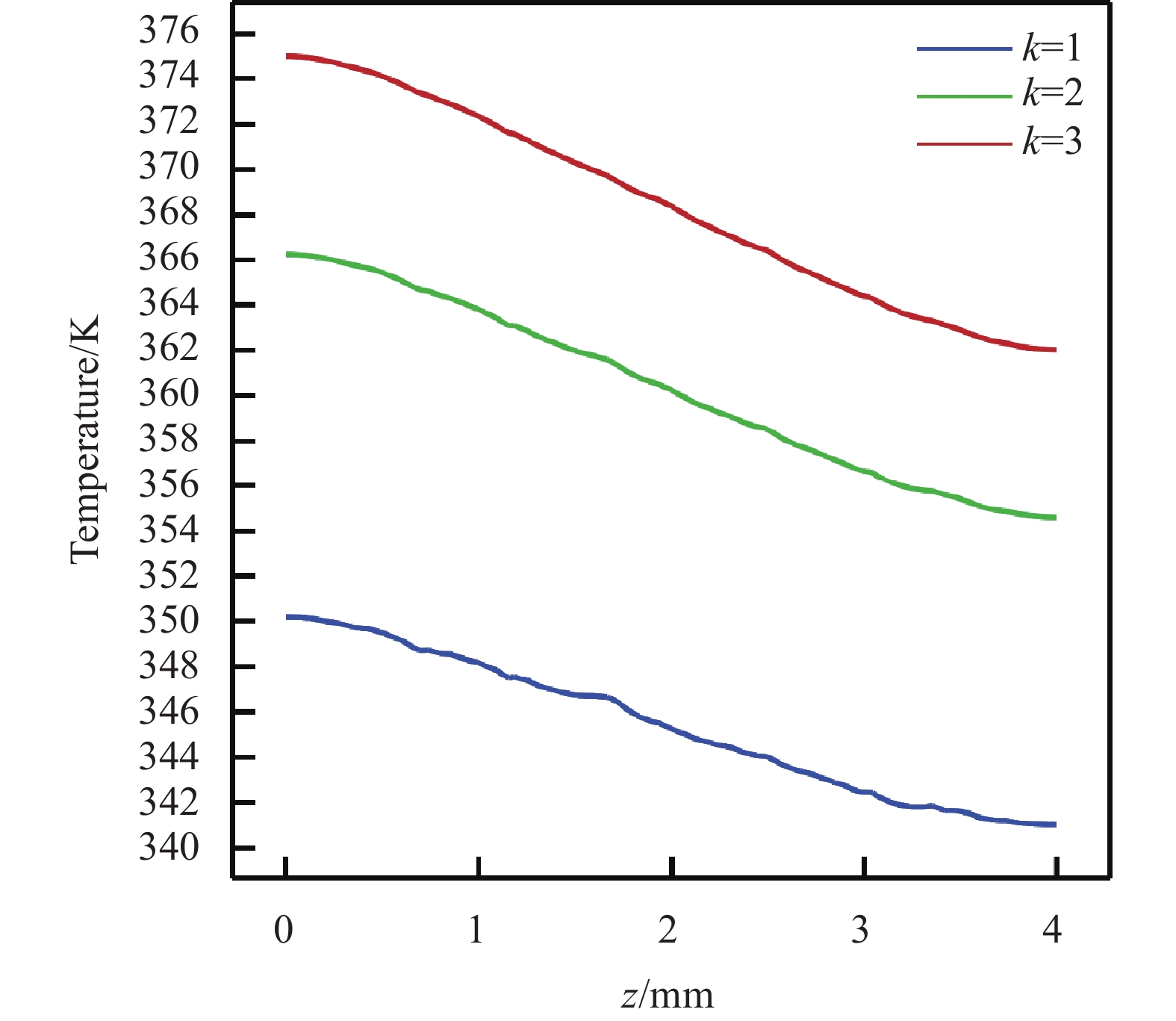

考虑到可以通过改变光纤疏密来调制光斑分布函数,期望通过对比不同高斯阶次的功率函数对激光晶体温度场的影响,获取更为合适的功率函数,对激光器设计提供依据。在其他条件与图3一致的情况下,高斯阶次分别选择1、2、3,其对应的泵浦端面最高温升分别为59.18、75.24、83.99 K。图5为不同高斯阶次下Yb:YAG晶体z轴上的温度场分布对比图,随着高斯阶次提升,温升也在提高,这是因为高斯阶次的提升会使光能的分布更加集中。

-

泵浦光与激光晶体内振荡模的匹配是提高Yb:YAG激光器输出光束质量的关键[14]。在其他条件与图3一致的情况下,只改变泵浦光斑半径,分别为300、350、400、450、500 μm时,其对应的泵浦端面最高温升为105.21、77.30、59.18、46.76、37.88 K。图6为不同光斑半径的Yb:YAG晶体z轴上的温度场分布对比图,可以看出,光斑半径越小,温升越大,这是因为光斑半径越小,其功率密度越大。

-

在符合实验要求的前提下选择适当的泵浦功率,能有效降低温度场的温度。在其他条件与图3一致的情况下,只改变泵浦功率,分别为50、60、70 W,其对应的最高温升为59.18、71.02、82.85 K。图7为不同泵浦功率下的Yb:YAG晶体z轴上的温度场分布对比图,可以看出,功率越大,温升越大。

-

产生激光晶体热透镜效应的原因主要是大量的泵浦能量以热的形式沉积在激光晶体中,而晶体在工作状态下产生热量的主要原因有:能级间非辐射跃迁所释放的能量被基质材料吸收;泵浦波长范围内的部分能量因与晶体泵浦能带不匹配而被基质材料吸收;晶体的量子亏损与内损耗。这些因素使晶体内热量沉积,并形成温度梯度、应力梯度及形变。因此,在计算LD端面泵浦Yb:YAG方形晶体的热透镜焦距时,考虑到的主要因素为温度梯度、端面形变和热致双折射[15]。

温度梯度、热致双折射、端面形变造成了热透镜效应,它们产生的热透镜焦距分别为:

式中:Kc为晶体热导率;dn/dT为热光系数;Cφ,r为弹性系数;αT为热膨胀系数;α为吸收系数;Pph为泵浦光功率的致热功率,其与泵浦功率关系如下。

式中:ξ为热转化效率。由公式(10)~(12)可得综合热透镜焦距为:

相对于温度梯度带来的热透镜效应,热应力双折射与热形变产生的热透镜效应十分微弱[15],因此,只关注温度分布时热透镜焦距随功率的变化,如图10所示,公式(14)为简化后只考虑温度梯度的热透镜效应。

-

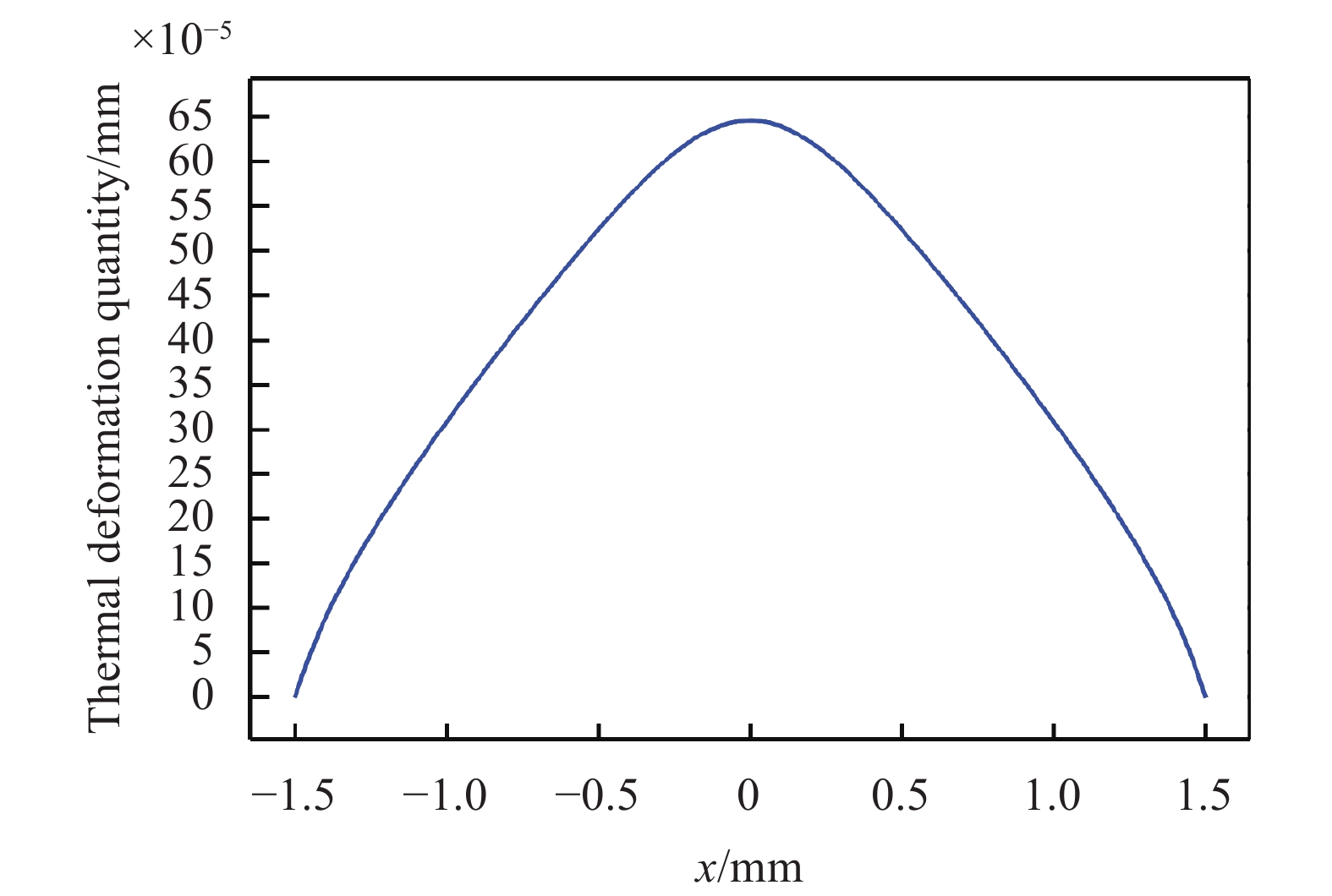

考虑到晶体周边恒温冷却、通光面与空气热交换,建立了更符合激光二极管端面泵浦Yb:YAG晶体实际工作状态的热模型,利用泊松方程和有限元分析法,对激光二极管端面泵浦Yb:YAG方形晶体的温度场分布进行了分析,并进一步计算了Yb:YAG晶体内由非均匀温升引起的的应力场以及热形变场的变化情况,最后得出一定条件下热透镜焦距随功率变化的曲线图。当激光二极管泵浦功率为50 W、泵浦光高斯半径为400 μm时,晶体尺寸为3 mm×3 mm×4 mm、掺杂浓度为5.0 at.%的Yb:YAG晶体端面的最高温升为59.2 K,最大热形变量为0.64567 μm,晶体内稳定时最大应力为2.426×107 N/m2,热透镜焦距为19.99 mm。此外,最大温升会随着高斯阶次和功率的增大、光斑半径的减小而提高,这些量的变化实际上是功率密度的变化,故可得出最大温升与功率密度正相关的结论。与文献[4]中的实验测量结果进行比较,理论计算结果基本符合,所得结果为全固态Yb:YAG激光器的设计提供了理论依据。

Temperature field and stress field of LD end-pumped Yb:YAG crystal

doi: 10.3788/IRLA20230683

- Received Date: 2023-12-08

- Rev Recd Date: 2024-01-15

- Publish Date: 2024-03-21

-

Key words:

- thermal effect /

- temperature field /

- finite element analysis /

- Yb:YAG laser /

- end-pumped

Abstract:

DownLoad:

DownLoad: